Sensitivity and Selectivity Effects of Tungsten Oxide Nanostructures on Pollution Gases

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 March 2022 15:24

Recently, researchers from Jiujiang University and the University of Puerto Rico, USA, conducted a study on the sensitivity and selective effect of tungsten oxide nanostructures on pollution gases. The study titled “Effect of Tungsten Oxide Nanostructures on Sensitivity and Selectivity of Pollution Gases” has been published in the journal Sensors on 26 Aug. 2020. The study was carried out by Fenghui et al.

Gas sensing technology has been widely used in environmental, industrial and medical applications. Sensitive and reliable materials capable of detecting small amounts of hazardous contaminants in the air have been and remain a major challenge. Various metal oxide semiconductors (MOS), the traditional chemical gas sensing materials for resistive gas sensors, have been increasingly investigated because of their simplicity of operation, lightweight, high sensitivity, and low cost.

Among these oxides, tungsten oxide thin films happen to be one of the promising candidates for sensing pollution gases. As a result, a variety of various tungsten oxide semiconductor synthesis techniques have emerged in recent years, including electron beam evaporation, thermal or anodic oxidation, electrochemical deposition, chemical vapor deposition (CVD), sputtering, pulsed laser deposition, sol-gel, and screen-printed thick films based on ultrafine powders.

So far, various crystalline structures and morphologies of tungsten oxides have been fabricated by different synthesis techniques. Tungsten oxide-based gas sensors are used to measure H2, NO2, NH3, NO, H2S, CO, and organic gases such as acetone, methanol, ethanol, and formaldehyde.

Compared with simple tungsten trioxide (WO3) materials, the sensing performance is significantly enhanced by doping with other elements, functionalization with precious metal nanoparticles, or heterojunctions formed with other semiconductors.

Since they were first reported as ammonia sensors in 2000, pure tungsten trioxide-based gas sensors have made a big difference in NH3 leak detection for indoor and outdoor air quality monitoring. However, these sensors typically operate at high temperatures of 150 to 500°C, which complicates design requirements for temperature monitoring and control as well as environmental safety.

Material morphology and crystal structure play a fundamental role in determining sensing performance, as interactions occur mainly at surfaces and boundaries. There is a strong need for a fast, low-cost, and environmentally friendly method of device prototyping in order to optimize process parameters in a controlled way and to explore the relationship between characteristic morphology and sensing performance.

This study reports on a simple no-annealing post-hot filament CVD method to prepare tungsten oxide samples, where the tungsten oxide is grown by direct thermal evaporation of tungsten filaments under moderate vacuum.

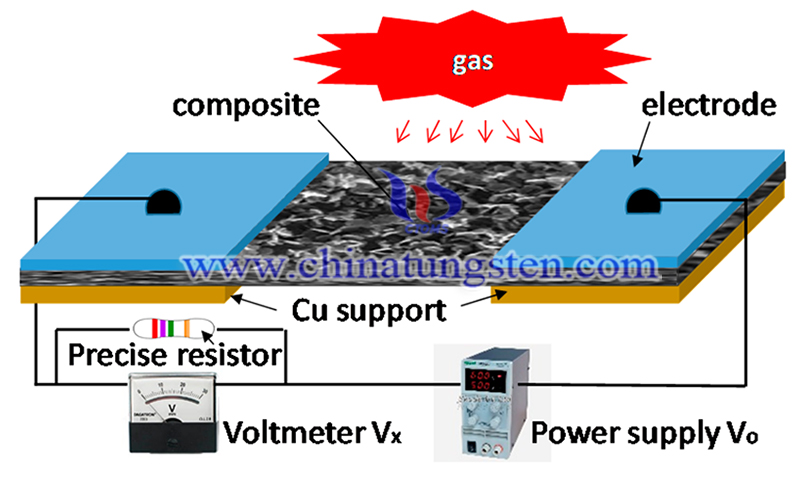

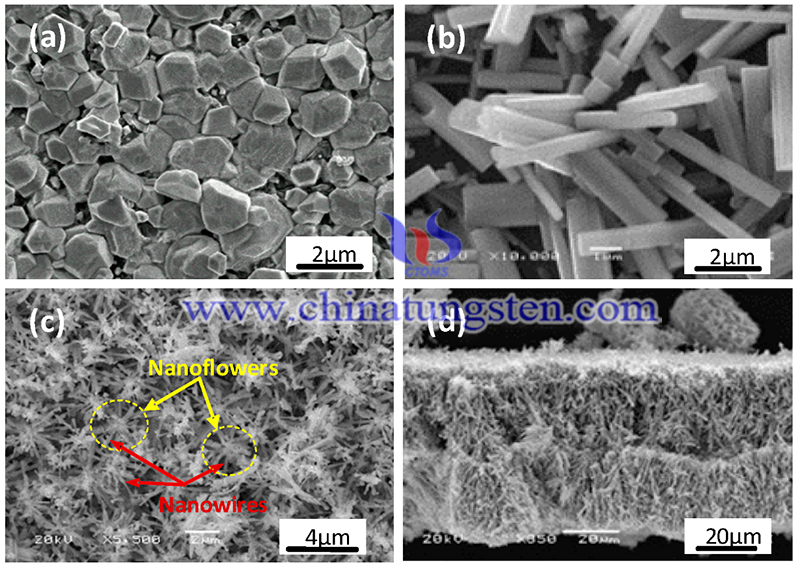

Then, the evolution of the material composition, crystal structure, and surface morphology at different substrate temperatures was investigated using scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), Raman spectroscopy, and X-ray diffraction (XRD) techniques. Gas sensing properties based on the synthesized materials are systematically investigated and compared with their pure counterparts. Finally, a low-cost, high-performance gas sensor operating at room temperature for monitoring air pollutants such as NH3, CO, and CH4 is demonstrated.

In this work, tungsten oxide composites were synthesized using a simple hot-wire CVD technique, with the tungsten wire itself serving as a precursor to tungsten oxide without the use of any catalyst or other tungsten-containing compound precursors.

Controllable compositions and morphologies, including NPs, NRs, and NFs, have been obtained by varying the substrate temperature at relatively high deposition rates. Based on these grown tungsten oxide nanostructures, simple, low-cost gas-sensing prototypes have been designed, fabricated, and tested.

The NF-based gas sensor offers the best performance, followed by the NR-based device and finally the NP device. When operated at room temperature, NF-based gas sensors have the additional advantage of good repeatability and a stable baseline, in addition to high sensitivity and fast response time.

In conclusion, the results of this study show that by fine-tuning the processing parameters, such as the oxygen content in the vacuum chamber, the temperature of the substrate in other forms, such as nanotubes, and the thermal annealing process can be further used to optimize the performance of the sensor. Furthermore, this approach can be modified or doped with other elements, or functionalized with precious metal particles, etc., to further optimize the material properties for sensing different target pollution gases.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com