The Heating Effect of Tungsten Wire in a Vacuum Furnace

- Details

- Category: Tungsten Information

- Published on Monday, 11 August 2025 18:59

- Written by Zhenghua

- Hits: 13

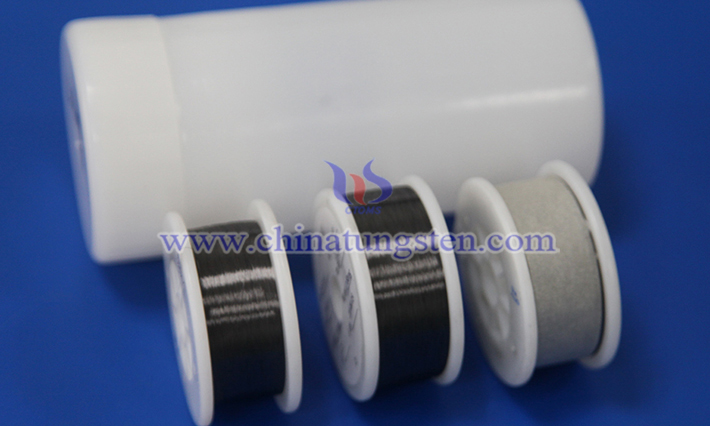

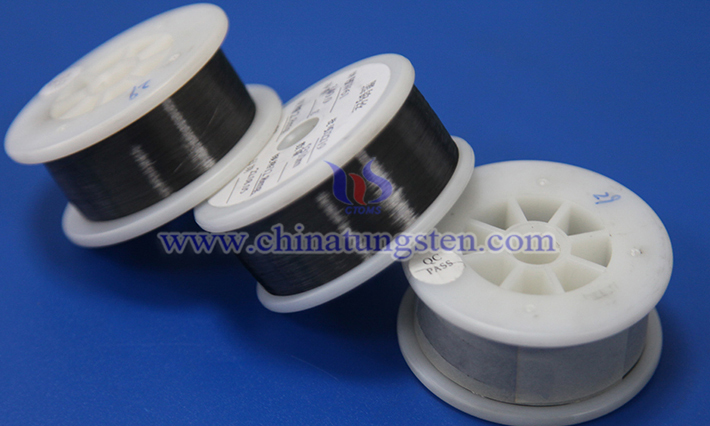

The heating effect of tungsten wire in a vacuum furnace primarily relies on its high melting point, high resistivity, and low vapor pressure. It generates high temperatures through resistive heating and transfers heat through radiation, making it suitable for a variety of high-temperature processes.

1. Characteristics of Tungsten Wire

High Melting Point: Tungsten has the highest melting point of approximately 3422°C among known metals, enabling tungsten wire to operate at extremely high temperatures without melting or deforming.

High Resistivity: Tungsten wire has a high resistivity and generates significant resistive heating (Joule heating) when current passes through it, which is the core principle of its heating effect.

Low Vapor Pressure: At high temperatures, tungsten has an extremely low vapor pressure, reducing the possibility of volatilization or loss in a vacuum environment, making it suitable for long-term use.

Chemical Stability: Tungsten wire is not easily oxidized in a vacuum environment, maintaining stable performance.

2. Heating Principle

Resistance Heating: When current passes through the tungsten wire, electrons collide with tungsten atoms, converting electrical energy into heat energy, heating the tungsten wire to a high temperature. This heat is transferred in the following ways: (1) Radiation: The tungsten wire radiates energy to the surroundings in the form of electromagnetic waves (mainly infrared rays) at high temperatures, heating the objects in the furnace. (2) Conduction (limited): In a vacuum environment, heat conduction is weak, and radiation is the main heat transfer method.

Temperature Control: By adjusting the current, the temperature of the tungsten wire can be precisely controlled, thereby controlling the heating effect in the vacuum furnace.

Advantages of Vacuum Environment: There is no oxygen in the vacuum furnace, and the tungsten wire will not oxidize. It can work stably at high temperatures for a long time, extending its service life.

3. Specific Functions in Vacuum Furnaces

High-Temperature Heating: The tungsten wire can raise the temperature in the furnace to above 2000°C, making it suitable for high-temperature heat treatment, sintering, melting and other processes.

Uniform Heating: By rationally designing the shape (such as spiral or mesh) and distribution of the tungsten wire, a uniform temperature distribution in the furnace can be achieved. Material Processing: Widely used for heat treatment of metals, ceramics, semiconductors, and other materials, such as annealing, sintering, and evaporation coating.

Special Applications: In a vacuum environment, tungsten wire heating can be used in processes such as vacuum evaporation and electron beam evaporation to produce thin films or high-purity materials.

4. Precautions in Practical Applications

Tungsten wire embrittlement: Prolonged high-temperature use may cause grain growth in the tungsten wire, making it brittle and requiring regular inspection and replacement.

Current Control: Precise current control is required to prevent overheating and burnout of the tungsten wire.

Vacuum Requirements: Insufficient vacuum may cause oxidation of the tungsten wire, reducing its lifespan and heating efficiency.

Thermal Efficiency: Since the furnace primarily relies on radiation heat transfer, the furnace design must be optimized to minimize heat loss.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com