Pine Creek Tungsten Mine History (I)

- Details

- Category: Tungsten's News

- Published on Friday, 21 July 2017 17:14

- Hits: 791

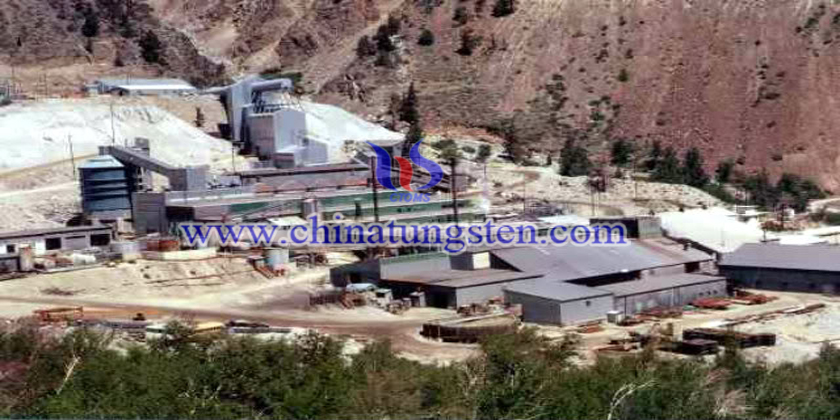

Pine Creek Tungsten Mine locates on the south of Nevada mountain in California, 18 miles northwest from bishop town, altitude is 3300m, is a tungsten mine with centurial history.

Tungsten Price in The Second Half of 2017: Cautiously Optimistic

- Details

- Category: Tungsten's News

- Published on Friday, 21 July 2017 11:02

- Hits: 649

The prices of mainstream tungsten products continued to sustaining steady growth yesterday in China, and the volume is small. In the short term, tungsten concentrate’s tight supply is not easy to improve.

The prices of mainstream tungsten products continued to sustaining steady growth yesterday in China, and the volume is small. In the short term, tungsten concentrate’s tight supply is not easy to improve.

Dysprosium Oxide, Cerium Oxide Price

- Details

- Category: Tungsten's News

- Published on Friday, 21 July 2017 09:08

- Hits: 529

Rare earth prices in China maintain stability. And there is room for improvement in the aftermarket. The national purchasing and storage, limited production due to environmental protection and anti normalization promote the industry’s standardization and scientific development.

Ready Tungsten Market: Lack of Demand

- Details

- Category: Tungsten's News

- Published on Thursday, 20 July 2017 11:28

- Hits: 547

The once increased prices of tungsten products are stable again yesterday in China. Supported by raw material suppliers’ optimistic view of prices, APT market prices continued to rise slightly. Though in the off-season, there is still a ready Chinese tungsten market which lacks of downstream demand.

Lanthanum Oxide, Europium Oxide Price – Jul. 19, 2017

- Details

- Category: Tungsten's News

- Published on Thursday, 20 July 2017 09:58

- Hits: 578

Rare earth prices in China sustaining steady growth, and shares in the rare earth sector also rise rapidly. Particularly, there are many stocks moved up in terms of permanent magnet stocks.

Tungsten Corporation: Negotiated Prices Increased

- Details

- Category: Tungsten's News

- Published on Wednesday, 19 July 2017 14:16

- Hits: 601

The advantage of tight raw material supply took the lead in breaking the market deadlock when the market opened this week. Tungsten products prices in China have increased.

Europium Oxide and Lanthanum Oxide Prices

- Details

- Category: Tungsten's News

- Published on Wednesday, 19 July 2017 10:51

- Hits: 584

With the relationship between supply and demand improved, rare earths prices maintained steady growth. Since 2016, rare earths prices have bottomed out, and prices of main varieties of rare earths in the past year rose by about 10%-90%.

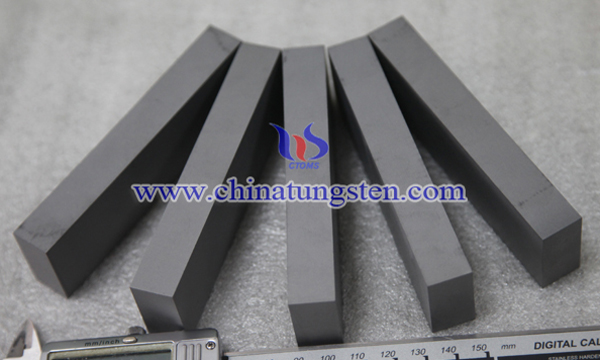

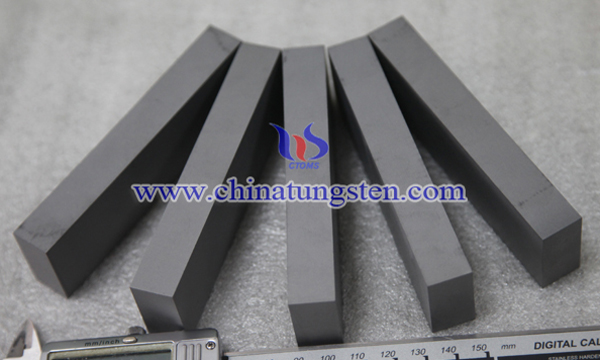

Industry Growth Opportunities In Tungsten Carbide Market Delivered In Latest Report

- Details

- Category: Tungsten's News

- Published on Wednesday, 19 July 2017 09:48

- Hits: 565

The tungsten carbide market report includes definitions, classifications, applications and industry chain structure. This market research report of 84 Pages also provides supply and demand Figures, revenue, development trends, competitive landscape analysis, and key regions distributors analysis, revenue and shares.

Highlights of the tungsten carbide market report include competitive landscape and strategic recommendations, The tungsten carbide market forecast and growth areas for traction bed industry, changing market trends and emerging opportunities, historical shipment and revenue, market analysis by key applications, main manufacturers in market share.

Full-Scale Analysis of tungsten carbide market 2022 include market consumption by Regions., industry chain, demand analysis & market shares. Market drivers and distributor analysis, application market analysis and technology status., research methodology and company profiles, market product analysis, shipment, ASPs, revenue. In Nutshell, the report gives detailed information about U.S tungsten carbide market main manufacturers, company profiles, product analysis, shipment, ASPs, revenue, market shares and contact information are included. For industry chain, upstream raw materials and equipment and downstream demand analysis are also carried out. Finally, U.S and major regions U.S tungsten carbide industry forecast is offered.

Major table of contents mentioned in the report include overview of tungsten carbide market, U.S shipment, ASP, gross and revenue analysis by 2022, application market analysis, main regions analysis, U.S shipment, ASP, gross and revenue analysis of tungsten carbide by manufacturers, technology status and plants analysis of U.S market, key manufacturers analysis of market, forecast 2017-2022, research method of tungsten carbide market analysis & forecast report, conclusion of the tungsten carbide market report 2017-2022 and continued.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Latest Prices of Tungsten Concentrate and Ammonium Paratungstate

- Details

- Category: Tungsten's News

- Published on Tuesday, 18 July 2017 10:36

- Hits: 609

Tungsten market on July 17, 2017: the latest prices of tungsten concentrate, ammonium paratungstate and tungsten carbide powder increase across the board. The supply of raw material is still tight. Raw material plants insist on a conservative selling way.

Latest Prices of Europium Oxide and Terbium Oxide

- Details

- Category: Tungsten's News

- Published on Tuesday, 18 July 2017 09:48

- Hits: 574

As the second batch of total production control plan for rare earth production issued, prices of rare earths sustain steady growth in China.

sales@chinatungsten.com

sales@chinatungsten.com