Tungsten Wire Applications in Floodlights

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 15:31

- Written by Zhenghua

- Hits: 8

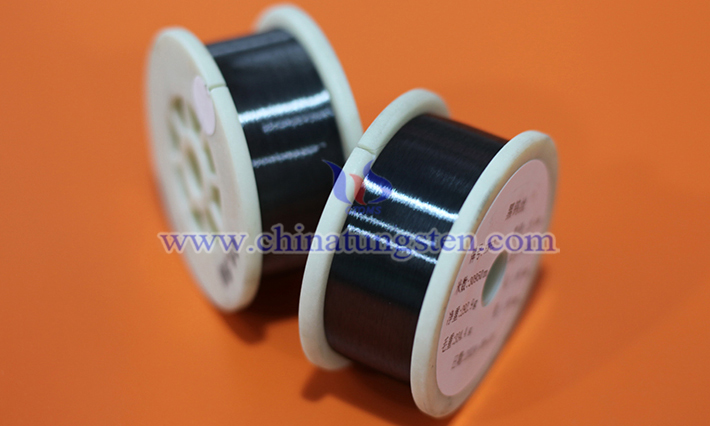

Tungsten wire floodlights (especially halogen tungsten wire lamps) maintain their unique optical properties in film and television production, stage lighting, and professional photography, even as LED technology has become mainstream.

Tungsten wire Applications in Automotive Lighting

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 15:28

- Written by Zhenghua

- Hits: 6

Tungsten wire has long played a crucial role in automotive lighting, particularly in traditional halogen automotive lamps.

Differences Between Tungsten Disulfide and Tungsten Diselenide

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 11:39

- Written by Xiaoting

- Hits: 15

Tungsten disulfide and tungsten diselenide are typical compounds of the rare metal tungsten, both formed by combining the transition metal element tungsten with chalcogen elements (oxygen group elements). Both exhibit excellent physical, chemical, and thermal properties and are widely used in the optoelectronic field. However, there are significant differences between them in terms of specific concepts, properties, and applications. These differences stem from the distinct characteristics of sulfur and selenium, the chalcogen elements involved, which in turn lead to variations in their crystal structures, electronic bandgaps, and chemical stabilities. Such differences further result in their pergent performance in optoelectronic devices, catalytic reactions, and lubrication applications, making each compound suitable for specific scenarios based on its unique attributes.

YG6 Tungsten Steel

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 11:37

- Written by Xiaoting

- Hits: 15

1.What is YG6 Tungsten Steel?

YG6 tungsten steel is a tungsten-cobalt hard alloy, a medium-grain tungsten-cobalt alloy composed of tungsten carbide (WC) powder and cobalt (Co) powder, with WC powder accounting for 94% and cobalt powder for 6%.

Tungsten Resin

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 11:32

- Written by Xiaoting

- Hits: 15

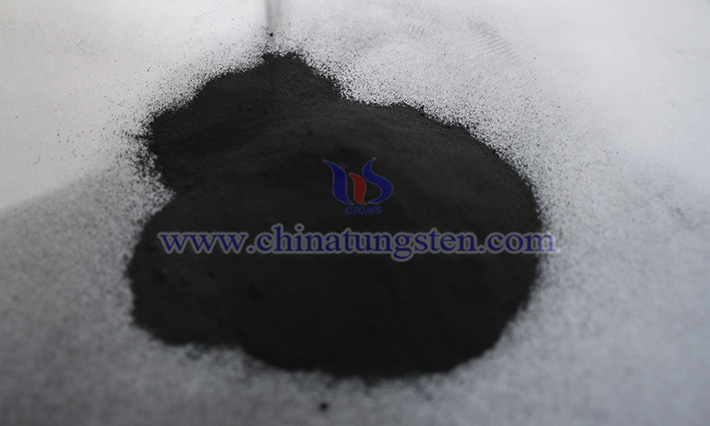

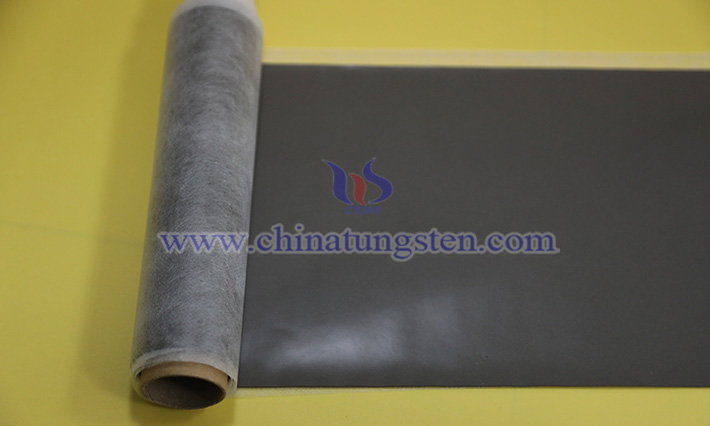

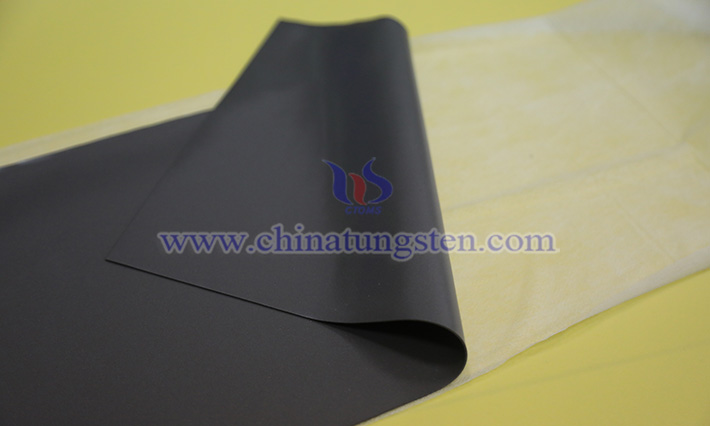

As a typical novel tungsten product, tungsten resin is a synthetic resin product formed by combining high-purity tungsten powder with various resin materials in different proportions. It is a gray-black material resulting from the combination of a transition metal and organic compounds, known in English as "Tungsten resin." Commonly used resin materials include nitrile rubber, chlorinated polyethylene, polypropylene, polybutene, polyurethane, and thermoplastic materials.

Main Applications of Tungsten Resin

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 11:30

- Written by Xiaoting

- Hits: 15

Tungsten resin, also known as resin tungsten alloy, tungsten-filled polymer, or tungsten polymer, is a product formed by mixing various resins (such as nitrile rubber, chlorinated polyethylene, polypropylene, polybutene, etc.) with transition metal tungsten powder through special metallurgical techniques. It is a gray-black solid material under normal temperature and pressure, featuring non-toxic, environmentally friendly, non-radioactive, high specific gravity, good plasticity, excellent hydrophobicity, strong radiation resistance, corrosion resistance, and oxidation resistance. As a result, it is widely used in aerospace, aviation, maritime, automotive, medical, and nuclear industry fields.

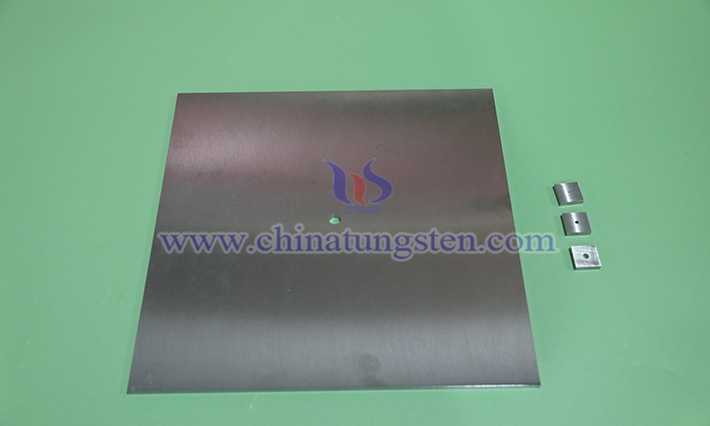

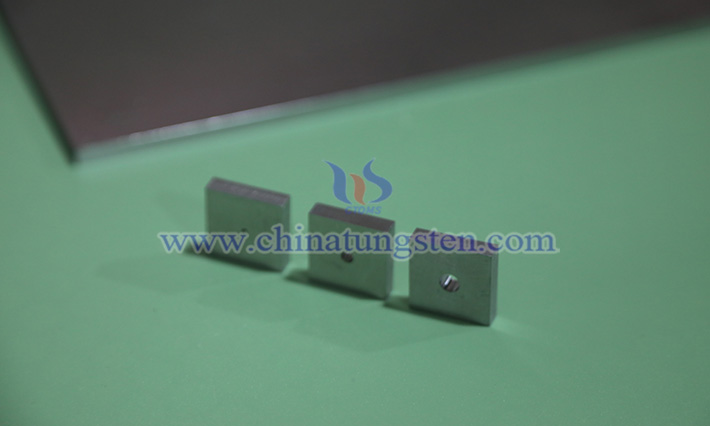

Pinhole Tungsten Alloy Collimator

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 August 2025 19:55

- Written by Xiaoting

- Hits: 17

Pinhole tungsten alloy collimator is a critical component widely used in nuclear medicine imaging and radiation detection fields. It restricts the direction of radiation beams through a small hole (pinhole), thereby enhancing image resolution and accuracy. Due to its high density, tungsten alloy effectively absorbs and shields high-energy rays, such as gamma rays. Compared to traditional lead collimators, tungsten alloy collimators offer significant advantages in image quality, radiation protection, and manufacturing flexibility.

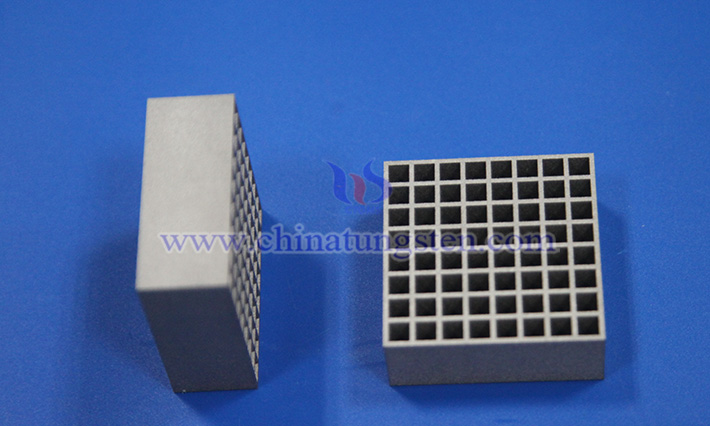

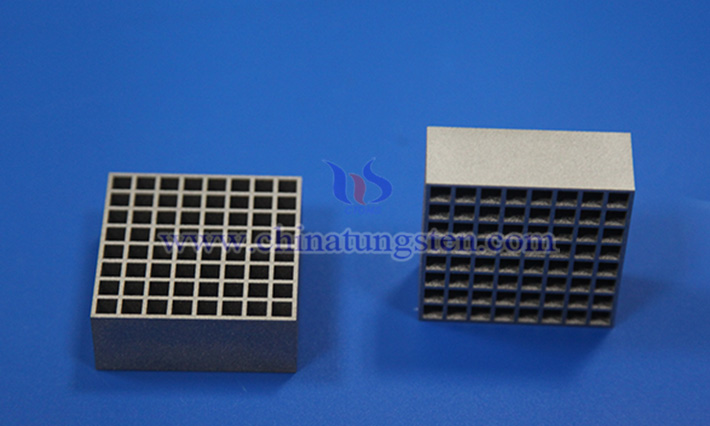

Production Methods of Tungsten Alloy Collimators

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 August 2025 19:51

- Written by Xiaoting

- Hits: 18

The production of tungsten alloy collimators combines material characteristics with manufacturing technologies, with mainstream methods including powder metallurgy, precision machining, powder injection molding, and others. These production methods cater to products with varying structural complexity and precision requirements, collectively ensuring the collimators' efficiency and stability in radiation control.

Comparison of Tungsten Alloy Collimators and Lead Collimators

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 August 2025 19:48

- Written by Xiaoting

- Hits: 16

Tungsten alloy collimators, in competition with lead collimators in the field of radiation control, have gradually become the mainstream choice due to their unique composition and performance advantages. In terms of composition, tungsten alloy collimators use tungsten as the base, typically alloyed with elements such as nickel, iron, and copper to form alloys like tungsten-nickel-iron or tungsten-nickel-copper, with tungsten content reaching over 90%. This composition provides high density, high strength, and good processability. In contrast, lead collimators are mainly made of pure lead or lead-antimony alloys, where antimony enhances mechanical strength, but the material remains relatively soft overall.

Features of Tungsten Alloy Collimators

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 August 2025 19:46

- Written by Xiaoting

- Hits: 15

As a critical radiation control component, the tungsten alloy collimator, with its unique material properties and structural design, exhibits numerous significant features in medical, nuclear industry, and scientific research fields, making it an ideal replacement for traditional lead collimators.

sales@chinatungsten.com

sales@chinatungsten.com