Technical University of Munich Reduces Waste of Mo-99 Derivate - Tc-99m Production

- Details

- Category: Tungsten's News

- Published on Friday, 08 April 2022 22:24

A study conducted at the research neutron source Heinz Maier-Leibnitz (FRM II) at the Technical University of Munich (TUM) has shown that the radioactive waste generated during the production of Mo-99 product - Technetium-99m (Tc-99m) could be significantly reduced.

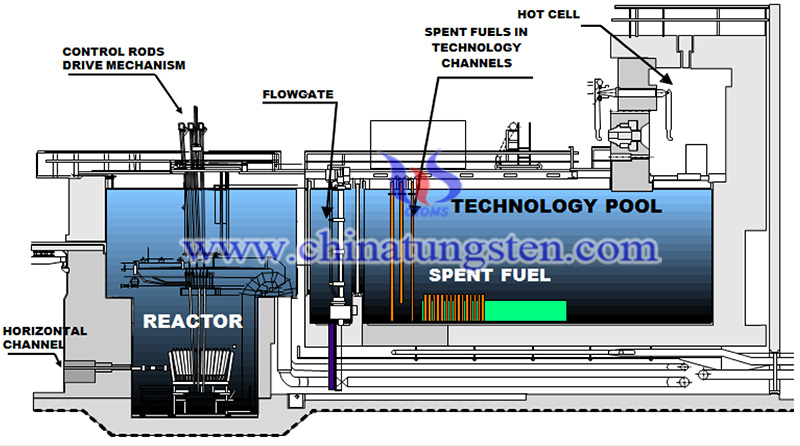

More than 85% of nuclear medicine diagnostic tests use Technetium-99m, and in Germany alone, more than 3 million canisters of Technetium-99m are used each year. Technetium-99m is produced by irradiating uranium plates or targets with a high neutron flux that is actually only available in research reactors. First, uranium-235 produces molybdenum-99, which decays to Tc-99m with a half-life of 66 h. With a half-life of 6 h, the latter is converted to technetium-99, which emits the gamma radiation needed for diagnosis.

Current political efforts are also calling for the replacement of highly enriched uranium (HEU) with low-enriched uranium (LEU) in the medical field. The Mo-99 irradiation facility currently under construction at FRM II is being designed for the LEU target.

"However, this leads to a serious problem: the lower the uranium-235 enrichment of the uranium platelets, the lower the specific yield of molybdenum-99 during irradiation," said Dr. Tobias Chemnitz, instrumentation manager at FRM II's MEDAPP medical irradiation facility.

In order to be able to meet the world's demand for Tc-99m, at least twice as many uranium plates have to be irradiated and processed, depending on the technology used, and this leads to a corresponding increase in the amount of waste.

The irradiated wafers contain only about 0.1% Mo-99, which must be carefully separated from other materials in order to be pure enough for medical applications. There are two common standard processes, based on acidic and alkaline processes. In the alkaline variant, it needs to be treated first with caustic soda.

The remaining product is then separated from the aqueous solution using a complex chemical separation process. If LEU is used instead of HEU targets, the amount of radioactive waste generated doubles to as much as 15,000 liters of aqueous-based moderate radioactive waste per year for the same molybdenum yield. This waste must still be solidified to be suitable for final storage. Thus, the production of molybdenum-99generates 375,000 liters of radioactive waste worldwide each year.

To solve this problem, Chemnitz and his colleague Riane Stene of the Technical University of Munich developed a new method to extract molybdenum-99 without the use of aqueous chemicals, in collaboration with the Fluorine Chemistry Working Group at Philipps University in Marburg, they developed a system to react uranium-molybdenum test flakes with nitrogen trifluoride in a plasma.

These flakes contain the same amount of molybdenum as is present in the irradiated target. They then used a light-controlled reaction to separate the excess uranium from the molybdenum, and the two elements were separated as effectively as a wet chemical separation, but in contrast, without producing any aqueous waste.

"There are currently six large irradiation facilities worldwide that produce molybdenum-99. Four of these research reactors are more than 40 years old, which could lead to unforeseen maintenance and shutdowns. Therefore, we are proud that here at FRM II, together with the Jules-Horowitz reactor in France, we will be able to meet the future demand for Mo-99 in Europe," said Dr. Chemnitz.

TUM has filed a patent for the process. Even though further development work is still needed, the Technical University of Munich researcher believes that in the medium term it will represent a sustainable alternative to existing processes for reducing waste in Tc-99m production.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com