Heat Treatment Process of Cemented Carbide Balls

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 September 2025 18:27

- Hits: 13

The heat treatment process of cemented carbide balls is mainly used to optimize their properties, such as improving hardness, wear resistance and fatigue resistance, while ensuring dimensional accuracy and surface quality.

Production Process of Tungsten Cemented Carbide Balls

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 September 2025 18:25

- Hits: 14

The production process of tungsten cemented carbide balls primarily involves powder metallurgy combined with precision machining techniques. The following is an overview of the carbide ball production process:

Tungsten Cemented Carbide Balls Processing Equipment

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 September 2025 18:23

- Hits: 15

Tungsten cemented carbide balls processing equipment is primarily determined by the production process, involving multiple steps such as pulverizing, mixing, pressing, sintering, and finishing. The following are common types of processing equipment and their functions, organized based on the characteristics of tungsten cemented carbide balls production:

Tungsten Carbide Balls Production Equipment

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 September 2025 18:21

- Hits: 13

The production of tungsten carbide balls involves multiple precision processes, requiring equipment covering raw material processing, forming, sintering, and post-processing. The following are key pieces of equipment and their functions:

Production Technology of Tungsten Carbide Balls

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 September 2025 17:49

- Hits: 18

Tungsten carbide balls production primarily involves powder metallurgy, combined with high-precision machining and heat treatment techniques. The following are the key production steps and methods:

Tungsten Carbide Balls Production Steps

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 September 2025 17:47

- Hits: 14

The production of tungsten carbide balls incorporates advanced technologies such as powder metallurgy, precision pressing, and high-temperature sintering. Each step requires strict control to ensure the product possesses superior properties such as high hardness, high wear resistance, and corrosion resistance.

Tungsten Carbide Balls Manufacturing Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 September 2025 17:45

- Hits: 13

The manufacturing process for tungsten carbide balls primarily includes the following steps, covering the entire process from raw material preparation to finished product inspection:

The Effect of Crystal Structure on the Properties of Cemented Carbide Balls

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 September 2025 17:42

- Hits: 11

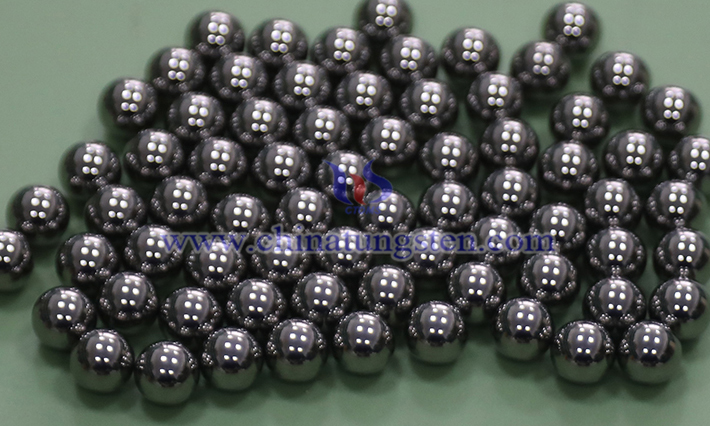

Cemented carbide balls are spherical products made through powder metallurgy, using tungsten carbide (WC) as the primary hard phase and a metal such as cobalt (Co) as a binder phase. Their crystal structure (including the crystal type, lattice parameters, defects, and interfacial structure of the hard and binder phases) plays a decisive role in properties such as hardness, toughness, wear resistance, and corrosion resistance.

Crystal Structure of Tungsten Cemented Carbide Balls

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 September 2025 17:40

- Hits: 15

Tungsten cemented carbide balls are spherical products made of cemented carbide. Their core component is typically a tungsten carbide (WC) matrix, with metal binders such as cobalt (Co) and nickel (Ni). Their crystal structure is primarily determined by the phase structures of the tungsten carbide and the metal binder.

Microstructural Characteristics of Cemented Carbide Balls

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 September 2025 17:38

- Hits: 13

Cemented carbide balls are typically manufactured through a powder metallurgy process using a refractory metal, tungsten carbide (WC), as the hard phase and an iron-group metal (such as cobalt, Co, nickel, etc.) as the binder phase. They are high-performance materials commonly used in bearings, valves, oil drilling balls, and mining tools. Their microstructural characteristics have a decisive influence on mechanical properties, wear resistance, and corrosion resistance. Specific characteristics are as follows:

sales@chinatungsten.com

sales@chinatungsten.com