What Gas Is in Tungsten Iodine Lamp?

- Details

- Category: Tungsten Information

- Published on Monday, 14 August 2023 01:19

- Written by Shuangfeng

- Hits: 1170

There are tungsten vapor, iodine vapor, tungsten iodide gas and inert gas in the iodine tungsten lamp.

Why Does the Tungsten Filament of a Tungsten Iodine Lamp Can Emit Light?

- Details

- Category: Tungsten Information

- Published on Friday, 11 August 2023 17:27

- Written by Shuangfeng

- Hits: 1386

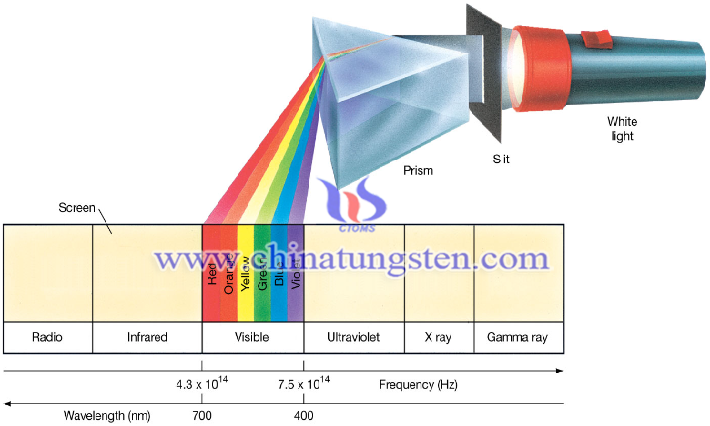

The tungsten filament of a tungsten iodine lamp is a conductor and can radiate visible light. A tungsten iodine lamp is a new type of electric light source, the main components are the internal tungsten filament and the external glass shell. Under the action of electric current, the spiral tungsten filament continuously gathers heat, making the temperature of the filament reach over 2000℃. Microscopically, the tungsten atom's electrons outside the nucleus are excited by heat to a high-energy state, to maintain stability and fall back to a low-energy state, the energy difference in the form of photons released, macroscopically visible luminescence phenomenon.

Read more: Why Does the Tungsten Filament of a Tungsten Iodine Lamp Can Emit Light?

Can Quartz Glass Be Used as the Bulb Shell of Iodine Tungsten Lamp?

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 August 2023 21:30

- Written by Shuangfeng

- Hits: 1243

Quartz glass can be used as bulb shell of iodine tungsten lamp.Iodine tungsten lamp is one of the first choice products in green lighting engineering in China. It has the characteristics of high light efficiency, small volume and energy saving, and is suitable for the design and shape of various lamps and lanterns. It is widely used in lighting field.

Read more: Can Quartz Glass Be Used as the Bulb Shell of Iodine Tungsten Lamp?

How to Handle the Surface Treatment of Iodine Tungsten Lamp?

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 August 2023 22:35

- Written by Shuangfeng

- Hits: 1212

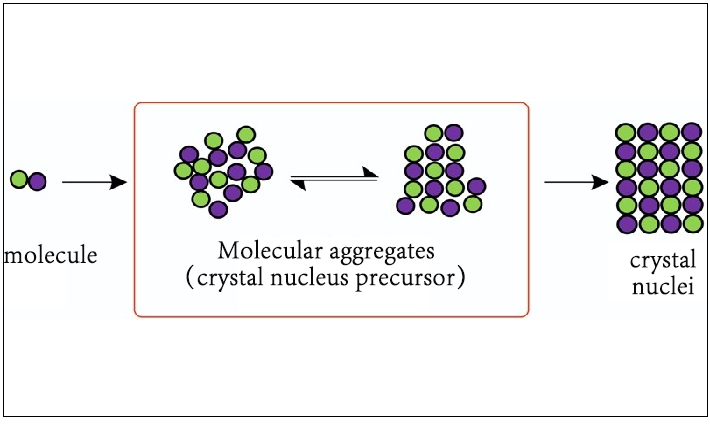

An iodine tungsten lamp is a kind of high-efficiency lighting fixture, which is generally composed of tungsten wire and quartz glass shell. Because of its small size and high internal temperature, the glass shell will undergo a cycle of "melting-cooling-solid reheating" after use. If there is an impurity attached to the bulb shell and the surface treatment is not carried out in time, the atomic arrangement of quartz glass will change at high temperatures, causing the surface to crystallize and lose its transparency. This phenomenon is called devitrification.

Read more: How to Handle the Surface Treatment of Iodine Tungsten Lamp?

Can Ordinary Glass Be Used as a Bulb Shell for Iodine Tungsten Lamp?

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 August 2023 21:10

- Written by Shuangfeng

- Hits: 1135

Ordinary glass cannot be used as a bulb shell for an iodine tungsten lamp. The iodine tungsten lamp is a kind of illumination lamp that uses the principle of halogen-tungsten circulation to fill iodine into the bulb to control the sublimation of the tungsten wire. It has the characteristics of high brightness and long life. It is often used as the light source of cinematography stage factory building square.

Read more: Can Ordinary Glass Be Used as a Bulb Shell for Iodine Tungsten Lamp?

sales@chinatungsten.com

sales@chinatungsten.com