290,000 Tons of Global Molybdenum Output in 2019, China Accounts for Nearly 50%

- Details

- Category: Tungsten's News

- Published on Tuesday, 31 March 2020 20:49

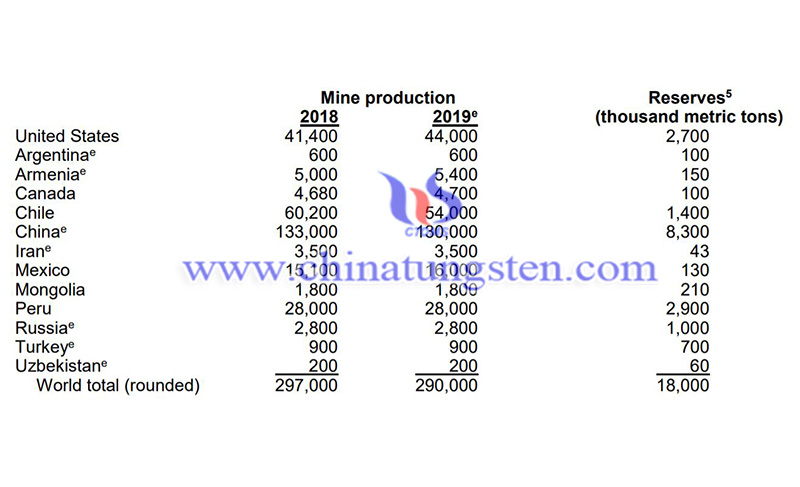

U.S. Geological Survey mineral product summary 2020 data shows that as of the end of 2019, the world's molybdenum reserves were 18 million tons, of which China's reserves were 8.3 million tons, which was the world's largest resource country; followed by Peru, 2.9 million tons; the United States, 2.7 million tons; Chile, 1.4 million tons; Russia, 1 million tons; Turkey, 700,000 tons; Mongolia, 210,000 tons; Armenia, 150,000 tons; Mexico, 130,000 tons; Argentina, 100,000 tons; Canada, 100,000 tons; Uzbekistan, 60,000 tons; and Iran, 43,000 tons.

In 2019, the world's molybdenum output was 290,000 tons, of which China's output was 130,000 tons, accounting for approximately 44.83%, which is the world's largest producer of the metal; followed by Chile, 54,000 tons; the United States, 44,000 tons; Peru, 28,000 tons; Mexico, 16,000 tons; Armenia, 5400 tons; Canada, 4700 tons; Russia, 2800 tons; Iran, 2500 tons; Mongolia, 1800 tons; Turkey, 900 Tons; Argentina, 600 tons; Uzbekistan, 200 tons.

In 2019, US ore production of the metal increased by 7% to 44,000 tons compared with the previous year. In the United States, Mo metal ore was produced as a primary product at two mines, both in Colorado, whereas seven copper mines (four in Arizona and one each in Montana, Nevada, and Utah) recovered molybdenite concentrate as a byproduct. Three roasting plants converted molybdenite concentrate to molybdic oxide, from which intermediate products, such as ferromolybdenum, metal powder, and various chemicals, were produced. Metallurgical applications accounted for about 88% of total US consumption.

Molybdenum is recycled as a component of catalysts, ferrous scrap, and superalloy scrap. Ferrous scrap includes revert scrap, new scrap iron, and old scrap iron. Scrap steel is the residue produced during the steelmaking process. New scrap is generated by steel mill customers and recycled by scrap recyclers and processors. Most of the old waste is molybdenum-containing alloys, which are recycled after the end of their useful life.

The amount of Mo metal recycled as part of new and old steel and other scraps may be as much as 30% of the apparent supply. The United States does not currently have a process for separating recovery and refining secondary molybdenum from alloys. The metal is not recovered separately from steel and superalloys, but the metal content in the recovered alloy is high and the content can be reused. The recycling of molybdenum-bearing scrap will continue to depend on the market for major molybdenum-containing alloy metals such as iron, nickel, and chromium.

From 2015 to 2018, the United States imported ferromolybdenum mainly from Chile, 54%; Republic of Korea, 33%; Canada, 8%; and other, 5%. Mo ores and concentrates: Peru, 53%; Chile, 27%; Canada, 11%; Mexico, 8%; and other, 1%.

Currently, China is the largest producer of the metal. Mo occurs as the principal metal sulfide in large low-grade porphyry molybdenum deposits and as an associated metal sulfide in low-grade porphyry copper deposits. Resources of the metal are adequate to supply world needs for the foreseeable future.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com