Researchers Develop Crack-Free WS2 Monolayer for Flexible Electronic Applications

- Details

- Category: Tungsten's News

- Published on Tuesday, 28 June 2022 13:01

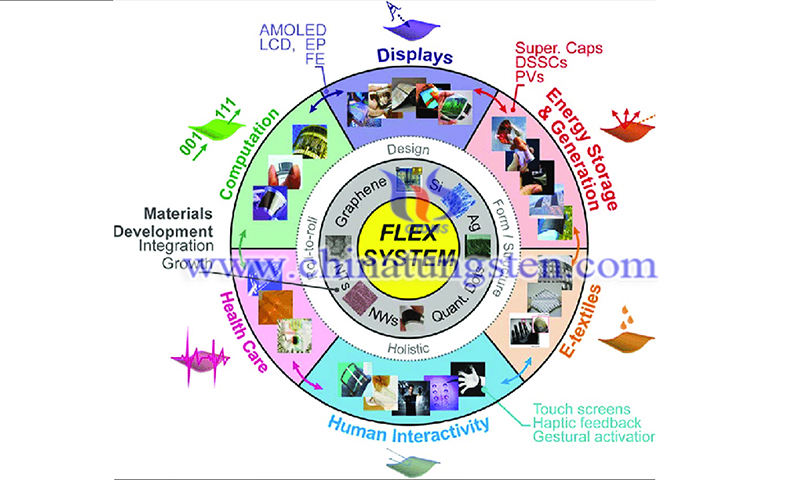

Researchers at the Indian Institute of Technology (IIT), Mandi, have developed a process to achieve a crack-free WS2 monolayer by studying the role of growing substrates, thermal stress, and defects. The results mitigate defects in chemical vapor deposition (CVD) grown two-dimensional materials while providing a platform for applications such as flexible electronic applications, neuromorphic devices, and sensors.

![]()

(Source: Qilin Cheng/Wiley)

Simultaneously, Chandra Singh of the University of Toronto and Sankha Mukherjee of IIT Kharagpur collaborated on density functional theory (DFT) simulations. The project was funded by the Indian Ministry of Manpower Development-Centre for Scientific and Technological Research and the Natural Sciences and Engineering Research Council of Canada (NSERC), the institute said in a statement.

This study shows that atomic-thick WS2 monolayers are of wide interest for their ability to carry gaps, high mobility values, and provide a platform for heterogeneous integration of multiple functions. However, device fabrication of 2D materials using these monolayers is limited by the lack of large-scale, crack-free monolayer growth.

However, researchers at IIT Mandi have demonstrated that despite defects and voids in WS2 monolayers, cracking can be avoided if CVD growth is performed on a suitable substrate (e.g., sapphire).

Highlighting the study, Viswanath Balakrishnan, associate professor at IIT Mandi School of Engineering, said, "Our team conducted a systematic investigation to characterize severe cracking in WS2 monolayer grown on different substrates by linking the thermal mismatch stress, substrate-monolayer binding energy, and the presence of defect-mediated void formation."

Divya Verma further explains, "This is critical for large-scale crack-free growth of WS2 monolayer, where defect engineering has the potential to enhance their functionality without compromising mechanical reliability."

The growth of WS2 monolayer for flexible electronic applications is also critical, as the growth temperature, growth substrate, and defect formation all affect its mechanical stability. Substrates generate residual stresses during the growth process and the effect varies as the thermal expansion coefficients of different materials can vary. Therefore, in order to achieve crack-free monolayers, the thermal mismatch stresses and the bonding energy between the substrate and the monolayer need to be optimized.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com