What Are Challenges Faced in Processing Pure Tungsten Sheets?

- Details

- Category: Tungsten's News

- Published on Tuesday, 31 December 2024 15:29

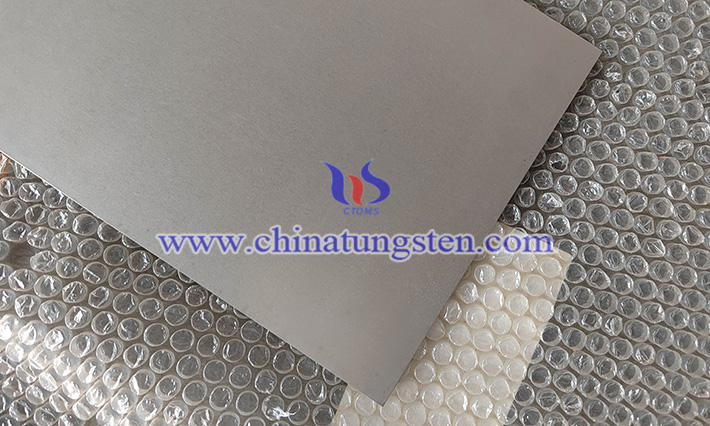

Pure tungsten sheets are known for their exceptional physical and chemical properties, including a high melting point (3410°C), high density, excellent thermal and electrical conductivity, and remarkable resistance to high temperatures.

While these properties make tungsten a valuable material for various industrial applications, they also pose significant challenges during its processing. Below are the primary difficulties encountered in processing tungsten sheets:

1. High Melting Point and Hardness

Tungsten's extremely high melting point and intrinsic hardness make it difficult to machine and shape. Conventional cutting and forming tools tend to wear out quickly, and advanced techniques such as laser cutting or EDM (Electrical Discharge Machining) are often required. However, these methods increase production costs and require specialized equipment.

2. Brittleness at Room Temperature

While tungsten exhibits excellent strength at high temperatures, it is brittle at room temperature. This brittleness can lead to cracking or breaking during mechanical processing, such as rolling, bending, or punching. Special care must be taken to avoid stress concentrations, and intermediate annealing is often necessary to relieve internal stresses during processing.

3. High Density and Weight

Tungsten’s high density makes it challenging to handle during processing. Equipment needs to be robust enough to accommodate the material's weight, and careful design considerations are required to ensure uniformity in thickness and dimensions.

4. Poor Weldability

Welding pure tungsten is difficult due to its high melting point and sensitivity to impurities. The presence of oxygen, carbon, or other contaminants can degrade the weld quality and lead to porosity or cracking. Vacuum or inert gas environments are typically required for successful welding, adding complexity to the process.

5. Surface Finish and Precision Requirements

Pure tungsten sheets are often used in applications requiring high precision and smooth surface finishes, such as electronics or medical devices. Achieving these standards is challenging because of tungsten’s tendency to develop microcracks or rough edges during machining. Polishing and finishing processes require extra effort and time.

6. Oxidation During High-Temperature Processing

When processed at high temperatures, tungsten is prone to oxidation, forming tungsten oxides that can compromise the material’s properties. Protective atmospheres, such as inert gases or vacuum, are necessary to mitigate oxidation, increasing processing complexity and cost.

Chinatungsten Online is a professional manufacturer of tungsten and molybdenum for nearly thirty years. We can supply tungsten products in customized designs. Please free feel to contact us when you got the purchasing plans.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com