Tungsten Wire: The Temperature Guardian in Glass Heating Equipment

- Details

- Category: Tungsten Information

- Published on Thursday, 26 June 2025 19:21

In processes such as glass melting, forming and sealing, heating equipment needs to operate stably at high temperatures far exceeding 1,000 degrees. When common alloy materials yield at high temperatures, tungsten wire becomes the key support in this extreme thermal field with its excellent physical properties.

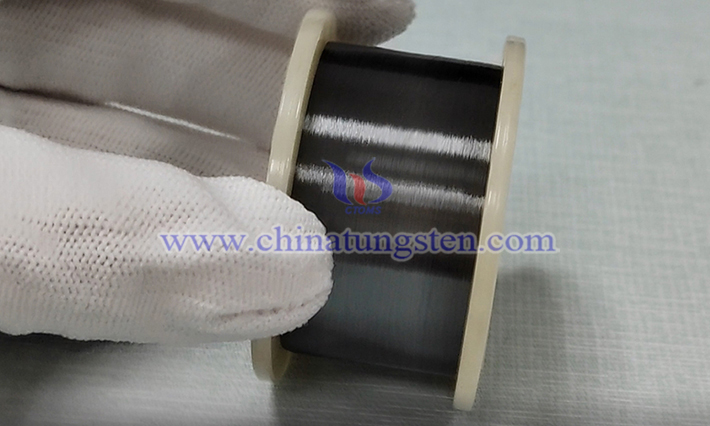

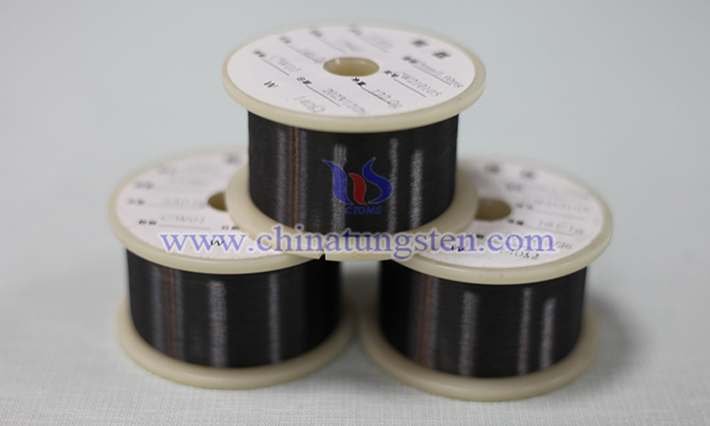

1. Material Endowment of Tungsten Wire

The core advantage of tungsten comes from its unparalleled melting point (3422°C), which is the best among metal elements. This gives tungsten wire the absolute ability to maintain solid structural integrity within the glass processing temperature range of 1500°C - 2200°C. In comparison, nickel-chromium alloys (such as Cr20Ni80) have a melting point of about 1400°C, and molybdenum wire has a high melting point (2623°C), but it still faces significant softening and deformation risks under long-term high temperatures.

Tungsten wire has excellent mechanical properties and stability in extreme thermal environments:

(1) High temperature strength and creep resistance: At 1500°C, its tensile strength can still maintain about 15% of that at room temperature, far exceeding that of most metals. Its high recrystallization temperature (usually above 1200°C, which can be further increased by doping) effectively inhibits grain coarsening and significantly improves its resistance to high temperature creep, ensuring that the heating element is not easy to sag or deform under long-term high temperature load.

(2) Resistance stability: Tungsten has a moderate resistivity and its temperature coefficient of resistance is positive. In the high temperature operating range, its resistance characteristics are relatively stable, which is conducive to precise power control, which is crucial for the precise control of the temperature curve in the glass process.

2. Application and Protection of Tungsten Wire

The weakness of tungsten at high temperature is that it will oxidize in an oxygen-containing atmosphere to generate volatile WO₃, resulting in application failure. Therefore, in glass heating equipment, the use of tungsten wire requires certain protective measures:

(1) Vacuum environment: A high vacuum environment completely eliminates the oxidation source.

(2) Reducing atmosphere: Used in an inert gas environment.

3. The Importance of Tungsten Wire in Glass Thermal Engineering

In the core high-temperature area of glass heating equipment - especially in places where temperatures above 1400°C need to be maintained accurately, stably and for a long time, such as high-quality glass melting furnaces, special glass fiber drawing furnaces, precision glass sealing equipment, etc. - tungsten wire has become an irreplaceable heating element due to its unparalleled high-temperature strength, rigidity and structural stability. Although its brittleness and high cost are objective, tungsten wire still stands out in the cutting-edge field of glass technology that pursues extreme temperature and stability.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com