Using Novel Molybdenum Metal-Organic Framework as Efficient Catalyst

- Details

- Category: Tungsten's News

- Published on Wednesday, 29 June 2022 12:03

Recently, researchers utilized a novel molybdenum metal-organic framework as an efficient and reusable catalyst. In this study, metal-organic frameworks based on molybdenum and piperidine-4-carboxylic acid were synthesized by a simple solvothermal method and used as an efficient catalyst for the production of biodiesel from oleic and palmitic acids via esterification reactions.

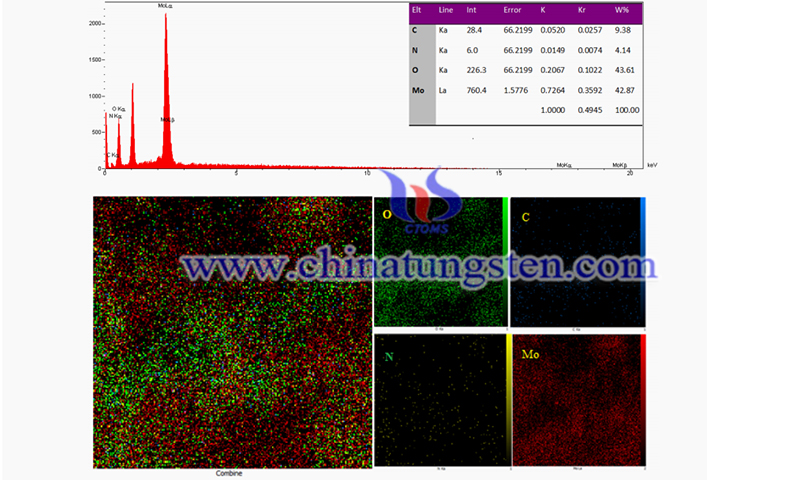

The prepared catalysts were characterized by XRD, FTIR, TGA, DSC, BET, SEM, TEM, ICP-OES, X-ray maps, and EDX analysis. The obtained Mo-MOF catalysis exhibited a rod-like morphology with a specific surface area of 56 m2/g and thermal stability up to 300 °C. The solid catalysts exhibited high activity in the esterification of oleic and palmitic acids. Moreover, the catalysis can be simply recovered and efficiently reused several times without significant activity loss, and the obtained results also indicate that the MOF can be used for proper and fast biodiesel production.

(Credit: Arash Ghorbani/Nature. Scientific Reports)

Due to the increasing environmental pollution and global warming caused by fossil fuels, many studies are seeking to develop renewable energy technologies. In this context, biodiesel is considered to have the greatest potential to reduce particulate matter, CO2, and greenhouse gas emissions, as its high octane rating and low viscosity make it a promising and economically viable alternative to common fossil fuels.

Biodiesel is a renewable energy source that can be produced by transesterification of triglycerides from biomass oils (e.g., vegetable oils and animal fats) with methanol. Conventional biodiesel production methods utilize homogeneous phase conditions in the presence of alkaline or acid catalyzes such as sulfuric acid and sodium hydroxide. These homogeneous systems suffer from limitations such as reactor corrosion, difficulty in catalysis recovery and recycling, and environmental contamination. In this case, heterogeneous catalysis offers more advantages than homogeneous catalyzes, such as recyclability, ease of separation and purification processes, high glycerol purity, and non-corrosiveness.

To date, a number of the solid acid-base catalyst with tunable structures and surface functions have been provided, many of which show high catalytic activity for biodiesel production. Heterogeneous solid base catalysis typically provides higher rates under milder reaction conditions compared to acid-based catalysis.

However, they cannot be used directly for oils with more than 2 wt% FFA content due to side reactions such as saponification and hydrolysis, and they reduce the catalysis activity and ester yield. Therefore, solid acid catalysis is used when treating low-quality or non-edible vegetable oils containing large amounts of FFA and water. The molybdenum metal-organic framework based catalysis is considered versatile because this metal is capable of being present on solid surfaces in different oxidation states, from Mo6+ to metallic Mo.

(Credit: Arash Ghorbani/Nature. Scientific Reports)

Anhydrous sodium molybdate, bulk MoO3, silica MoO3/B-ZSM-5 molybdenum-supported alumina, silica, silica-alumina, titanium dioxide, and carbon have been used as transesterification and esterification catalysis for the production of biodiesel from several oils, including waste oils.

Compared to bulk MoO3, alumina-supported MoO3 provides more efficient utilization of the active phase and enhanced stability to the reaction medium for leaching molybdenum.

The structure of the network is influenced by several factors, such as building blocks, solvents, temperature, pH, etc. Meanwhile, its topology mainly depends on the connectivity and symmetry of metal ions (or metal clusters) and organic nodes. Researchers found that the topology of rod MOFs is a metal-organic framework in which the metal-containing secondary building blocks consist of an infinite number of rod-linked metal-centered aggregates.

Comparison of catalyst reusability and catalytic performance of Mo-MOF. Reusability is a very important factor that determines the robustness of heterogeneous solid catalysts and its commercial potential, especially from an economic and practical point of view. Filtration and centrifugation are two methods traditionally employed in the laboratory context for the processing, separation, recovery, and recycling of heterogeneous catalysis. In addition, MOFs are often suitable as highly recyclable catalytic systems where catalysis can be easily and efficiently recovered by simple filtration or centrifugation.

The study titled “Efficient biodiesel production from oleic and palmitic acid using a novel molybdenum metal-organic framework as efficient and reusable catalyst” has been published in Nature Scientific Reports (2022) 12:10338. The study was carried out by Arash Ghorbani‑Choghamarani, Zahra Taherinia, and Yunes Abbasi Tyula.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com