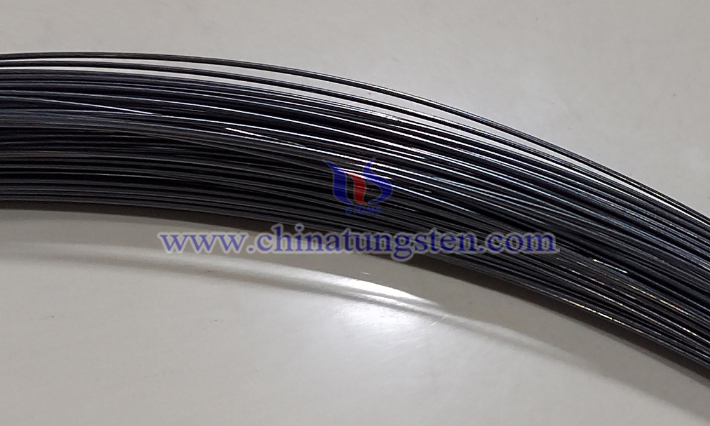

Tungsten Wire as a Component of High-Temperature Industrial Furnaces

- Details

- Category: Tungsten Information

- Published on Monday, 11 August 2025 19:01

Tungsten wire is a key component in high-temperature industrial furnaces due to its excellent high-temperature resistance and electrical resistance.

I. Characteristics of Tungsten Wire

1. High Melting Point: Tungsten has a melting point of 3422°C, the highest of all metals, making it suitable as a heating element in high-temperature industrial furnaces (such as vacuum furnaces, sintering furnaces, and heat treatment furnaces).

2. High-Temperature Strength: Tungsten wire maintains high mechanical strength at high temperatures and is not easily deformed or broken.

3. Oxidation Resistance: Tungsten reacts easily with oxygen at high temperatures and is therefore often used in a vacuum or inert gas environment (such as argon or nitrogen) to prevent oxidation.

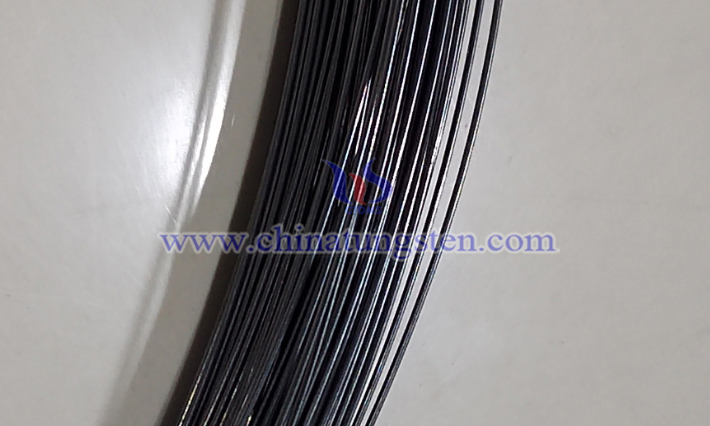

4. Low Thermal Expansion Coefficient: Tungsten has a low thermal expansion coefficient and good thermal stability, making it suitable for long-term high-temperature operation. 5. Good Electrical Conductivity: Tungsten wire has an appropriate resistivity, enabling efficient conversion of electrical energy into heat.

II. Applications in High-Temperature Industrial Furnaces

1. Heating Elements: Tungsten wire is often formed into spiral or mesh structures and used as a resistance heating element in vacuum furnaces, single crystal furnaces, ceramic sintering furnaces, and other applications, providing a stable high-temperature environment (up to 2000°C).

2. Thermocouple Sheaths: Tungsten wire or tungsten-based materials are sometimes used to make thermocouple sheaths to protect measuring equipment at extremely high temperatures.

3. Crucibles and Supports: Tungsten wire can be used to support high-temperature crucibles or as a structural material within high-temperature furnaces.

4. Special Processes: Tungsten wire is a key heating element in processes such as metal powder metallurgy, crystal growth (such as sapphire single crystal growth), and high-temperature annealing.

III. Usage Precautions

1. Environmental Requirements: Tungsten wire will oxidize at high temperatures in oxygen-containing environments and must be used under vacuum or inert gas protection. 2. Brittleness: Tungsten wire may recrystallize after high-temperature use, resulting in increased brittleness. Careful handling is required to avoid mechanical damage.

3. Current Control: The resistance of tungsten wire varies significantly with temperature, requiring precise current control to prevent overheating and burnout.

4. Cost: Tungsten wire is expensive and difficult to process, so cost and performance must be considered comprehensively.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com