Analysis of Heat Transfer Performance of Tungsten Crucible

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 11:17

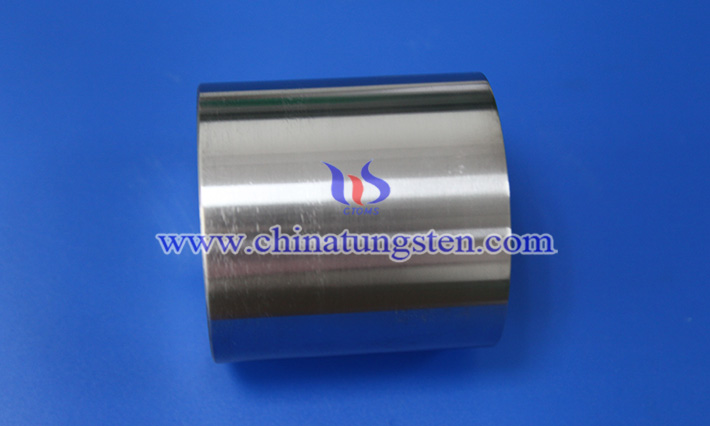

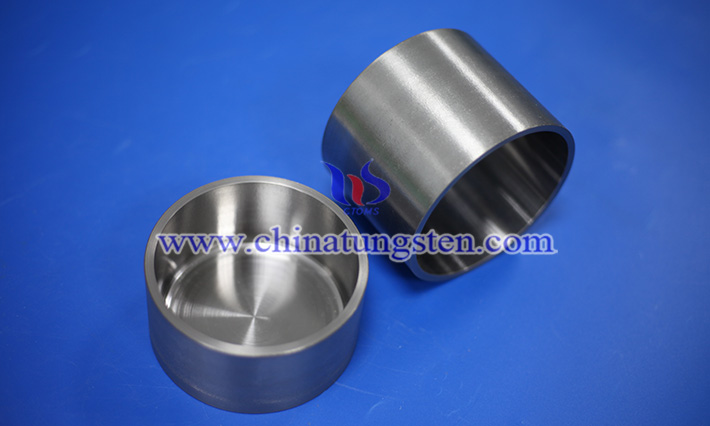

As an important part of the process of carrying molten metal, crystal growth, high-temperature evaporation, etc., tungsten crucible must not only have excellent high-temperature stability and chemical inertness, but also have good heat transfer performance to ensure the thermal efficiency of the process and the uniformity of temperature control.

The intrinsic thermal conductivity of tungsten is about 170 W/(m·K) at room temperature, which is among the highest among all metallic materials, which means that it has an extremely strong ability to transfer heat. In high-temperature applications, this feature can effectively improve the heating efficiency and cooling rate of the crucible. For example, during the growth of sapphire crystals, heat needs to be rapidly transferred from the heating source through the tungsten crucible to the crystal seed area to achieve a stable temperature gradient to control the nucleation and growth of the crystal. The high thermal conductivity of the W crucible plays a central role in this process, not only by rapidly transferring heat energy, but also by making the internal heat distribution more uniform, thus reducing the risk of crystal defects caused by temperature fluctuations.

However, the thermal conductivity of tungsten does not remain constant at all temperatures. In the process of increasing temperature, the increased vibration of the lattice will interfere with the movement of free electrons, causing their thermal conductivity to gradually decrease. For example, above 1500°C, the thermal conductivity of tungsten may drop to about 100~120 W/(m·K). Nevertheless, the heat transfer ability of tungsten at high temperatures is still significantly better than that of most ceramic or graphite materials, which makes tungsten crucibles still have obvious advantages in high temperature and high heat flux applications.

In addition to intrinsic thermal conductivity, the heat transfer performance in practical applications is also affected by the crucible structure, surface state, and material density. If the tungsten crucible manufactured by the powder metallurgy method is not densified enough during the sintering process, and there are micropores or cracks, the heat flow will scatter as it passes through these discontinuous areas, resulting in a decrease in the effective heat transfer rate. In order to improve the overall heat transfer efficiency, modern processes often use a combination of cold isostatic pressing and high-temperature sintering to ensure the compactness and continuity of the crucible structure, thereby improving its overall heat transfer capacity.

In addition, the surface treatment process of the W crucible will also have a certain impact on the heat transfer effect. For example, the smooth inner wall after mechanical polishing can reduce the interfacial thermal resistance and improve the heat exchange efficiency between the melt and the crucible. Formation of an oxide layer or corrosion-resistant coating on the surface may introduce an additional thermal resistance layer that needs to be weighed against the effects of heat transfer and corrosion resistance in use.

In some multi-layer thermal field systems, tungsten crucibles often work in tandem with components such as thermal insulating materials and heat reflective layers. At this time, tungsten material not only plays the role of high-temperature bearing, but also the "thermal conduction bridge" for rapid and efficient heat transfer. For example, in crystal drawing or high-temperature sintering furnaces, the heat generated by the external heating source of the crucible needs to be quickly introduced into the internal working area through the tungsten to achieve thermal field equalization and reaction rate control.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com