Uses of Tungsten Wire in Audiovisual Projector Lamps

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 15:35

- Written by Zhenghua

- Hits: 117

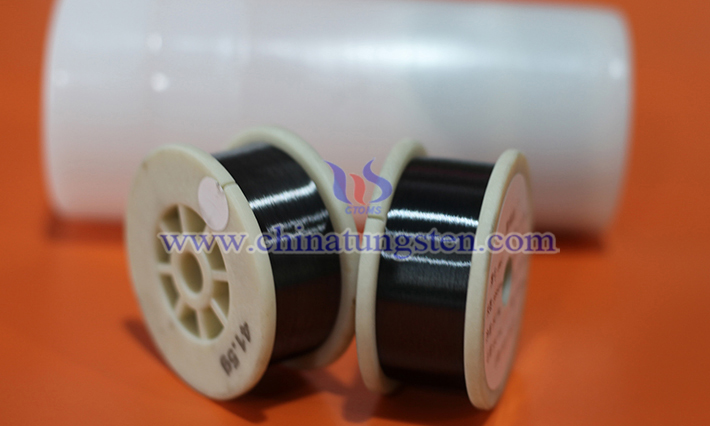

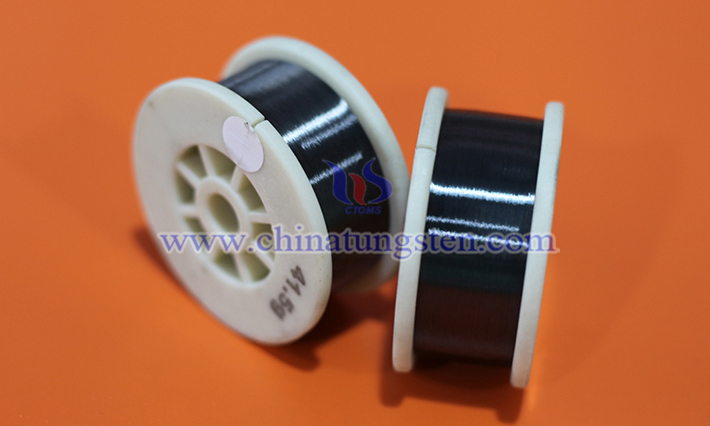

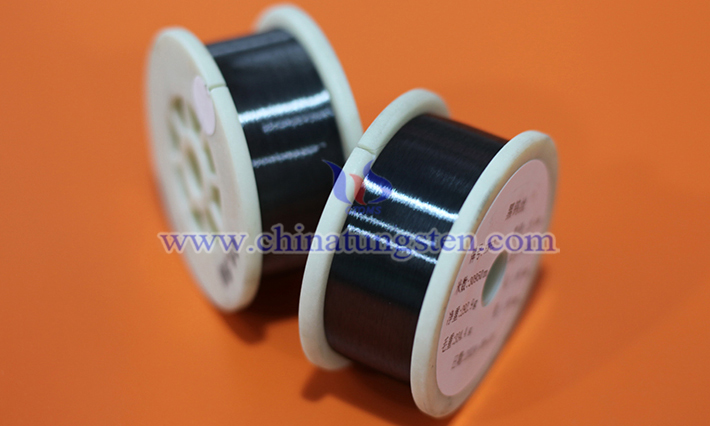

Due to its excellent luminous properties, high melting point, and favorable mechanical properties, tungsten wire is widely used in audiovisual projector lamps and is a key component in ensuring high-quality illumination and stable operation.

Read more: Uses of Tungsten Wire in Audiovisual Projector Lamps

Roles of Tungsten Wire in Projector Filaments

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 15:34

- Written by Zhenghua

- Hits: 111

Tungsten wire serves as the core light-emitting element in projector filaments. Its unique physical and chemical properties, combined with the working principles of projectors, are specifically reflected in the following aspects:

Tungsten wire Applications in Automotive Lighting

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 15:28

- Written by Zhenghua

- Hits: 110

Tungsten wire has long played a crucial role in automotive lighting, particularly in traditional halogen automotive lamps.

Read more: Tungsten wire Applications in Automotive Lighting

Tungsten Wire Applications in Floodlights

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 15:31

- Written by Zhenghua

- Hits: 113

Tungsten wire floodlights (especially halogen tungsten wire lamps) maintain their unique optical properties in film and television production, stage lighting, and professional photography, even as LED technology has become mainstream.

Differences Between Tungsten Disulfide and Tungsten Diselenide

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 11:39

- Written by Xiaoting

- Hits: 110

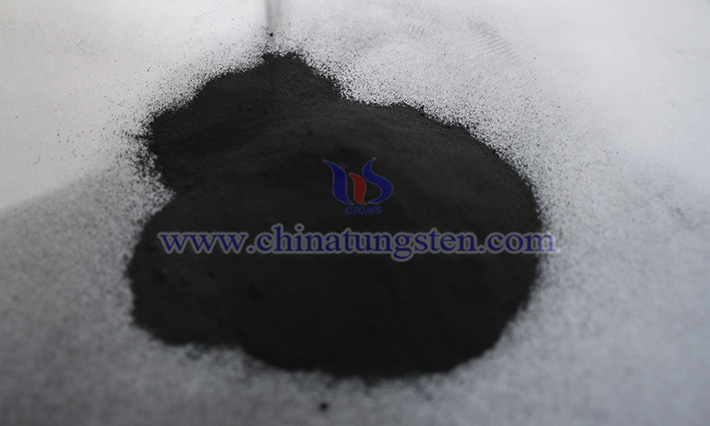

Tungsten disulfide and tungsten diselenide are typical compounds of the rare metal tungsten, both formed by combining the transition metal element tungsten with chalcogen elements (oxygen group elements). Both exhibit excellent physical, chemical, and thermal properties and are widely used in the optoelectronic field. However, there are significant differences between them in terms of specific concepts, properties, and applications. These differences stem from the distinct characteristics of sulfur and selenium, the chalcogen elements involved, which in turn lead to variations in their crystal structures, electronic bandgaps, and chemical stabilities. Such differences further result in their pergent performance in optoelectronic devices, catalytic reactions, and lubrication applications, making each compound suitable for specific scenarios based on its unique attributes.

Read more: Differences Between Tungsten Disulfide and Tungsten Diselenide

sales@chinatungsten.com

sales@chinatungsten.com