Oxidation Behavior of W-Cr-Ti Ternary Alloys

- Details

- Category: Tungsten's News

- Published on Saturday, 22 April 2023 15:43

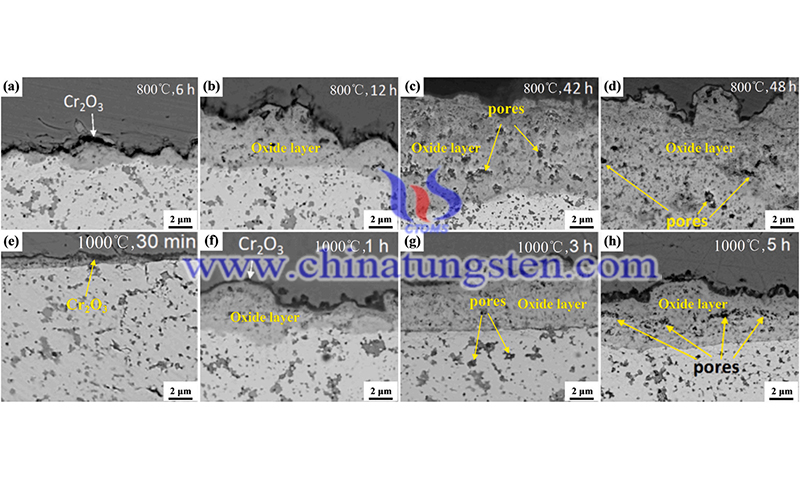

Garcia et al. produced W-Cr-Ti ternary alloys—WCr12Ti2.5 (wt%) alloys by MA and hot isostatic pressing (HIP) techniques and investigated the oxidation behavior of the alloy. The results showed that the Δ m/S of the WCr12Ti2.5 alloy was 1.25 × 10-2 to 4 × 10-2 times higher than that of the W-Cr alloy during the first 15 h of oxidation at 800 °C. In addition, the former is 2 × 10-2 to 5 × 10-2 times higher than the latter for the first 5 h of oxidation at 1000 °C. With increasing oxidation time, the oxide layer of the WCr12Ti2.5 alloy becomes thicker and its porosity gradually increases. In addition, the oxidized alloy has a similar cross-sectional structure, consisting of black, dark gray and light gray phases from inside to outside, respectively.

Cross-sectional and EDS mapped images of the alloy after isothermal oxidation show that the black outermost layer is Cr2O3 and the dark gray intermediate layer is composed of Ti, W, small amounts of Cr and other oxides. In addition, the bottom of the Cr2O3 layer consists of Cr2WO6 and Ti2CrO5 layers, followed by a mixed region consisting of Ti2CrO5 and WO3. This indicates that the diffusion rate of Ti4+ and Cr3+ cations outward is greater than that of W3+ cations.

More importantly, there is a large amount of irregular scale growth in the form of "waves" in the outer region, and its thickness is not uniform. This is due to the large amount of oxides generated and compressive stresses released during the oxidation process, which led to the cracking of the thinner regions of the Cr2O3 layer. As a diffusion barrier, the Ti2CrO5 layer inhibits the internal diffusion of O2-, which gives the alloy better oxidation resistance than the W-Cr alloy. For the oxidation behavior, although both the internal oxidation zone and the bulk alloy zone are relatively smooth, there are still some holes in them. This indicates that some oxygen still enters the alloy and oxidizes the W-rich phase.

Reference: Fu T, Cui K, Zhang Y, et al. Oxidation protection of tungsten alloys for nuclear fusion applications: A comprehensive review[J]. Journal of Alloys and Compounds, 2021, 884: 161057.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com