Tungsten Worm Weights 1

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 September 2014 08:58

- Written by Sherry

- Hits: 498

Tungsten worm weights, also called tungsten barrel weights in some countries, are known as "Diamond Series" because of they are drilled, beveled and diamond polished to avoid damaging the line.

Tungsten worm weights are feature for cone or bullet shape, which designed to easily slip through weeds and appreciated by bass anglers. The weights have a hole through their center to hold the fishing line. Rigged directly in front of soft-plastic baits such as worms or craws, worm weights can be fixed in place or allowed to slide along the line.

Tungsten worm weights are equipped with nylon inserts to keep your line in top working order and not nicked by the weight edge as is common with other weights.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

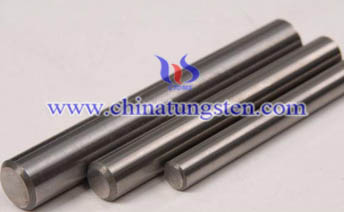

Tungsten Rods for Electrode

- Details

- Category: Tungsten Information

- Published on Tuesday, 23 September 2014 15:31

- Written by jwy

- Hits: 494

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

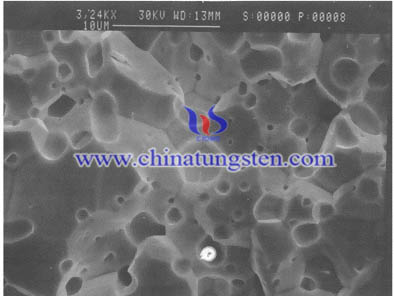

Grain Growth in Tungsten Rod

- Details

- Category: Tungsten Information

- Published on Tuesday, 23 September 2014 15:03

- Written by jwy

- Hits: 528

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

High Purity Tungsten Rod Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 23 September 2014 15:17

- Written by jwy

- Hits: 500

High purity tungsten rod can be used as heat conductor, additive, crankshaft and cylinder barrel of automobile, parts of heat-resistant steel and electrode. High purity tungsten rods are mainly used in guns, rockets, satellites, airplanes and ships.

Chemical components for different purity Tungsten Rods:

| W (>%) | Chemical Content (<%) | |||||||||||

| 99.999 | Fe | Ca | Be | Sn | Al | Ni | Zn | Sb | Pt | K | Ta | Na |

| 0.1 | 0.05 | 0.005 | 0.005 | 0.05 | 0.01 | 0.05 | 0.05 | 0.03 | 0.005 | 0.1 | 0.05 | |

| Cr | Pb | As | Mg | Ti | Bi | Mo | Cd | Cu | Ba | Co | Mn | |

| 0.005 | 0.01 | 0.05 | 0.05 | 0.005 | 0.01 | 0.01 | 0.005 | 0.007 | 0.01 | 0.005 | 0.005 | |

| 99.99 | Fe | Ca | Be | Sn | Al | Ni | Zn | Sb | Pt | K | O | Na |

| 0.1 | 0.45 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.5 | 4 | 0.9 | |

| Cr | Pb | As | Mg | Ti | Bi | Mo | Cd | Cu | Ba | Co | Mn | |

| 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| 99.95 | Fe | Ca | P | Sn | Al | Ni | N | Sb | Si | O | Pb | As |

| 5 | 3 | 1 | 0.1 | 2 | 3 | 3 | 1 | 3 | 3 | 0.1 | 2 | |

| Mg | C | Bi | Mo | |||||||||

| 2 | 5 | 0.1 | 1 | |||||||||

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Microstructure of Rolled and Annealed Tungsten Rod

- Details

- Category: Tungsten Information

- Published on Tuesday, 23 September 2014 14:53

- Written by jwy

- Hits: 494

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com