Tungsten Trioxide Applied for FTO Conductive Glass

- Details

- Category: Smart Glass

- Published on Tuesday, 09 April 2019 16:37

- Written by Yahong

- Hits: 1856

Tungsten trioxide can be applied to the FTO conductive glass in the form of a seed crystal liquid. Specifically, it is necessary to prepare a tungsten trioxide seed crystal liquid first:

A certain amount of hydrated sodium tungstate was dissolved in deionized water to prepare a 0.2mol/L solution. After the sodium tungstate was completely dissolved, about 15mL of a 3mol/L hydrochloric acid solution was added dropwise while stirring, and the sodium tungstate was converted into tungstic acid precipitate. Then, the precipitate was centrifuged several times and washed until the pH was approximately equal to 7. Finally, 30% hydrogen peroxide was added dropwise to the washed precipitate to dissolve it and finally form a clear sol, which was placed in the refrigerator for use.

More details, please visit:

http://www.tungsten-powder.com/tungsten-oxide.html

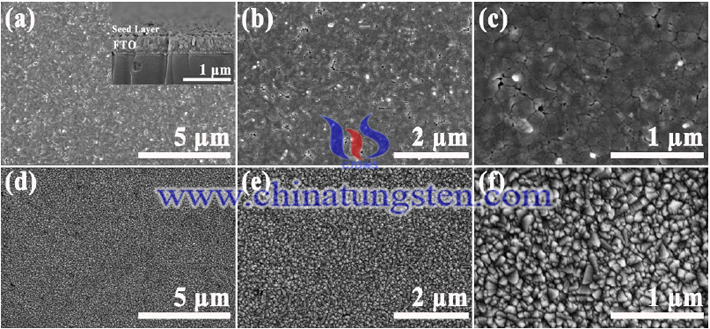

Next, an FTO conductive glass coated with a tungsten trioxide seed crystal layer was prepared by a sol-gel method. Specifically, the FTO conductive glass is immersed in acetone, alcohol, deionized water for ultrasonic cleaning for 15 minutes, and dried in an oven at 80°C. After cooling to room temperature, the seed crystal liquid is uniformly applied to the surface of the FTO by spin coating, and then after incubating at 400°C for 1h, FTO conductive glass covered with a WO3 seed crystal layer of about 80nm thick was obtained, as shown above, wherein a-c is the SEM images of FTO conductive glass coated with a seed crystal layer at different multiples; d-f is a SEM images of ordinary FTO conductive glass at different multiples; a is a cross section of the seed crystal layer.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com