Applications of Cut-Resistant Tungsten Wire in the Electronics and Information Industry

- Details

- Category: Tungsten Information

- Published on Monday, 17 March 2025 18:58

- Hits: 157

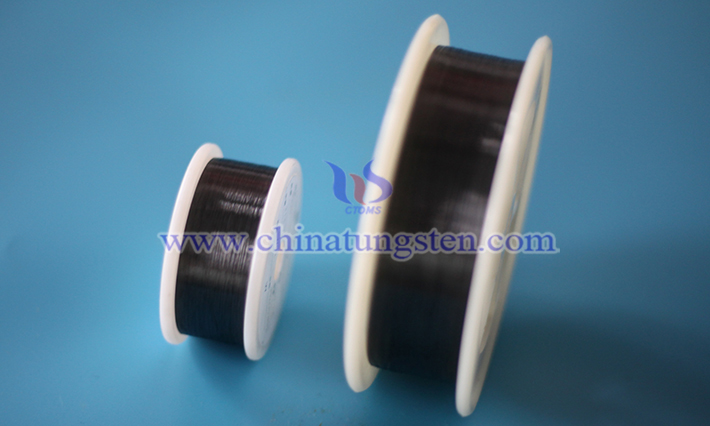

Cut-resistant tungsten wire, with its high strength, heat resistance, wear resistance, and excellent conductivity, plays a vital role in the electronics and information industry, particularly in miniaturized and high-reliability scenarios. Below is a detailed analysis of its primary applications:

1. Semiconductor Manufacturing and Processing

Wafer Cutting Tools: Tungsten wire can be processed into high-precision wire saws to cut hard, brittle materials like silicon wafers or sapphire. In multi-wire sawing technology, its wear resistance ensures stable cutting quality.Grinding and Polishing Materials: Tungsten-based composites are used as grinding heads or support structures in Chemical Mechanical Polishing (CMP) processes, enhancing durability and precision.

2. Interconnection and Packaging in Microelectronics

High-Temperature Bonding Wires: In high-temperature packaging (e.g., power devices), tungsten wire serves as bonding wire, offering superior mechanical strength and creep resistance compared to gold or copper, ideal for high-frequency and high-temperature environments.Microelectronic Interconnects: Used for precision conductive connections in microsensors or MEMS devices, its stress resistance enhances component reliability.

3. Display Technology

OLED/LCD Electrode Material: Tungsten wire acts as ultra-fine electrodes (e.g., metal grids) in high-resolution displays. Its strength supports ultra-thin structures while minimizing electrical losses.Photomask Support: In photolithography, tungsten wire grids serve as support structures for photomasks, ensuring imaging accuracy.

4. Printed Circuit Board (PCB) Manufacturing

High-Density Micro-Drill Bits: Tungsten alloy micro-drills are used for precision holes in multi-layer PCBs, with wear resistance extending tool lifespan and reducing costs.Flexible PCB Reinforcement: Embedding tungsten wire layers in FPCs improves mechanical strength without compromising flexibility.

5. MEMS and Sensors

Suspended Structural Support: Ultra-thin tungsten wire is used as support beams for movable structures (e.g., accelerometers) in MEMS, ensuring sensitivity and fatigue resistance.High-Temperature Sensor Leads: Tungsten wires act as stable conductors for temperature sensors in aerospace or automotive electronics, operating reliably in extreme heat.

6. Optoelectronics and Communications

Fiber-Optic Alignment Components: Tungsten wire is used in high-precision fiber alignment fixtures for optical connectors, leveraging rigidity for long-term positional stability.Vacuum Electron Device Electrodes: In devices like traveling-wave tubes or magnetrons, tungsten wire serves as high-temperature electrodes (e.g., emitters or grids) for high-frequency signal processing.

7. EMI Shielding

Composite Shielding Materials: Tungsten-polymer composites form lightweight EMI shielding layers for high-frequency device housings or connectors, balancing shielding efficiency and structural integrity.

Cut-resistant tungsten wire, leveraging its unique physical properties, has become critical in precision manufacturing and high-performance components for the electronics industry. As microelectronics continue to miniaturize and evolve, its potential will expand further. Future advancements may include nano-level structural designs and multi-functional composites to meet emerging technological demands.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com