Synthesis and Characterization of Solvothermal Processed Calcium Tungstate Nanomaterials from Alkoxide Precursors

- Details

- Category: Tungsten Information

- Published on Monday, 13 July 2015 16:30

An evaluation of calcium tungsten oxide (CaWO4) nanoparticles’ properties was conducted using the powders generated from an all-alkoxide solvothermal (SOLVO) route. The reaction involved a toluene/pyridine mixture of tungsten(V) ethoxide ([W(OEt)5]) with calcium bis(trimethyl silyl) amide ([Ca(N(Si(CH3)3)2]) modified in situ by a series of alcohols (H-OR) including neo-pentanol (H-OCH2C(CH3)3 or H-ONep) or sterically varied aryl alcohols (H-OC6H3R2-2,6 where R = CH3 (H-DMP), CH(CH3)2 (H-DIP), C(CH3)3 (DBP))]. Attempts to identify the intermediates generated from this series of reactions led to the crystallographic identification of [(OEt)4W(μ-OEt)2Ca(DBP)2] (1). Each different SOLVO generated “initial” powder was found by transmission electron microscopy (TEM) and powder X-ray diffraction (PXRD) to be nanomaterials roughly assigned as the scheelite phase (PDF 00-041-1431); however, these initial powders displayed no luminescent behavior as determined by photoluminescence (PL) measurements. Thermal processing of these powders at 450, 650, and 750 °C yielded progressively larger and more crystalline scheelite nanoparticles. Both PL and cathodoluminescent (CL) emission (422–425 and 429 nm, respectively) were observed for the nanomaterials processed at 750 °C. Ion beam induced luminescence (IBIL, 478 nm) appeared to be in agreement with these PL and CL measurements. Further processing of the materials at 1000 °C, led to a coalescence of the particles and significant improvement in the observed PL (445 nm) and CL measurements; however, the IBIL spectrum of this material was significantly altered upon exposure. These data suggest that the smaller nanoparticles were more stable to radiation effects possibly due to the lack of energy deposits based on the short track length; whereas the larger particles appear to suffer from radiation induced structural defects.

Tungsten Powder Manufacturer&Supplier:ChinatungstenOnline-www.tungsten-powder.com

Tel.:865925129696;Fax:865925129797

Email:sales@chinatungsten.com

Tungsten&MolybdenumInformationBank:http://i.chinatungsten.com

TungstenNews&TungstenPrices,3GVersion:http://3g.chinatungsten.com

MolybdenumNews&MolybdenumPrice:http://news.molybdenum.com.cn

Luminescence Properties of Calcium Tungstate Activated by Lanthanide(III) Ions

- Details

- Category: Tungsten Information

- Published on Monday, 13 July 2015 16:26

Calcium tungstate phosphors activated by the Ln3+ ions (Ln=Pr, Nd, Tb, Yb) were synthesized by a traditional high-temperature solid-state method. The crystal structures and morphologies of the products were characterized by scanning electron microscopy (SEM), X-ray powders diffraction (XRD) and infrared spectra (FT-IR). The samples were found to show luminescence properties (down-conversion, DC, at excitation wavelength 254 nm and up-conversion, UC, at excitation wavelength 980 nm). CaWO4 doped with Tb3+/Yb3+showed green DC and UC luminescence characteristic of Tb(III) ion in the range of 470-660 nm, cor-responding to the 5D4→7F6,5,4,3,2 electronic transition. CaWO4 doped with Pr3+/Yb3+showed week blue, green and red (DC and UC) luminescence of Pr(III) ion, in the wavelength region of 450-700 nm. Emission peaks were ascribed to the 3P1→3H4,5,6, 3P0→3H4,5,6, 3P1→3F2 and 3P0→3F2 transitions, respectively. CaWO4 doped with Nd3+/Yb3+phosphor emitted orange UC luminescence at 450-690 nm (2P3/2→4I15/2, 4G7/2→4I9/2,11/2,13/2) and strong near-infrared UC luminescence at 720-900 nm (4F7/2+4S3/2→4I9/2, 4F5/2+2H3/2→4I9/2, 4F3/2→4I9/2) which is the characteristic of Nd(III) ion.

Tungsten Powder Manufacturer&Supplier:ChinatungstenOnline-www.tungsten-powder.com

Tel.:865925129696;Fax:865925129797

Email:sales@chinatungsten.com

Tungsten&MolybdenumInformationBank:http://i.chinatungsten.com

TungstenNews&TungstenPrices,3GVersion:http://3g.chinatungsten.com

MolybdenumNews&MolybdenumPrice:http://news.molybdenum.com.cn

Tungsten Used in Medical Imaging Technology

- Details

- Category: Tungsten Information

- Published on Monday, 13 July 2015 15:18

Due to tungsten alloy has high density, excellent radiation attenuation properties, and environmental friendly, it is widely used in medical imaging technology. Medical imaging technology has tended to become more integrated over the past decade. While combined Positron Emission Tomography and Magnetic Resonance Imaging (PET/MRI) is rapidly gaining popularity, no commercial systems for combining the complementary functional imaging techniques of Single Photon Emission Computed Tomography (SPECT) and MRI have been developed. This is mainly due to the physical space constraint, magnetic incompatibility of collimators and the required rotation mechanism inside the MRI bore. Some approaches investigated this integration but no one focused on the development of preclinical SPECT systems and their integration with pre-clinical MRI without compromising image quality and taking into account the MR-compatibility of the collimator material. This study investigates eddy currents in the collimator due to the magnetic field gradients, for different resistivities of tungsten, for small animal SPECT/MRI. Collimator resistivity can be tuned nowadays through tungsten additive.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Shielding for Beam Collimators

- Details

- Category: Tungsten Information

- Published on Monday, 13 July 2015 15:14

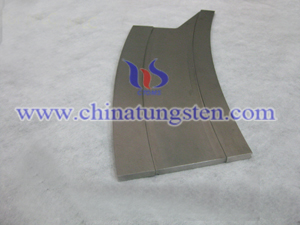

Beam collimators, which are usually made of tungsten alloy shielding, including linear accelerators and tungsten multi-leaf collimators and so on. Beam collimators are 'beam direction' devices used in the X-ray tube housing, along with an arrangement of mirrors and lights, in such a way that the light and X-ray fields match each other. They are made of lead shutters which completely absorb the photons, and thus reduce patient dose as well as focus the radiation accordingly to the area of interest. They allow different projections of X-ray fields.

In linear accelerators (linac), the primary collimator may be constructed of depleted uranium (DU) as this material is approximately 1.6 times more dense than lead. The secondary motorised collimators which greater define the beam shape are constructed of tungsten. Multi-leaf collimators (MLCs) which are now in widespread use in medical linacs consist of two collimator banks of thin tungsten 'leaves' with each bank consisting of 40 to 80 leaves (so a total of 80 to 160 leaves). This allows each tungsten leaf to move independently under computer control. MLCs allow even more diverse field shapes to be created which can shield organs at risk whilst allowing the complex shape of the tumour bed to be irradiated to allow maximum cell kill.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Advantages of Tungsten Polymer Shielding System

- Details

- Category: Tungsten Information

- Published on Monday, 13 July 2015 15:11

Tungsten polymer Shielding’s density approaching twice that of high density Lead Blankets of similar thickness. Highly flexible and can be molded/formed into any shape. Often competitively priced to lead alternatives.

The advantages of tungsten polymer shielding system:

- Provides approx. 75% Attenuation as compared to solid lead

- Attenuation of 175% compared to a high density lead blanket

- Priced competitively to lead for many applications

- Available as a blanket, ribbon wrap or molded shapes; flexible or rigid

- Cut materials to fit without needing to seal edges - no residue

- Included fasteners, grommets, locking devices, etc., as required

- Improved fit-up --- molded applications typically will yield much higher reduction factors - less weight with same impact

- Tested to 550°F/288°C

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Disulfide Producing

- Details

- Category: Tungsten Information

- Published on Friday, 10 July 2015 18:11

There are three ways for producing tungsten disulfide which are the following:

The first method: tungsten disulfide produces by firing decomposition method. Firstly, stirring tungsten acid and ammonia water with at 57 ~ 60 ℃ to react for three hours, heat prevention more than 16 hours of natural sedimentation. After reaction get the sodium tungstate then to react with hydrogen sulfide gas, to generate tetrathiotungstate acid. Finally after calcination, the tetrathiotungstate acid will decompose to tungsten disulfide. During the reaction, heating should at 100 ~ 200 ℃ / hr temperature gradient from room temperature to of 700 ~ 1200 ℃. Then after heat preservation for 24 to 48 hours, then at 30 ~ 110 ℃ / hour temperature gradient descending to room temperature, and finally crushing the material. Related chemical reaction of the reaction equation is as follows:

H2WO4 + 2NH3 • H2O → (NH4) 2WO4 + 2H2O

(NH4) 2WO4 + 4H2S → (NH4) 2WS4 + 4H2O

2 (NH4) 2WS4 + 3O2 → 2WS2 + 4NH3 + 2S + 2SO2 + H2O

The second method: putting sulfur vapor through the red-hot tungsten can form tungsten disulfide

The third method: mixing tungsten with stoichiometric sulfur at 800 ℃ for 24 hours in a nitrogen atmosphere can be formed WS2. If changing the reaction conditions, namely in 6MPa reacted with 1800 ℃, can be formed orthorhombic WS2.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Trisulfide

- Details

- Category: Tungsten Information

- Published on Friday, 10 July 2015 18:08

Sulphur is a nonmetallic chemical element, and elemental sulfur is usually kind of yellow crystals, also known as sulfur. There are many elemental sulfur allotropes, such as rhombic sulfur, monoclinic sulfur and sulfur elasticity. Sulfur is an important element in the human body protein for human life is important. Sulfur is mainly used in fertilizers, gunpowder, lubricants, pesticides and anti-fungal agent production.

Tungsten trisulfide is a reddish brown powder and its chemical formula is WS3, molecular weight 280.11, CAS registry number 1215-19-8. Tungsten trisulfide slightly soluble in water, soluble in hot water, alkali metal carbonates and alkali metal hydroxides, in addition it can generate colloidal solution in hot water.

Producing tungsten trisulfide can use thermal decomposition method of ammonium tungstate (a kind of hydrogen sulphide saturated ammonium tungstate). Or making hydrogen chloride to react with ammonium tetrathiotungstate obtains tungsten trisulfide.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Disulfide Lubricant Advantages

- Details

- Category: Tungsten Information

- Published on Friday, 10 July 2015 18:06

Tungsten disulfide has similar lubricating properties with graphite, is widely used as a lubricant. And tungsten disulfide as a lubricant performance is better than molybdenum disulfide, mainly due to it properties which is low friction coefficient(0.03), high resistance to extreme pressure and oxidation resistance, namely, tungsten disulfide at 450 ℃ in the air begins to decompose, until 650 ℃ completely decomposed. On the other hand, at1100 ℃ in the vacuum it begins to decompose, until 2000 ℃ completely decomposed. This performance is conducive tungsten disulfide apply in high-temperature, high pressure, high speed, high load, as well as in chemical active media device operation.

Meanwhile tungsten disulfide on the metal surface has a good adsorption capacity can be added to make the original lubrication in engineering plastics or it can mix with volatile solvent sprayed on the metal surface, to improve the life of mold in press forging and workpiece surface finish.

Tungsten disulfide also can mix with the oil, fat oil to form tungsten disulfide, tungsten disulfide grease, wax and other tungsten disulfide solid lubricating block and lubricating film.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Disulfide Application

- Details

- Category: Tungsten Information

- Published on Friday, 10 July 2015 18:03

Tungsten disulfide is widely used in lubricant field, at the same time because its good performance in cracking, long service life and catalytic activity is stable and reliable, so it also be used in petroleum catalysts. Where it can serve as a hydrogen desulfurization catalyst, on the other hand it can be used in the polymerization, heavy Catalyst whole, hydration, dehydration and other processes of hydroxylation, so it has been widely applied to the oil refinery.

Tungsten disulfide can also apply in inorganic materials preparation technology which is the nano-tungsten disulfide can be used as an efficient catalyst. Since it can form the novel compounds capable with sandwich structure, nano tungsten disulfide monomolecular layer may be formed two-dimensional material, and be able to re-stack "structure room floor"with very large space the new particulate material, and in the process of re-stacking inserted substances can be added to make it a catalyst or sensitive display and superconducting materials, its huge internal surface area easily mixed with accelerator, a new type of highly efficient catalysts.

Tungsten disulfide also can as fuel cells, organic electrolyte rechargeable battery, as well as sensors’ anode and used to make nano-ceramic composite materials.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Nano Tungsten Disulfide Application

- Details

- Category: Tungsten Information

- Published on Friday, 10 July 2015 18:01

Tungsten disulfide is used as solid lubricants, dry film lubricants, self-lubricating composite material, and wherein the nano tungsten disulfide solid lubricant is the best. Mainly because tungsten disulfide nano particles has low friction coefficient, high compressive strength, and with acid erosion resistance, good load performance, non-toxic, wide temperature range, long life and other advantages of lubrication and so it is widely used.

Meanwhile tungsten disulfide nano particles can also be used as an additive to produce high-performance lubricants. After the studies found adding the right amount of tungsten disulfide nano particles in the lubricant can greatly improve the lubricating properties of the lubricant. Under the same conditions, there will improve lubricating properties of adding nanometer WS2 base oil than conventional particles added base oil and has good dispersion stability, friction factor can be reduced by 20% to 50%, the film strength can be increased by 30% ~ 40%, which is far superior lubricating properties than molybdenum disulfide nano particles. With the addition of a lubricant nano particles combines the advantages of solid lubrication and lubrication, which is expected to realize from room temperature to high temperature (over 800 ℃) full lubrication. Therefore, tungsten disulfide nano particles can be used as additives synthesis new lubrication system which has broad application prospects.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com