Carbide Drilling Tools

- Details

- Category: Tungsten Information

- Published on Thursday, 07 May 2015 11:56

- Hits: 260

Carbides drilling tools are extremely hard, and can drill virtually all materials while holding an edge longer than other bits. The material is expensive and much more brittle than steels; consequently they are mainly used for drill bit tips, small pieces of hard material fixed or brazed onto the tip of a bit made of less hard metal. However, it is becoming common in job shops to use solid carbide bits. In very small sizes it is difficult to fit carbide tips; in some industries, most notably PCB manufacturing, requiring many holes with diameters less than 1 mm, solid carbide bits are used.

A method of making drilling inserts by mixing nodules of pre-blended, un-sintered metal carbide/binder composites having certain desirable characteristics such as a very high hardness, oxidation resistance or gall resistance, and dispersing these nodules into other pre-blended, un-sintered and pelletized metal carbide/binder compositions having other desirable characteristics such as high toughness, corrosion resistance, or other property. The dispersion of the first composite into the second composite occurs prior to pressing and sintering of the mixture. In this manner, the integrity of the separate grades is maintained, while the properties of the new composite are enhanced.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cemented Carbide Rock Drill

- Details

- Category: Tungsten Information

- Published on Thursday, 07 May 2015 11:54

- Hits: 240

WC/Co cemented carbide is the most common material for rock drilling due to its superior combination of toughness and hardness. A cemented carbide rock drill button with 94-wt.% WC and 6-wt.% Co was sliding against polished granite, magnetite, hematite, quartzite, mica schist, leptite and sandstone in a pin-on-disc tribometer. When the test was performed in 25 °C and 350 °C air and also in 25 °C water. The load was chosen to 20 N (which is considerably lower than required for crushing the rock) and the sliding velocity was 0.26 m/s. The relationship between the known wear behaviour against different rock types and the corresponding sliding friction performance is listed as follows,

At 25 °C, the cemented carbide exhibited the highest stable dry friction against mica schist, and the lowest against leptite. At 350 °C, leptite gave the highest friction and hematite the lowest. In water, granite showed the highest friction and quartzite the lowest. A “remaining water lubricant effect” was noticed where mica schist was able to keep low, water lubricated friction value even when seemingly run dry, while leptite, sandstone and hematite were not.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Fabrication Method for Carbide Drilling Rig

- Details

- Category: Tungsten Information

- Published on Thursday, 07 May 2015 11:52

- Hits: 288

A carbide drilling rig, comprising: a drill string containing at least one section of pipe; a drilling tool connected to said drill string and containing at least one carbide component; and surface equipment capable of rotating said drill string and drilling tool; wherein the carbide component comprises a body portion of carbide and an outer layer which is attached to said body without a transition layer or adherent material and which contains an ultra-hard material.

A fabrication method for a carbide drilling tool, comprising the steps of: forming a body portion comprising tungsten carbide; sintering body portion sufficiently to permit handling of body portion for further processing; applying a coating to a working surface of said body portion, coating comprising an ultra-hard material; after said applying step, subjecting said body portion and coating to a high temperature, high-pressure process to form a finished carbide component; and installing finished carbide component in a drilling tool.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Piercing Projectile Power of Tungsten Shaped Charge Liner

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 May 2015 17:12

- Hits: 236

Use high density materials to produce High Explosive-Anti-Tank cover, such as tungsten alloy counterweight, to enhance piercing projectile power, then replace the traditional copper shaped charge liner materials.In order to meet the needs of future war, and is being studied in many countries of the world.United States, Ken Fok company,comparison with copper hood,tungsten-copper-nickel armor-penetration depth of liner more than 31%,comparison with copper hood.Germany, and France's researchers had also confirmed this, with tungsten alloy formed by tungsten shaped charge liner with two characteristics of the shaped charge liner with high performance.High density and high elongation of the Jet before breaking led its extension.

Tungsten-copper-nickel alloy liner shaped charge on homogeneous armor penetration will increase 38%, forming the Jets better than the tensile properties of the copper Jet, but it must be noted that tungsten-copper-nickel alloy liner is not the density, the higher the better the armor, it is important to ensure materials have good uniformity.Uniform density distributions of a single CAP, no defects, experiments show that material with tungsten-copper-nickel alloy liner to enhance penetration power is very effective and feasible.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Advantages of Choosing Tungsten Alloy Balance Weight in Racing Car

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 May 2015 17:09

- Hits: 292

Tungsten heavy alloy(WHA) balance weight of racing car is now becoming the most popular material for ballast, due to its main advantages as follows:

Highest density: Adding WHA balance weight into the whole framework of aracing car is helpful to optimize the performance of the racing car during the racing progress, which contributes to the better control of the car’s movement.

High tensile strength and good creep resistance: Tungsten has high tensile strength and good creep resistance with a high mass/size ratio, so it will be the ideal to work in are strict space. Its high density also gives enhanced sensitivity by increasing the control of load distribution.

Machined Easily: WHA is also easily machineable which gives designers greater flexibility in deciding on the final shape of components and offer designers several advantages over conventional balance materials e.g. lead or steel.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How Tungsten Alloy Counterweight Used in Racing Weights

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 May 2015 17:06

- Hits: 268

Drivers consistently report they can sense differences in how a car handles on the track if the weight on a given wheel varies only by a couple of pounds. Fine tuning a car to a given track is a very cumbersome and time consuming ordeal with conventional lead plate weights.

WHA weight blocks offer up to 50% more weight in a given volume, with the added advantages of direct attachment via threaded holes orthru-bolting and the freedom from deformation. The high density of WHAs permit weights to be placed in the lower half of NASCAR weight adjustment tubes,effectively lowering the overall center of gravity for improved handling.Tungsten product has a specialized line of racing weights for these applications.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Laminated Carbide Cutting Tool Insert

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 May 2015 14:24

- Hits: 232

The insert has a cemented metal carbide core containing a majority of tungsten carbide and possibly other metal carbides bonded with an iron group metal, e.g. cobalt, nickel or iron providing a tough, deformation resistant material which can withstand the stresses of machining.

The core material has a thin layer of crater-resistant cemented carbide disposed on the rake face thereof, said crater-resistant layer containing tungsten carbide and substantial amounts of a carbide of a metal chosen from Groups IVb and Vb of the periodic table, the percentage of the Group IVb and Vb carbides is greater in the crater-resistant layer than in the core material. A thin coating of hard surface material coated on the composite substrate's rake face and flanks provides a coated, laminated structure which is resistant to cratering, flank wear and deformation even under high speed machining conditions.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Titanium Carbide Tool

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 May 2015 14:18

- Hits: 228

Pure titanium carbide tool has excellent crater resistance but only limited strength; however, the laminated composite substrate under the titanium carbide coating supports and supplements the titanium carbide coating extending the useful life of the insert even after the titanium carbide coating has been abraded away.

It is also thought that the TiC coating reduces machining temperatures because of its low frictional coefficient even though it is a very thin coating and provides protection from heat buildup in the laminated composite substrate during cutting operations. A further hard surface coating is aluminum oxide which when coated over the composite substrate produces an insert combining the toughness of the carbide with the wear resistance and low reactivity of aluminum oxide.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Tool Crater Resistant Layer

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 May 2015 14:11

- Hits: 250

The crater resistant layer disposed on the rake face or faces of carbide tools can be formed in various ways.

One method is compacting a mixture of powders having the desired composition of the green core and then placing a layer of a second mixture of powder having the desired proportions for the green crater-resistant layer on top of the green core and compacting both mixtures followed by sintering the resulting green compacted laminate using standard techniques to form a finished cemented carbide material.

As an alternative, previously formed, green unsintered layers of carbide materials having the desired proportions for the various layers could be laminated and compacted together followed by sintering as above to form a laminated cemented metal carbide composite substrate.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Tool Binder Phase

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 May 2015 14:04

- Hits: 247

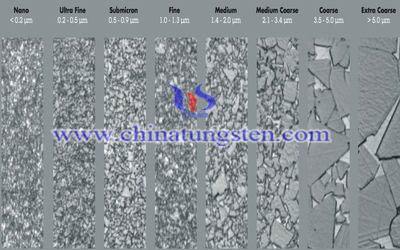

When the content of the binder phase in the cemented carbide tool is 5 to 7 mass %, the mean particle size of the hard phase is 0.6 μm to 1.0 μm, saturation magnetization is 9 to 12 μTm3/kg, the coercive force Hc is 15 to 25 kA/m, and the oxygen content is 0.045 mass % or less. Consequently, the resulting cemented carbide has high hardness and high toughness.

When the cemented carbide is used in a cutting tool, the resulting tool is excellent in wear resistance and fracture resistance. Because of low content of the binder phase, a work material made of a Ti alloy or a heat resistant alloy is less likely to be welded and thus it is possible to prevent chipping of the cutting edge due to welding and a become rough in surface roughness of the worked surface.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com