What Are the Surface Treatment Technologies of Tungsten Crucibles?

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 10:58

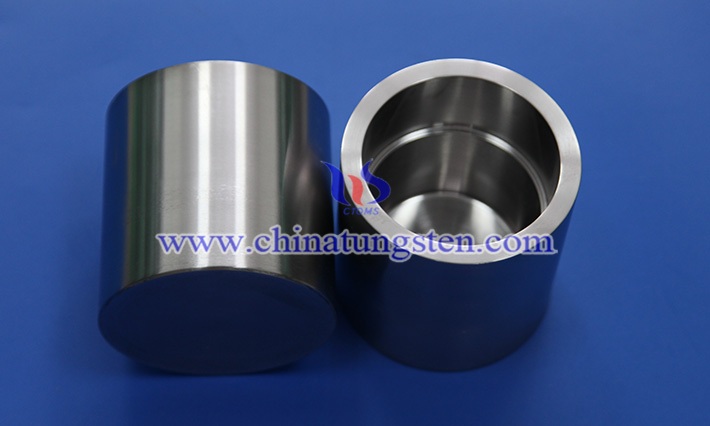

As a metal with a high melting point, tungsten is widely used in high-temperature smelting, single crystal growth, vacuum evaporation and other industrial fields due to its excellent thermal stability, corrosion resistance and high strength.

As an important vessel carrying high-temperature materials, the surface condition of tungsten crucible has a direct impact on service life, product purity and operation efficiency. Therefore, the surface treatment technologies for W crucibles have attracted extensive attention in recent years, and a variety of targeted process methods have been continuously developed.

First of all, the most common and basic surface treatment is mechanical polishing. Mechanical means such as grinding wheels, abrasive belts or slurries remove oxide layers, processing marks and microscopic cracks on the surface of the crucible to make the surface smoother. This treatment not only reduces the surface roughness, but also reduces the local failure caused by microcracks that may occur in high-temperature use, and prolongs the life cycle of the crucible. In addition, the smooth surface prevents the molten metal from adhering to the inner wall of the crucible, improving metal recovery and cleaning efficiency.

Secondly, electrochemical polishing technology is also gradually applied to the precision surface treatment of tungsten crucibles. This process achieves a mirror effect by applying an electric current to tungsten in a specific electrolyte that dissolves the raised part of its surface. Compared to mechanical polishing, electropolishing has advantages when dealing with complex geometries, improving the overall surface condition uniformly and not introducing mechanical stress. This method is particularly suitable for crystal growth industries where surface cleanliness and finish are critical.

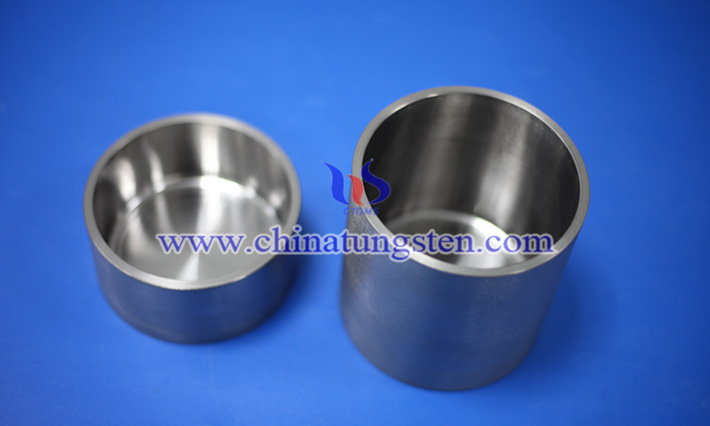

In addition, surface coating treatment is also a more cutting-edge method in recent years. Since tungsten is prone to form a brittle tungsten oxide layer in a high-temperature oxidizing environment, which affects its structural stability, its oxidation resistance can be enhanced by coating an inert or high-temperature resistant material. Common coating materials include molybdenum, silicon carbide, alumina, or rare earth oxides. This type of treatment not only delays the oxidation of the W crucible at high temperatures, but also creates a barrier to prevent some reactive melts from coming into direct contact with tungsten, improving product purity.

In addition, gas passivation treatment is also a way to improve the oxidation and corrosion resistance of tungsten crucibles. By heat treatment in a protective atmosphere such as hydrogen and argon, the oxides and impurities adsorbed on the surface can be removed, and a stable dense passivation film can be formed on the surface layer at the same time, so as to improve its overall performance. This treatment is often used as the last step before leaving the factory and helps to improve the stability of the W crucible in vacuum and high temperature conditions.

It is worth mentioning that different surface treatments can be combined according to specific application requirements. For example, in the preparation of high-purity crystals, electropolishing is often combined with an inert coating, which guarantees an extremely high finish on the crucible surface and provides a stable chemical isolation environment for maximum control of impurity sources.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com