KIMS: Rare Earth Magnet Uses Less Neodymium

- Details

- Category: Tungsten's News

- Published on Saturday, 30 April 2022 13:01

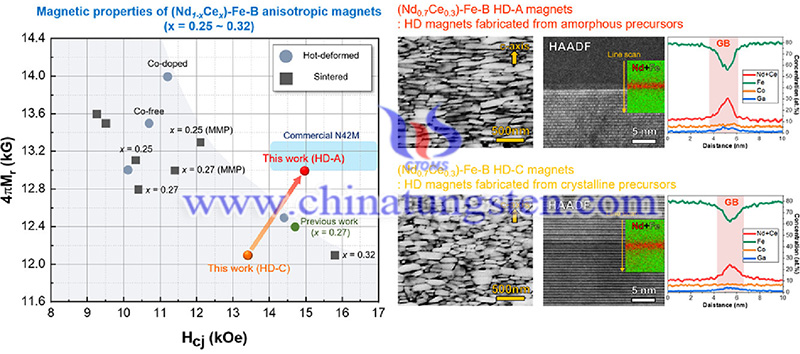

According to the Korea Institute of Materials Science (KIMS), the performance of grade 42M commercial rare earth magnet can be achieved with 30% less neodymium than before. Due to the growing demand for anisotropic Nd-Fe-B permanent magnets for high-efficiency motors for hybrid/electric vehicles and wind turbines, the shortage of Nd resources has become a serious problem.

Therefore, the challenge for the Nd-Fe-B magnet industry now is to achieve high coercivity magnetism (Hcj) and high remanence magnetism (4πMr) while reducing the neodymium content of the magnets.

Since Ce is the most abundant rare earth element, Ce has attracted attention as an alternative to Nd in magnets. However, since the Ce2Fe14B phase (4πMs = 11.7 kG, Ha = 26 kOe) has a lower intrinsic magnetism than the Nd2Fe14B phase (4πMs = 16 kG, Ha = 73 kOe), both the 4πMr and Hcj of the (Nd1-xCex)-Fe-B magnets degrade with increasing x. Previous researchers have attempted to replace rubidium with the less costly rare earth cerium, but making this substitution proved difficult.

(Credit: KIMS)

KIMS says, "In order to develop a neodymium-reduced permanent magnet, the cerium content had to be increased." Until now, as the cerium content increased, it did not prevent the deterioration of the magnetism." Part of the reason is that Ce2Fe14B is not a candidate for Nd2Fe14B magnets, which are currently available in 11.7kG and 26kOe using cerium and 16kG and 73kOe using neodymium.

According to the team, more than 24% cerium causes rare-earth magnets to develop paramagnetic (hardly magnetic) and destroys the crystal structure required for strong rare-earth-Fe-B magnets.

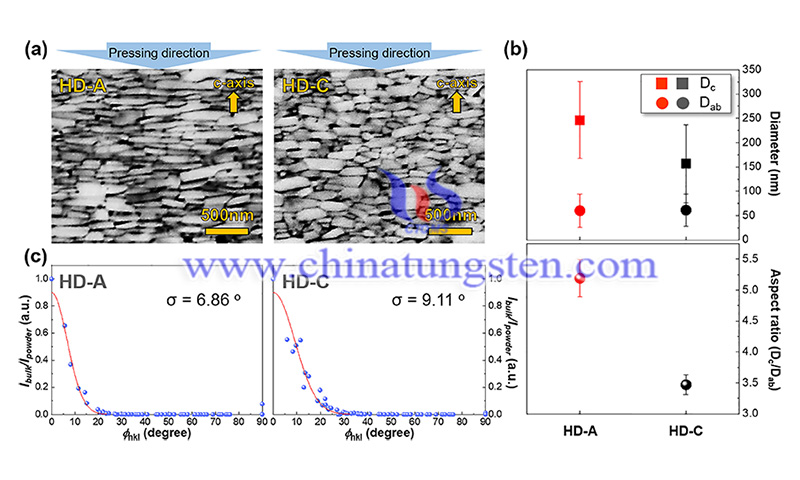

Using thermal deformation rather than sintering to form the final rare earth magnet shape is one solution because rapid cooling hinders the formation of rare earth-iron particles, but thermal deformation does not deal with the rare earth-iron particles that were already formed when the precursor powder was made by crystalline fusion.

The key step in KIMs is to increase the rotation speed, in which cooling is also accelerated, to produce amorphous precursor powders from the same feed material. The result is a powder-free of rare earth-Fe particles, which are then thermally deformed into the final magnet shape to avoid subsequent formation of rare earth-Fe particles.

The research team led by Jung-Goo Lee and Tae-Hoon Kim said they were able to successfully optimize the microstructure of the magnets by suppressing the formation of unwanted magnetic particles, KIMS said, "In addition, they were able to improve both remanence and coercivity, which are the main properties of permanent rare earth magnet. Since remanence and coercivity are a trade-off, techniques that can improve both are very useful."

(Credit: KIMS)

The work is covered in “High-performance Ce-substituted (Nd0.7Ce0.3)-Fe-B hot-deformed magnets fabricated from amorphous melt-spun powders” published in Scripta Materialia in June 2022 (Volume 214). The research was carried out by Ga-Yeong Kim, Tae-Hoon Kim, Hee-Ryoung Cha, Sang-hyub Lee, Dong-Hwan Kim, Yang-Do Kim, Jung-Goo Lee.

- Rare Earth Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com