CeO2–WO3 Catalysts Prepared for Selective Catalytic Reduction of NOx

- Details

- Category: Tungsten Information

- Published on Friday, 10 September 2021 01:08

Nitrogen oxides (NOx) emitted by fossil fuel combustion are one of the main air pollutants, posing a serious threat to the ecological environment and human health. To cope with huge environmental pressure and strict emission targets, NH3 selective catalytic reduction of NOx (NH3-SCR) is still the mainstream NOx control technology.

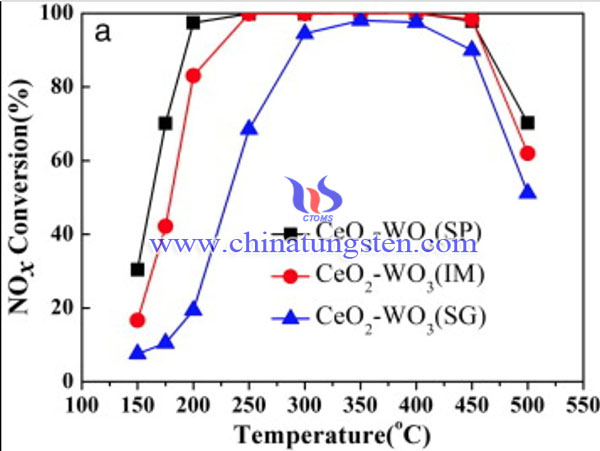

The cerium-tungsten oxide (CeO2-WO3) catalyst is prepared by three methods: one-step sol-gel (SG), impregnation (IM) and solid processing (SP). The main purpose of this study is to determine the best method for preparing CeO2-WO3 catalyst with high NH3-SCR catalytic activity. CeO2-WO3 catalysts have been prepared by different methods for selective catalytic reduction of NOx. The results show that the catalysts prepared by solid treatment (SP) and impregnation (IM) show better SCR activity than those prepared by sol-gel (SG) . ) The method is at 175–500 °C.

Single-step sol-gel method

Ammonium paratungstate is dissolved in the oxalic acid solution, and then (NH4)2Ce(NO3)6 and citric acid are added to the solution under stirring. Use dilute nitric acid (0.1 mol/L) to adjust the pH of the solution to 1.0. In the following steps, the sol is slowly evaporated at 60°C to obtain a transparent colloidal solution, which is then dried at 120°C for 10 hours and calcined in air at 500°C for 4 hours. Finally, the catalyst was obtained and labeled as CeO2-WO3(SG).

Dipping method

Ammonium paratungstate was dissolved in oxalic acid solution, CeO2 was added, stirred at 60°C for 1 hour, ultrasonically treated for 2 hours, dried at 110°C overnight, and calcined in air at 500°C for 4 hours. Finally, the catalyst was obtained and labeled as CeO2-WO3(IM).

Solid process

Cerium nitrate hexahydrate and ammonium paratungstate were first ground in an agate mortar, pulverized in a ball mill for 3 hours, and then calcined in air at 500 ℃ for 4 hours. Then the catalyst was obtained and labeled as CeO2-WO3(SP).

In this work, before characterization, all prepared catalysts were crushed and sieved to 40-60 mesh. The weight ratio of CeO2/WO3 in the sample is 3:2.

In conclusion, CeO2-WO3 catalyst was prepared by different methods for selective catalytic reduction of NOx. The results showed that the catalyst prepared by solid treatment (SP) and impregnation (IM) showed better SCR activity than the catalyst prepared by sol. . -Gel (SG) method, temperature is 175–500 °C. The excellent activity can be attributed to the larger surface area, higher Ce and Ce3 + surface concentration, enhanced NO oxidation ability and more surface acidic sites.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com