Tungsten Oxide One-dimensional Nano Material and Preparation Method

- Details

- Category: Tungsten Patents

- Published on Tuesday, 14 October 2014 14:17

- Written by Sherry

- Hits: 2426

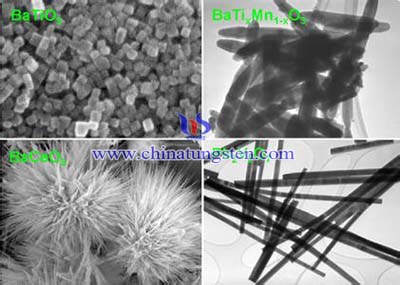

The present invention aims to provide a one-dimensional tungsten oxide material and preparation method, using a simple hydrothermal preparation, operation is simple, easily available raw materials, low cost, environmentally friendly non-toxic solvent that can a large number of synthesis, preparation of WO3 nanowires superior performance, versatile, suitable for large-scale promotion, with significant economic benefits.

The present invention is one-dimensional material is tungsten oxide tungsten oxide nanowires, a length of several hundred nanometers to several microns, width 5-20 nm.

The present invention is a one-dimensional tungsten oxide material preparation method: distilled water elemental tungsten powder are mixed, stirred in an autoclave, the reactants at the reaction temperature 423-478K 1-30 days, then filtered, 323-373K temperature drying 12-24h obtain said tungsten oxide one-dimensional nanomaterials.

The present invention is a significant advantage: The present invention at lower temperatures and does not add any surface active agents and conditions, the templating agent, a simple hydrothermal method of WO3 nanowires prepared, the operation is simple, readily available raw materials get low cost, environmentally friendly non-toxic solvent, can be a lot synthesis, preparation of WO3 nanowires superior performance, versatility, is a good new energy materials that can be used photoelectrocatalysis, solar cells, sensors, lithium ion batteries and Field emission, etc.; suitable for large-scale promotion, with significant economic benefits.

The present invention is a one-dimensional tungsten oxide material preparation, characterized in that: said one-dimensional nano material is tungsten oxide tungsten oxide nanowires, a length of several hundred nanometers to several microns, width 5-20 nm, preparation process as follows: the distilled water elemental tungsten powder are mixed, stirred in an autoclave, the reactants in the reaction at a temperature 423-478K 1-30 days, then filtered and dried at a temperature 323-373K 12-24h to give the said one-dimensional materials, tungsten oxide, wherein the amount of reactor volume of distilled water for 50 to 75 volume% elemental tungsten powder in an amount of 0. 01 ~ 0. 5g, the amount of distilled water with a weight ratio of 1:50 ~ 1: 3750.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The above is reproduced from: Application Technology Network, if in doubt, please contact the content belongs website.

Method for Producing High-purity Tungsten Powder

- Details

- Category: Tungsten Patents

- Published on Saturday, 11 October 2014 09:05

- Written by Sherry

- Hits: 2726

The present invention relates to a method for manufacturing a phosphorus content of less than 1 ppm by weight of a high-purity tungsten powder, wherein the ammonium tungstate solution in accordance with the amount of the tungsten inclusions are translated ppm by weight of a phosphorus-containing impurities as the starting material above , by the following 50 ℃ using hydrochloric acid in which and the pH was adjusted to 4 and less than 7, so that eleven hydrated ammonium paratungstate crystalline precipitate, which was further heated to 70 ~ 90 ℃, filtered at a high temperature to obtain a pentahydrate crystals of ammonium paratungstate, and then the crystals of ammonium paratungstate pentahydrate obtained tungsten oxide calcined, and the hydrogen reduction of tungsten oxide to obtain a high-purity tungsten powder.

The present invention also relates to a phosphorus content of 0.4 ppm by weight of high-purity tungsten powder manufacturing method is characterized in that, in the use of hydrochloric acid and the pH adjusted to 4 steps or more and 6 or less, and follow the same procedure to give high purity tungsten powder. Accordingly, the phosphorus content can be effectively reduced.

A phosphorus content of less than I ppm by weight of the manufacturing method of high-purity tungsten powder, wherein the amount of tungsten inclusions in accordance with the translation of phosphorus-containing impurities I ppm or more by weight of ammonium tungstate solution as a starting material, By below 50 ° C with hydrochloric acid to which, and the PH was adjusted to 4 and less than 7, so that eleven hydrated ammonium paratungstate crystalline precipitate, which was further heated to 70 ~ 90 ° C, filtered at the heating temperature state pentahydrate obtained crystals of ammonium paratungstate, and then the crystalline pentahydrate paratungstate tungsten oxide obtained by calcining, and the hydrogen reduction of tungsten oxide to obtain a high-purity tungsten powder.

A manufacturing method of a phosphorus content of 0.4 ppm by weight of a high-purity tungsten powder, wherein the ammonium tungstate solution in accordance with the amount of the tungsten inclusions are translated by weight PPm I phosphorus containing impurities as the starting material in the above By 50 ° C and less hydrochloric acid for neutralization to adjust the pH to 4 or more and 6 or less, so that eleven hydrated ammonium paratungstate crystalline precipitate, which was further heated to 70 ~ 90 ° C, filtered at the heating temperature condition pentahydrate obtained by crystallization of ammonium paratungstate, and then the crystalline pentahydrate calcining ammonium paratungstate obtained tungsten oxide, tungsten oxide and the reduction with hydrogen and made of high-purity tungsten powder.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The above is reproduced from: Application Technology Network, if in doubt, please contact the content belongs website.

Manganese-chromium-tungsten Bainitic Steel

- Details

- Category: Tungsten Patents

- Published on Thursday, 09 October 2014 08:52

- Written by Sherry

- Hits: 2627

The present invention describes a manganese-chromium-tungsten bainitic steel, belongs to steel alloy technology field. Characterized in that: it comprises the following components, its percentage by weight: C0.06 ~ 0.55wt. %; Mn1.90 ~ 3.00wt. %; Si0.20 ~ 2.00wt. %; Cr0.10 ~ 2.00wt. %; W0.10 ~ 1.00wt. %; Remainder being Fe.

Steels of the invention is a new class of manganese-chromium-tungsten bainitic steel, manganese, silicon, chromium as the main alloying elements, plus tungsten as the main and auxiliary elements, with high strength and toughness and bainite air cooling hardenability, under air cooling conditions can be obtained bainite / martensite phase complex organization, exempt from hardening process for the manufacture of a variety of shaft parts, structural parts, all kinds of springs, wear parts, precision molds and resistance grinding steel castings.

Manganese-chromium-tungsten bainitic steel after tempering with excellent strength and toughness, which can close substitutability quenched and tempered steel, used to make a variety of high-strength structural parts, and surface hardening.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The above is reproduced from: Application Technology Network, if in doubt, please contact the content belongs website.

Composite Tungsten Rod Heater for Sapphire Crystal Growth

- Details

- Category: Tungsten Patents

- Published on Friday, 10 October 2014 08:59

- Written by Sherry

- Hits: 2737

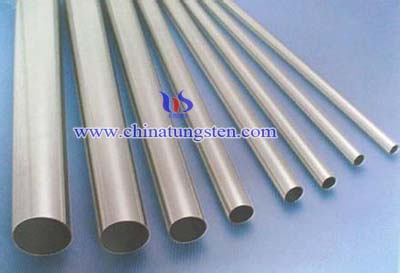

The utility model is crystal processing techniques, and, more specifically, a sapphire crystal is a crystal growth furnace used for the growth of the composite tungsten rod heater.

Currently, the prior art method of sapphire crystal growth is generally used Kyropoulos, Kyropoulos sapphire crystals grown using tungsten rod heater, the heater is made of tungsten rod diameter and a length of 4 ~ IOmm tungsten rods is formed by bending a circular heater assembly of the cage-like structure, the diameter and the number of cage-shaped heater according to the temperature required for the tungsten rods conditions Kyropoulos course be selected, however, the tungsten cage Stick heater has the following significant disadvantages:

1) Due to the bending processing of the tungsten rod bow 丨 into more stress is easily deformed such that the bottom heater is broken, short life;

2) High temperature stability is not good, easy to deformation caused by uneven temperature field, affecting the quality of products;

3) Repair and maintenance costs are higher.

In order to solve the above problems, the utility model provides a long life, stable temperature performance, temperature field uniformity, lower repair and maintenance costs of sapphire crystal growth composite tungsten rod heater, its specific programs: the sapphire crystal growth by the heater bar and the composite tungsten copper electrode rod tungsten, tungsten plate, fixing nut, fixed tungsten rings, characterized in that the fixed ring is set to a circular tungsten, tungsten rod fixed at uniform tungsten ring, tungsten the upper end of the rod is provided a copper electrode, the lower end of the tungsten bar tungsten plate is provided, by fixing the upper end of the tungsten rod and a nut fixed to the copper electrode connected to a lower end fixed by a tungsten rod with a tungsten plate fixedly connected to the nut.

1 conjunction with the accompanying description of the utility model in more detail, so that the public a better understanding of the practical implementation of the new method, the utility model specific embodiments are: sapphire crystal growth of the composite made of copper tungsten rod heater an electrode, tungsten rod 2, tungsten plate 3, the nut 4 is fixed, consisting of a fixed tungsten ring 5, characterized in that the tungsten ring 5 is set to a fixed circular, fixed ring 5 is disposed uniformly tungsten tungsten rod 2, the upper end of the tungsten rod 2 providing a copper electrode 1, 2 is provided with a lower end of the tungsten bar tungsten plate 3, the upper end of the tungsten rod 2 is fixed by the fixing nut is connected to the copper electrode 4 I, the lower end of the tungsten rod 2 is fixedly connected to the fixing nut 4 by tungsten plate 3.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The above is reproduced from: Application Technology Network, if in doubt, please contact the content belongs website.

Tungsten Metal-casting Skateboard

- Details

- Category: Tungsten Patents

- Published on Wednesday, 08 October 2014 14:09

- Written by Sherry

- Hits: 2670

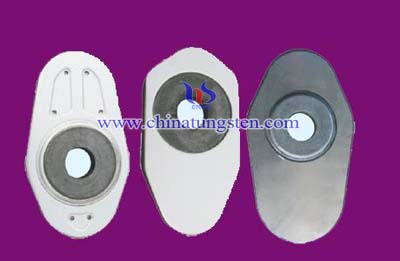

The present invention describes a long-life tungsten metal-casting skateboard, about a steelmaking and continuous casting equipment.

This invention relates to provide a long-life expectancy of tungsten metal-casting the slide, which can increase the service life of the slide casting 1-2 times.

Aspect of the present invention is a tungsten containing metal casting long-life skateboard, comprising a base material, the matrix material contains a metal tungsten powder. Tungsten powder and the weight percentage of the matrix material is from 0.5 to 2.0%. The metal tungsten powder as the powder through a 200-mesh sieve, the content of W ≥99.5%. The drying temperature is 150-220 ℃, the firing temperature is 1200-1450 ℃.

The present invention is used in steelmaking and continuous casting production equipment.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The above is reproduced from: Application Technology Network, if in doubt, please contact the content belongs website.

sales@chinatungsten.com

sales@chinatungsten.com