Thermal Conductivity Analysis of Tungsten Crucibles

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 11:14

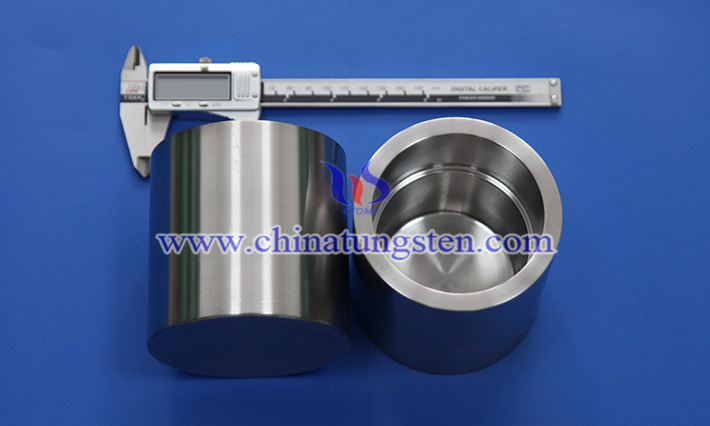

Tungsten crucibles are widely used in sapphire crystal growth, rare metal smelting, high-temperature material testing and other fields due to their excellent high-temperature stability and corrosion resistance.

In these applications, thermal conductivity, as an important physical parameter to measure the heat transfer ability of materials, directly affects the temperature field distribution, thermal stress development and overall thermal management performance of the crucible, so it is of great significance to systematically analyze the thermal conductivity of the W crucible.

The thermal conductivity of tungsten is about 170 W/(m·K) at room temperature, which is one of the highest levels among metallic materials, mainly due to its highly ordered crystal structure and high density of electron degrees of freedom. Since heat conduction in metals mainly depends on the movement of free electrons, the close arrangement of tungsten atoms provides a good transport channel for electrons, so that it still maintains relatively strong thermal conductivity even at high temperatures. In the case of tungsten crucibles, this high thermal conductivity means that they can quickly conduct an external heat source to the inner wall or quickly extract heat from the internal melt, helping to maintain temperature uniformity within the crucible and reduce local overheating.

However, the thermal conductivity of tungsten is not fixed, and it will show a certain degree of decreasing trend with increasing temperature. Above 1000°C, the average free path of free electrons is limited due to the intensification of lattice thermal vibration, resulting in a decrease in thermal conductivity, which may drop to about 100~120 W/(m·K). Although this variation is common in metals, it requires special attention in the practical use of tungsten crucibles. For example, in crystal growth processes, if the temperature field is not properly controlled, a decrease in thermal conductivity can lead to uneven temperature gradients, resulting in crystal growth defects or stress concentrations.

In addition, the actual thermal conductivity of the W crucible is also affected by various factors such as processing state, density, impurity content, etc. If there are micropores or poor intergrain bonding during the sintering process of the crucible prepared by powder metallurgy, the overall thermal conductivity may be reduced. In order to pursue thermal field accuracy, some high-end applications even require tungsten crucibles to be prepared with high density and high purity to get as close as possible to the ideal metal thermal conductivity standard. Experimental studies have shown that the thermal conductivity of tungsten may decrease by more than 5% for every 1% decrease in purity, so it is of great significance to improve the thermal conductivity of the raw material and optimize the sintering process.

In the composite thermal field system, tungsten crucible is also often used at the same time with low thermal conductivity materials such as graphite and ceramics to form a certain thermal shield or temperature difference control structure. In this construction, the W crucible can be used to create rapid heating or cooling zones due to its high thermal conductivity properties, while the perimeter insulation is used to direct the heat flow. This design is widely used in precision thermal field control equipment such as sapphire crystal furnaces and high-temperature sintering furnaces.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com