Ammonium Metatungstate Applied in Palm Oil Hydrogenation for Biodiesel

- Details

- Category: Tungsten Information

- Published on Sunday, 12 September 2021 11:31

The reduction of fossil fuel sources, environmental pollution caused by engine fuel combustion, and concerns about energy supply have prompted researchers to look for renewable energy sources. Biodiesel has a high flash point (>130 °C), octane number and high combustion yield, as well as appropriate density and viscosity, excellent lubricants, and free sulfur and aromatic compounds. These characteristics have been applied to this engine without any modification and warm-up.

Biodiesel is synthesized by transesterifying triglyceride oil (such as non-edible or edible vegetable oil) with alcohol using a suitable catalyst, which produces fatty acid alkyl groups and glycerin. Therefore, most animal fats and vegetable oils are sources of human feed, and it is unreasonable to use them for biodiesel production.

The focus of this study is to clarify the influence of active metals and support materials on the activity and selectivity of palm oil deoxygenation catalysts. Ammonium metatungstate has been used as a palm oil hydrogenation catalyst to produce biodiesel. Biodiesel shows some interesting characteristics, such as higher oxidation stability, higher cetane number (66) and acceptable coldness. Flow (- 5 °C) characteristics. The production method of the catalyst is as follows:

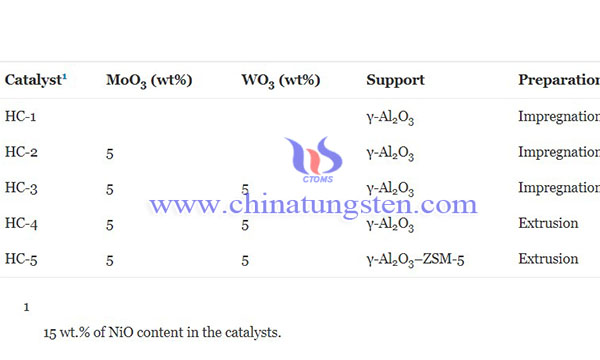

Different products with different ratio was produced as picture. Pretreat the carrier in an oven at 120°C for 2 hours and impregnated with aqueous solutions of nickel nitrate, ammonium molybdate and ammonium metatungstate. The molar ratio of Ni/Mo/W is hydrated at 60 °C for 6 hours. Ultrasonic vibration with a frequency of 50 kHz is applied during the dipping process. Then the Ni, Mo and W precursors were widely dispersed on the pretreated γ-Al2O3 support. The impregnated precursor was dried overnight at 120°C. The carrier was then calcined in the atmosphere at 300°C for 1 hour (heating rate, 5°C/min). After that, it is calcined for another 5 hours at 450°C. Subsequently, a natural cooling process is performed to obtain the oxidation state of the catalyst. The catalysts HC-4 and HC-5 are produced by extrusion method. The main raw material of the HC-4 carrier is a mixture of pseudo-boehmite powder, 5wt.% Sesbania powder, 3wt.% polyvinyl alcohol (polymerization degree 200) and 10wt.% HNO3 aqueous solution. Add 15wt.% ZSM-5 molecular sieve as the carrier material to the catalyst HC-5. The carrier material is thoroughly mixed with a known concentration of active metal salt aqueous solution, kneaded into a dough, and then extruded into a dough. The subsequent drying and calcination steps are the same as the impregnation method.

In conclusion, ammonium metatungstate has been used in producing catalyst in palm oil hydrogenation for biodiesel, the biodiesel shows some interesting properties, such as higher oxidation stability, higher cetane number (66) and acceptable cold flow (- 5 °C) Characteristics. In addition, the alumina/ZSM-5 supported trimetallic catalyst (5 wt.% Ni–5 wt.% Mo–15 wt.% W/85 wt.% γ-Al2O3–15 wt.% ZSM-5) is confirmed It is the best catalyst. The presence of ZSM-5 in the support strongly affects the acidity of the catalyst. It is found that acidity plays an important role in the activity, selectivity and stability of the catalyst. Adding 15 wt.% ZSM-5 catalyst Ni-Mo-W to the γ-Al2O3 carrier produced a diesel yield of 91 wt.%. Under the optimal reaction conditions, the yield of linear n-C15-n-C18 alkanes is 82.9 wt.% (based on carbon). The optimized hydrogenation parameters are: reaction temperature, 360°C; PH2 = 5 MPa, LHSV = 1.0 h−1 and H2/oil volume ratio = 1000.

- AMT Manufacturer & Supplier, Chinatungsten Online: ammonium-metatungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com