Properties of Tungsten Heavy Metal Foil

- Details

- Category: Tungsten Information

- Published on Sunday, 04 January 2015 09:22

- Hits: 302

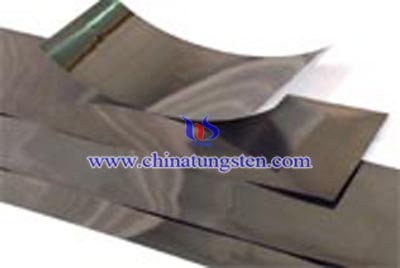

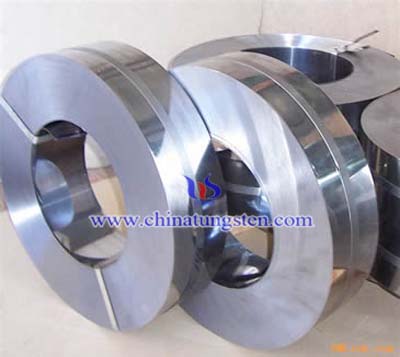

Tungsten heavy metal foil and tungsten strip is extremely heat-proof and heat-resistant.

It has small thermal expansion coefficient, high resistance to thermal creep, good thermal conductivity and high electron emission coefficient. Tungsten heavy metal foil is very solid; it has very high tensile modulus and compression.

It is resistant to corrosion, the action of alkalis and acids, including concentrated hydrochloric, sulfuric and nitric acids, aqua regia, which makes tungsten foil suitable in various fields use.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Pure Tungsten Heavy Metal Foil

- Details

- Category: Tungsten Information

- Published on Wednesday, 31 December 2014 08:44

- Hits: 291

Tungsten heavy metal foil is a product of rolled tungsten - a very thin sheet 0.03 - 0.09 mm in thick. Standard thickness of tungsten heavy metal foil is from 0.00029 "to 0.0035".

According to the requirement of tungsten metal foil, our company can provide excellently-qualified products.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Applications of Pure Tungsten Heavy Metal Rod

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 December 2014 08:52

- Hits: 298

Because of the special properties of tungsten, these rods and bars have many applications.Pure tungsten heavy metal rod/bar can be widely used in electrode, the gate pole in electronic tube, side rod, lead-lines, frame, gas lamp electrodes, high-power incandescent filament, the filament in electronic tube and cathode in launch tube, cylinder barrel of advanced automobile etc.

|

PROPERTIES PHYSICAL OF TUNGSTEN HEAVY METAL ROD & BAR |

|

|

Density |

19.17 g/cm3 |

|

Melting Point |

3410oC |

|

Electrical Conductivity |

31% IACS |

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Pure Tungsten Heavy Metal Rod

- Details

- Category: Tungsten Information

- Published on Monday, 29 December 2014 09:22

- Hits: 279

Pure tungsten heavy metal rod & bar stock are manufactured from high purity tungsten powder.

Tungsten metal rod/bar owns the color of silver.Pure tungsten heavy metal rod/bar can be classified into two types. One kind is finished rod and the other is semi-finished thick rod used to stretch for making tungsten wire and other shape of products.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Carbide Ball Contradictory Characteristics

- Details

- Category: Tungsten Information

- Published on Friday, 26 December 2014 10:09

- Hits: 285

Tungsten carbide ball is typical of brittle products. Traditional tungsten carbide ball is made of a traditional uniform carbide (convention a homogeneous cemented carbide, CHCC) material, a uniform composition and organization of its parts, the entire alloy is homogeneous, with the consistency of its performance. The main component of the cemented carbide comprising a hard phase and a variety of binder phase, the hard phase (e.g. WC phase, solid solution phase) from the hardness and wear resistance of tungsten carbide ball important role, relative tungsten carbide ball bonding have an important impact toughness.

In general, increasing the WC grain size or increase of Co content, can increase the thickness of the binder phase of cemented carbide, cemented carbide can be improved ductility. Carbide good plasticity, deformation may be due to local stress concentration and relaxation; plasticity carbide poor, due to stress relaxation caused by crack initiation and propagation, resulting alloy fragmentation. Therefore, the traditional approach is to improve the content of Co cemented carbide and WC grain size increases as the direction of improving the toughness of tungsten carbide ball. But this makes the hardness and wear resistance while also declined; on the contrary, the hardness and wear resistance can be improved, but at the expense of flexural strength and impact toughness. Therefore, between the tungsten carbide ball material hardness and toughness sharp contradiction exists.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Ball for Pen Surface Condition

- Details

- Category: Tungsten Information

- Published on Friday, 26 December 2014 10:02

- Hits: 293

Tungsten carbide ball has high hardness, wear resistance, corrosion resistance, can replace all the steel ball products in harsh environment. Tungsten carbide ball for pen is often used in producing ballpoint pen. Furthermore its surface condition has an important impact on the writing performance.

Describe the surface condition of the tungsten carbide ball for pen has two aspects, one is the surface roughness, and second, the ball surface and pore size distribution. Any type of tungsten carbide ball for pens to achieve good writing requirements, must have a low surface roughness and uniform fine pores. And throughout the writing process, tungsten carbide ball for pen is relatively stable characteristics can be maintained for a long time, and change little. When such writing can effectively reduce wear between the ball and the ball seat, capillary action through the porous ink is slowly taken out continuously while the excess ink back to the ball seat body, to ensure the stability and excellent writing property.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The introduction of Tungsten Heavy Metal

- Details

- Category: Tungsten Information

- Published on Friday, 26 December 2014 08:46

- Hits: 290

In tungsten's raw form, it is a hard steel-gray metal that is often brittle and hard to work. If made very pure, tungsten retains its hardness (which exceeds that of many steels), and becomes malleable enough that it can be worked easily.

Tungsten heavy metal has the highest melting point and the lowest vapor pressure among all the metals, which makes it a preferred candidate for use as a high performance material in a variety of high temperature products and processes.

Tungsten heavy metal is resistant to corrosion when the humidity is below 60%. However, it must be protected at elevated temperatures. Tungsten heavy metal can oxidize in the presence of oxidizing gases at temperatures above 250°C. Despite this vulnerability, molten glass, nitrogen, inert gases, molten metals and ceramic oxides only slightly affect it.

Widely and extensively used in lighting industry, electronics, military equipment, nuclear, mechanical manufacturing, aircraft components, medical shields, and sports equipment. Tungsten Heavy metal has excellent radiation resistance, electric and thermal conductivities, corrosion resistance with high density (16.5-18.5 g/cm3) and good mechanical strength. Tungsten heavy metal also has small coefficient of expansion and large elastic modulus.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Carbide Ball Material Production - Forming Agent

- Details

- Category: Tungsten Information

- Published on Thursday, 25 December 2014 10:01

- Hits: 304

Paraffin wax and rubber are most widely used in the tungsten carbide ball material production process of forming agent, but because of poor formability paraffin and tungsten carbide ball after a serious increase carbon rubber sintering, people are trying to find a new shape agent to replace the two polymers, hopes that the new wax forming agent both "clean" and rubber excellent formability characteristics, which can improve the tungsten carbide ball hardness and toughness .

Recently, the development of new carbide-forming agents there are two points: first, the "class paraffin" type, this forming agent to maintain the advantages of paraffin and improve its formability on this basis, so that it can improve the tungsten carbide ball properties, such as: the development of a low-melting wax, paraffin wax modification, paraffin wax and beeswax, ozokerite and polymer combination and the like. The second is "rubber" type, the purpose of this is to reduce its forming agent increases the amount of carbon on the basis of merit to keep the rubber, thus ensuring tungsten carbide ball hardness and toughness, mainly PVA, PS, SBS, SBP, SIS and so on.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Ball Types

- Details

- Category: Tungsten Information

- Published on Thursday, 25 December 2014 09:58

- Hits: 255

Tungsten carbide ball has high hardness, wear resistance, corrosion resistance, can replace all the steel ball products in harsh environment,. According carbide components, tungsten carbide ball can be divided into five categories:

1. Tungsten carbide balls have most varieties, the largest output, and the most widely used.

2. Titanium carbide ball including TIC-Mo-Ni, TIC-WC-TaC (NbC) -Mo-Ni series. They have high hardness, is mainly used for finishing of steel and super finishing.

3. The coated cemented carbide ball which is deposited a layer of titanium carbide, titanium nitride, or a composite of both the oxide and the like on the first type of carbide blade surface.

4. Steel base carbide ball is made of steel or tungsten carbide chin as hard phase, which is characterized by heat treatment can be carried out, in the annealed condition, can be cutting, easy preparation various shapes of complex products.

5. Other carbide ball including chromium carbide based cemented carbide ball, carbo-nitride carbide ball, Carbonation Chin alumina carbide ball, etc., they have different characteristics, and is under development.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

History of Tungsten Heavy Metal

- Details

- Category: Tungsten Information

- Published on Thursday, 25 December 2014 09:30

- Hits: 276

In 1781, Carl Wilhelm Scheele discovered that a new acid, tungstic acid, could be made from scheelite (at the time named tungsten). Scheele and Torbern Bergman suggested that it might be possible to obtain a new metal by reducing this acid. In 1783, José and Fausto Elhuyar found an acid made from wolframite that was identical to tungstic acid. Later that year, in Spain, the brothers succeeded in isolating tungsten by reduction of this acid with charcoal, and they are credited with the discovery of the element.

In World War II, tungsten played a significant role in background political dealings. Portugal, as the main European source of the element, was put under pressure from both sides, because of its deposits of wolframite ore at Panasqueira. Tungsten's resistance to high temperatures and its strengthening of alloys made it an important raw material for the arms industry.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com