How to Obtain Tungsten Diiodide by Indirect Preparation?

- Details

- Category: Tungsten Information

- Published on Thursday, 29 June 2023 17:46

The indirect preparation method of tungsten diiodide does not aim at obtaining the product directly but is a method of preparing other tungsten iodide compounds before preparing the final product. The indirect preparation method develops based on the direct preparation method and chooses tungsten iodide compounds that are easier to prepare relative to tungsten diiodides, such as tungsten triiodide (WI3) and tetraiodide (WI4), as intermediate products, to reduce the requirements and uncontrollable factors of the reaction conditions and to improve the yield of tungsten diiodide.

Preparation of intermediate products

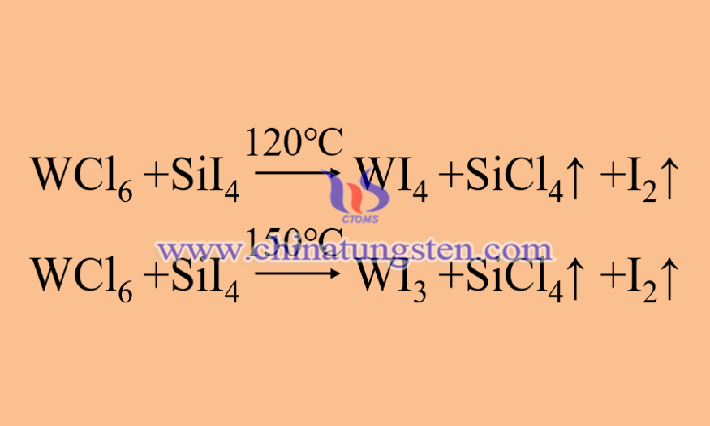

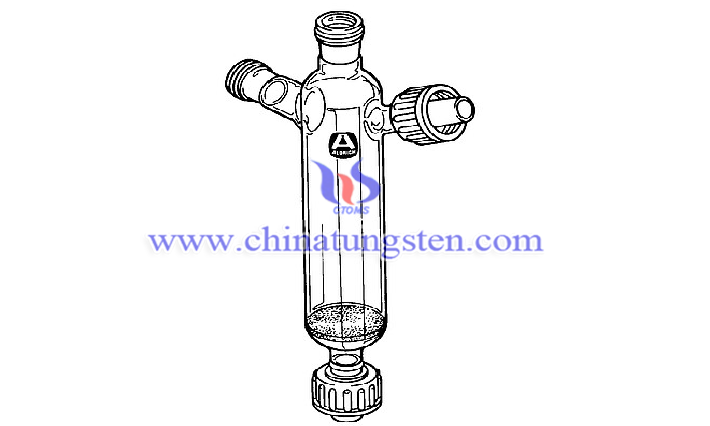

The reaction for the preparation of tetraiodotungsten firstly grinds and mixes tungsten hexachloride (WCl6) with silicon chloride (SiCl4) in a Schlenk tube with two valves, and the reaction is set to a temperature of 120°C. After 16 hours, the Schlenk tube is removed from the oven, at which time the tube still maintains a certain degree of heat, such that the heat ensures that iodine monomers with low sublimation temperatures are in the gaseous state and do not mix with the product. To further extract the intermediate product tetraiodotungsten iodide, it is necessary to remove the residual silicon chloride, remove impurities in the Schlenk tube passed in argon (Ar) as a protective gas, and the introduction of deionized water, at this time the reaction occurs SiCl4 + 4H2O = 4HCl↑ + H4SiO4↓. Due to the temperature in the reaction tube, the product of the original silicic acid (H4SiO4) will be further water loss to get milky white silicic acid (H2SiO3): H4SiO4 = H2SiO3↓+ H2O. remove the residual iodine and silica chloride, you can get the black crystalline powder WI4.

Similar to the principle of generation of tetraiodotungsten, the preparation of tetraiodotungsten triiodide only requires the adjustment of the reaction temperature to 150°C to obtain a black crystalline WI3 powder. These two compounds have been successfully used as starting materials for the preparation of tungsten diiodide.

Conversion of intermediates to tungsten diiodide

The second step of the indirect preparation method is the conversion of the obtained tungsten triiodide and tetraiodide to tungsten diiodide. Since tungsten iodide series compounds decompose under heating conditions, the final product tungsten diiodide can be obtained by heating. Compared to the direct preparation method, indirect preparation is more likely to lead to mass production.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com