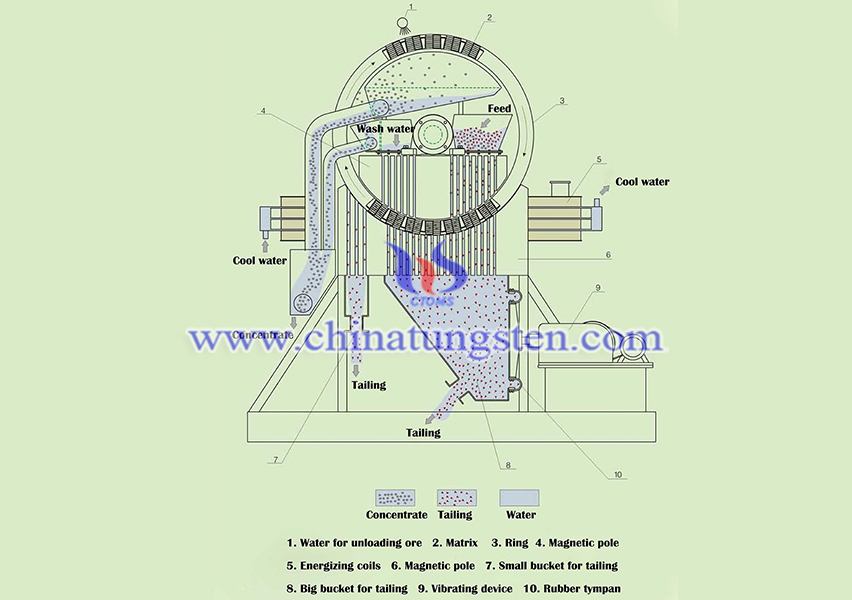

Vertical Ring Type Strong Magnetic Separator

- Details

- Category: Tungsten Information

- Published on Friday, 21 July 2017 14:51

The invention of magnetic separator took a technological change for the selection of tungsten concentrate. Since "Jones" flat ring type strong magnetic separator was born in 60s, the magnetic separator became the centre of attention due to its advanced beneficiation design concept.

However, people soon found that because of the design defects, flat ring type magnetic separator is easy to block ore, and must be cleaned up every two or three day. and offset. Merits offset faults, the beneficiation to whole efficiency of the process is of little importance, magnetic separator was so called useless beautiful decoration.

In 1977, through technical research, Chinese scientific and technical personnel improved the structure model of Jones strong magnetic separator, inventing vertical ring wet magnetic separator, of which the structure solve the problem that Jones strong magnetic separator is easy to be blocked.

There are two types of vertical ring type strong magnetic separator: single loop machine and double loop machine. Double loop machine is used more widely as it has two rings which can carry out the same procedure or respectively carry out the roughing-sweeping, or roughing- concentration, featured two kinds of sorting process. Flexible and economical, the light small machine has a lot of advantages such as low gravity, stable operation, less wearing parts and higher operation rate. At the same time, because the problem of medium clogging has been well solved, vertical ring type strong magnetic separator with low requirement for ore feeding can reduce the thickness, slag removal and high pressure water washing facilities, simplifying the beneficiation process and making it more convenient to manage production.

In the mineral processing, vertical ring type strong magnetic separator chooses two sorting rings to respectively vertical rotate around the horizontal spindle, and of which the lower parts pass through the magnetic lines of the separation area and form into two horizontal magnetic fields. The ball medium in the sorting chamber of magnetic field generates a strong magnetic force around the contact point between the spheres, influenced by magnetism. And it is time to feed the prepared pulp into the machine feeder to get buffer. The ore particles in the ore slurry, be evenly fed into the separation zone, getting ample contact with the spherical dielectric surface. Weakly magnetic particles adhered to the surface of the dielectric ring are lifted to the top of a very weak magnetic field with the sing turning. Finally, the particles are poured into the concentrate trough by high pressure water. Freed from magnetic force, non-magnetic mineral particles enter into the tailings tank through the medium ball gap.

Vertical ring type strong magnetic separator regarded as a significant breakthrough of flat ring type magnetic separator is the technological crystallization of scientific research workers in China. It is vertical ring type strong magnetic separator that helps magnetic separation equipment to get rid of the “vase” jokes and began to be widely used in the socialist industrial construction and get a faster accumulation of technology. Currently, the separator has been upgraded several times, and its function is improved. Enjoying the convenience of the magnetic separation equipment, we should never forget the contribution made by older generation of scientists.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com