Comparison of Different Precursors for Tungsten Nanopowder Production—Tungsten, Tungsten Trioxide, Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 November 2020 01:01

Tungsten nanopowder has been widely applied in industrial catalysis, hard materials, thermionic cathodes, and high-power batteries due to its highly oxophilic characteristics. tungsten is the hardest metal in the world, which makes it resistant to acids, alkalis, and oxygen.

Due to its intrinsic characteristics, tungsten nanopowder shows high surface area, low vapor pressure, unusual quantum confinement, and grain boundary effects, and hence require lower sintering temperatures. Tungsten nanopowder can be employed in nanodevices with electrodes, chemical sensors, biomedical sensors, phosphors, and anti-static coatings. Therefore, it is important to produce tungsten nanopowders with various morphologies and sizes. Various methods such as chemical vapor synthesis, solvothermal decomposition, plasma expansion, epitaxial growth, solution combustion synthesis, and molten salts have been reported for the synthesis of tungsten nanopowder.

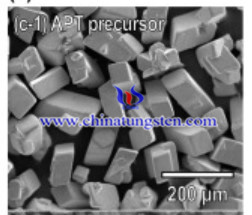

Tungsten nanopowder was fabricated by radio-frequency (RF) induction thermal plasma using three different precursors: commercial tungsten (W), tungsten trioxide (WO3), and ammonium paratungstate (APT). APT was found to the be the best precursor since the W nanopowder synthesized showed the smallest and most homogenous nanoparticles.

Experimental procedures

commercial tungsten (W), tungsten trioxide (WO3), and ammonium paratungstate (APT) were used as starting material for production of tungsten nanopowders. Ar (99.999%) in the RF induction thermal plasma was used as the central gas, sheath gas, carrier gas, and quenching gas. H2 (99.999%) was also used as the reducing agent along with Ar. The RF induction thermal plasma system consisted of an RF power supply (30 kW, 4 MHz), a plasma torch, a reactor chamber, a powder-feeding system, powder-collecting sintered-metal filters.

The starting materials were fed into the RF induction thermal plasma under the experimental conditions listed in Table 1. In the table, “0 SLPM” corresponds to the absence of H2. All the other conditions were the same for all the experiments. Prior to precursor feeding, the reactor chamber was purged with Ar for 30 min and pre-conditioned to the required temperature for 20 min until the system reached a steady level. Once the precursor was fed, the precursor particles were carried into the plasma flame by Ar in the powder-feeding system. The precursor particles were vaporized by the plasma flame and quenched rapidly by the quenching gas to accelerate the nucleation kinetics of the nanopowder synthesis. The synthesized nanopowder was collected by the powder-collecting sintered-metal filters (pore size = 1 μm).

Finally, the crystalline structure, morphology, and particle size of the as-prepared tungsten nanopowders were analyzed by X-ray diffraction, field emission scanning electron microscopy, and transmission electron microscopy.

To sum up, tungsten nanopowders using three different commercially available precursors were synthesized by RF induction thermal plasma in the presence and absence of H2. The crystalline structures and morphologies of these powders were investigated. The W nanopowder synthesized using the W precursor in the presence of H2 gas consisted of W nanoparticles. On the other hand, in the absence of H2, the synthesized powder consisted of spherical W microparticles covered by W nanoparticles. In the case of the WO3 and APT precursors, W nanopowders were obtained when H2 was used as the reductant, and the powders synthesized in the absence of H2 showed WO3 crystalline structure. APT was found to the be the best precursor since the W nanopowder synthesized using the APT precursor showed the smallest and most homogenous nanoparticles

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com