Tungsten Carbide Rods Types

- Details

- Category: Tungsten Information

- Published on Monday, 22 September 2014 17:22

- Written by jwy

- Hits: 513

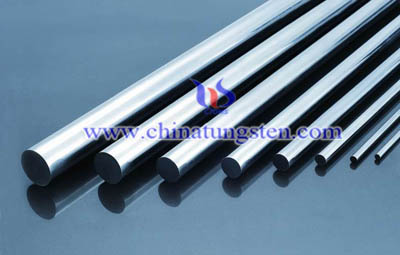

Tungsten carbide as a material compound is in huge demand for its very high strength as well as rigidity. Its comprehensive strength is higher than all existing melted and cast or forged metals and alloys. Its compositions range from two to three times as rigid as steel and four to six times as rigid as cast iron and brass. Young's Modulus is up to 94,8000,000 psi. Tungsten base carbides work well up to about 1000 ℉in oxidizing atmospheres and up to 1500℉ in non-oxidizing atmospheres. Tungsten carbide rods maintain all the features of tungsten carbide with availability of different grades.

Tungsten carbide rod with grade of YF06 is suitable for machining composite materials such as aluminum magnesium alloys, carbon fiber, reinforced plastics and iron based alloys etc.. This product id recommended for making big PCB drills of Φ3.2-6.3 mm, micro drills of Φ0.8-3.2 mm micro milling tools and reamers etc.. These tungsten carbide rods come in various sizes and shapes such as tungsten carbide ungrounded rods,precision ground tungsten rods, precision groung tungsten carbide rods, sintered rods with one straight hole. The material used in manufacturing these products is based on ISO K10, K20, K30 and k40f. Manufacturers also undertake orders of non-standard sizes per the customers' specilifications.

The delivery of all standard pressed rods by the mannufacturers is in inch and metric sizes that are susally made available from their existing stocks. Special grades, sizes and shapes are manufactured to customer specifications and delivered on time. The finished or utility ground rod is available in the length up to 12 inches. For the metal producing industry, the manufacturers also produce tungsten carbide roll rings, flattening rolls, slitter knives, hedge trimmers, scrap chopper blades, saws, guides and other parts suitable for use in tough mill environments.

Manufacturers follow the established standards for all tungsten carbide grades and coontrol checks are performed at each operation. They also check the grain sizes and do chemical analysis ti assure that all products conform to the set standards, Test prices are made to determine physical properties of the products for their hardness, transverse rupture strength and density. They also observe for any fractured and polished surfaces through micrographic test with the test results of each lot being recorded before shipping the product to the final customers or users. Some manufacturerd do provide certification of test resuts when asked by the customers

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com