General Motors and MP Materials Partner to Scale Rare Earth Magnets Production in US

- Details

- Category: Tungsten's News

- Published on Tuesday, 21 December 2021 16:20

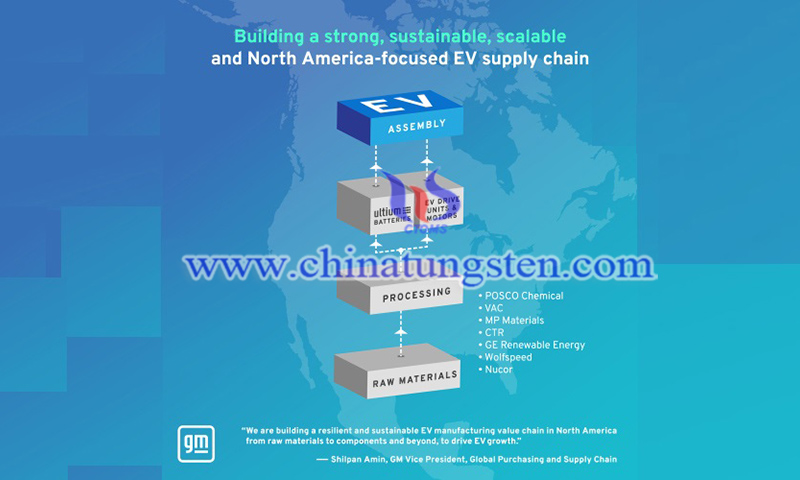

General Motors Corporation (GM) and MP Materials recently announced a strategic partnership to develop a fully integrated US rare earth magnets supply chain. Under the long-term agreement, MP will supply U.S.-sourced and manufactured rare earth materials, alloys, and finished magnets for electric motors used in the GMC HUMMER EV, Cadillac LYRIQ, Chevrolet Silverado EV, and a dozen models using GM's Ultium platform, with production scaling up over time starting in 2023.

Neodymium iron boron (NdFeB) magnets are the key input that enables electric motors to convert electricity into motion. Although the development of permanent magnets began in the United States, there is currently little domestic capacity to produce sintered NdFeB magnets. This strategic collaboration aims to accelerate the restoration of the U.S. rare earth supply chain to a commercial scale, making it highly resilient and environmentally sustainable.

MP Materials owns and operates the Mountain Pass rare earth mine and processing facility in California, the only active, scaled rare earth production site in the United States. Rare earth materials obtained from Mountain Pass will be converted into metals, NdFeB alloys, and magnets at a new production facility announced today by MP, providing an end-to-end US supply chain.

"We are building a resilient and sustainable EV manufacturing value chain in North America, from raw materials to battery manufacturing to electric drive motors and beyond, further accelerating GM's vision to support the mass market for electric vehicles," said Shilpan Amin, vice president of global procurement and supply chain for GM. "Our partnership with MP Materials is another bold step forward that will help ensure we achieve our goal of leading the electric vehicle industry in North America, not just in sales."

"A large-scale restoration of the entire rare earth supply chain in the United States would not be possible without U.S. manufacturers like GM recognizing the strategic consequences and acting with determination," said James Litinsky, chairman and CEO of MP. "We are proud to welcome GM as a foundational automotive customer for our new rare earth magnets facility and to join forces with a company that is fully aligned with our vision to reinvigorate the spirit of American manufacturing."

General Motors and MP Materials have signed a binding terms agreement and expect to enter into a definitive supply agreement in the near term. In addition, the two companies will seek to collaborate from a public policy perspective to seek policies that support the establishment of a secure U.S. rare earth supply chain.

MP's domestic supply chain spanning California and Texas will provide reliable sourcing, supply and sustainability. Mountain Pass is a closed-loop, zero-discharge rare earth production facility that uses a dry tailings process to recover more than one billion liters of water per year.

To optimize efficiency and sustainability, waste generated by MP Materials during the production of rare earth alloys and rare earth magnets will be recycled into the process. General Motors and MP will also explore the potential to further optimize production efficiency and conserve natural resources through new recycling methods based on end-of-life, closed-loop principles.

- Rare Earth Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com