Creating MoS2 Nanocomposites in Ecological Approach

- Details

- Category: Tungsten's News

- Published on Saturday, 09 April 2022 16:45

A research article in Chemistry of Materials suggests that controlled separation of MoS2 nanocomposites can be performed using water as a solvent, an ecological approach that is highly beneficial for industrial photovoltaic applications. Molybdenum disulfide (MoS2), like graphene, has been one of the most intensively studied materials by scientists.

MoS2 is a new family of semiconducting 2H-metal 1T-phase transition metal dichloride (TMDCs) with a lamellar intercalation structure. The synthesis of top TMDCs with a minimal number of hexagonal atomic layers is of great interest and significance for both basic research and a wide range of possible applications.

It is widely used in field-effect transistor applications and has found extensive applications in the framework of the photovoltaic industry, chemical sensing industry, and valley electronics industry. Researchers have recently been working on developing effective methods to fabricate large-area uniform MoS2 nanofilms because of their excellent electrical and optical capabilities.

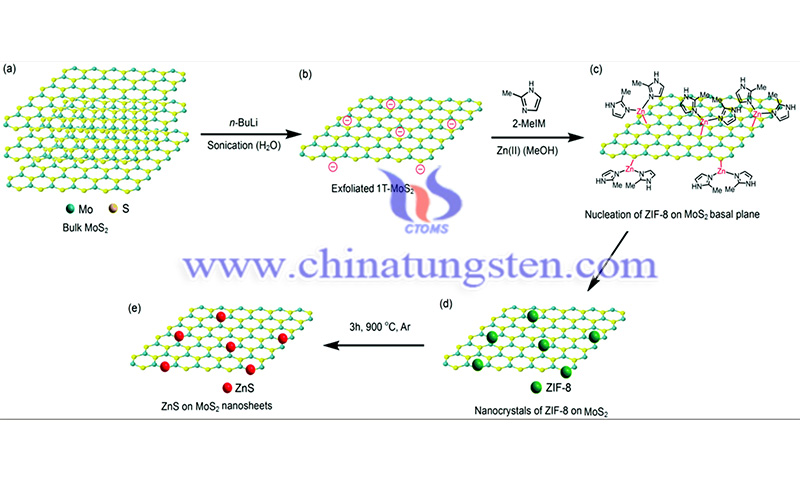

The exfoliation of MoS2 crystal structures into nanostructured sheets is a key step in generating the excellent optical mobility required for high-performance optoelectronic devices. Chemical exfoliation by ionic deposition, hydrothermal method, chemical vapor deposition of precursors, micromechanical debonding, and liquid phase exfoliation are some of the physicochemical synthesis techniques applied to MoS2 nanosheets.

The chemical exfoliation process alters the crystalline phase, destroys the conductive properties of the fabricated MoS2 nanosheets, and severely affects their optoelectronic properties. Chemical vapor deposition, hydrothermal and nano-fracturing methods are highly resource-consuming and lengthy processes that are not suitable for producing monolayer MoS2 nanosheets at a commercial scale.

LPE using organic solvents is a simple method for the large-scale production of commercial-scale 2D nanostructures. Only a few solutions have proven to be effective in exfoliating and dispersing multilayer nanosheets, such as dimethyl sulfoxide. However, due to their high boiling points, these solvents are hazardous and not suitable for the long-term development of eco-friendly methods.

Due to their challenging extraction process, there is an urgent need for a sustainable, reliable, efficient, and environmentally friendly method for successful dispersant-assisted LPE in aqueous media that allows rapid delamination of the sheets and promotes MoS2 dispersion.

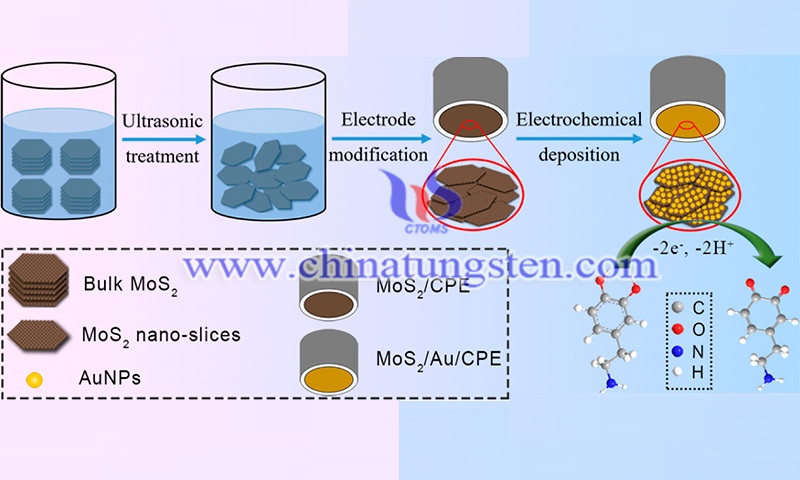

Water is an environmentally safe and biocompatible solvent, but due to its highly hydrophilic nature, it does not effectively aid in the abrasion of 2D nanomaterials. In a recent study, researchers attempted to establish a new strategy for the systematic separation of MoS2 nanocomposites in water using a bifunctional cytosine end-covered supramolecular Cy-PPG using a two-step LPE technique.

In water, dynamic light scattering (DLS) showed that Cy-PPG has a monomorphic distribution with an average hydrodynamic size of 87.16 ± 1.64 nm and a polydispersity index of 0.29, indicating that Cy-PPG can spontaneously self-assemble into forms with distinct nanostructures. powdered crystals of E-MoS2 precipitated almost completely from the solution with a Cy-PG content of less than 50%.

When the Cy-PG concentration of E-MoS2 solution exceeded 65%, the precipitation of E-MoS2 steadily decreased after sonication as the Cy-PG level increased. aqueous E-MoS2 solutions with Cy-PPG content above 65% allowed more simultaneous reactions between E-MoS2 and Cy-PPG.

Furthermore, the light transmission of E-MoS2 aqueous solutions gradually increased from 42% on the next day to 86% after 45 days, indicating that E-MoS2 has a great potential to form large aggregates over time. All E MoS2/Cy-PPG solutions with different Cy-PPG concentrations (65-90%) showed greater MoS2 dispersion reliability compared to E-MoS2 solutions, and only a small increase in light penetration after 45 days.

The average thickness of E-MoS2 nanosheets decreased from 5 nm to 2 nm when the Cy-PG concentration increased. The conductivity of spin-coated E-MoS2 films was 50.1 ± 2.3 S/cm after the initial stripping of MoS2 in water, which was much larger than that of pure MoS2. After subsequent grinding, the conductivity of spin-coated monolayer films was as high as 127 ± 3.2 S/cm.

Overall, this newly designed, eco-friendly controlled exfoliation technique provides a simple and ecological approach for producing MoS2 nanocomposites.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com