How Do Tungsten Copper Alloys Impact Their Performance in Heat Sink Applications?

- Details

- Category: Tungsten's News

- Published on Monday, 15 April 2024 15:46

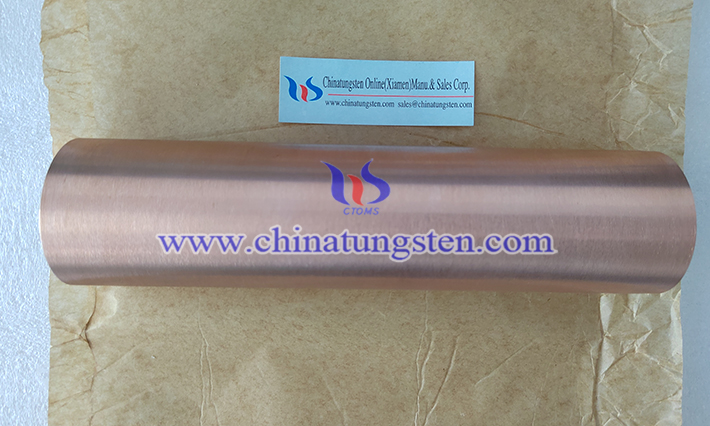

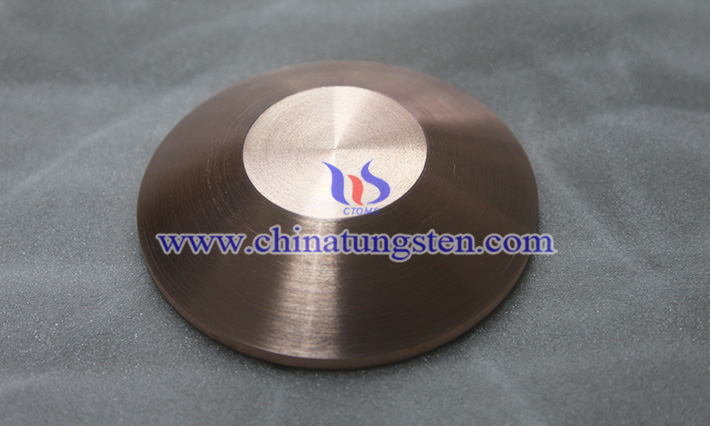

The electrical conductivity properties of tungsten copper alloys play a crucial role in determining their performance in heat sink applications. They are renowned for their excellent thermal conductivity, but their electrical conductivity characteristics also contribute significantly to their effectiveness in dissipating heat from electronic components.

In heat sink applications, efficient thermal management is essential to prevent the overheating of electronic devices, which can lead to performance degradation or even failure. WCu alloys, with their high electrical conductivity, facilitate the rapid and uniform distribution of heat away from heat-generating components. This ensures that heat is efficiently dissipated throughout the heat sink, minimizing hot spots and maintaining optimal operating temperatures.

Moreover, the electrical conductivity of the alloy enables them to function effectively in applications where electrical insulation is required. By providing electrical conductivity while simultaneously conducting heat away from electronic components, tungsten copper heat sinks offer a versatile solution for thermal management in various electronic devices and systems.

The electrical conductivity properties of WCu alloys also influence their compatibility with electrical components and circuits. In applications where heat sinks are integrated into electrical circuits or devices, such as power electronics or semiconductor devices, the electrical conductivity of the heat sink material must be carefully considered to ensure proper electrical performance and compatibility with the system.

Furthermore, the electrical conductivity of WCu alloys can impact their electromagnetic interference (EMI) shielding capabilities. High electrical conductivity allows the heat sink to effectively dissipate electromagnetic radiation, reducing the risk of interference with nearby electronic components or systems.

Overall, the electrical conductivity properties of tungsten copper alloys are critical for their performance in heat sink applications. By facilitating efficient heat dissipation, ensuring electrical compatibility, and providing EMI shielding capabilities, tungsten copper heat sinks contribute to the reliable and effective thermal management of electronic devices and systems.

Chinatungsten Online is a professional manufacturer of tungsten and molybdenum for nearly thirty years. We can supply tungsten copper heat sink materials as per the drawings. Please free feel to contact us when you got the purchasing plans.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com