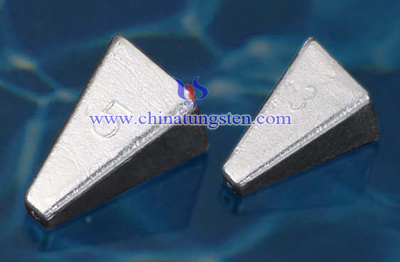

Tungsten Pyramid Fishing Sinkers

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 September 2014 09:09

- Written by Sherry

- Hits: 633

Tungsten Pyramid fishing sinkers also has a line eye like bell sinkers, which giving it an inverted pyramid profile when tied. They are excellent tungsten fishing sinkers for holding a rig in place in sandy bottoms, or in rough water, the pyramid is probably the best sinker for ocean conditions. It casts well and is a tenacious anchor, it excels in strong currents with any bottom condition. Their streamline profile causes them to sink quickly, and their flat edges prevent them from being rolled along bottom in fast currents. And also it is a superb sinker for bay and ocean fishing. The one drawback is that its stubborn feature often gets it securely snagged on the rocks or other submerged matter. So it's not a good choice for rockfish or river angling.

Tungsten pyramid fishing sinkers is a staple piece of tackle for striper bass and surf fishing as follows. When pyramid fishing sinkers are used in water bodies with sand-floor or mud-floors, the tungsten fishing sinkers will bury themselves into the bottom if the bottom is soft and if it is on hard bottoms, the flat sides will prevent the pyramid from rolling with the current.

For longest time,tungsten pyramid fishing sinkers are made from lead. Other metals are replacing it although lead is still used nowadays. Lead is banned in some fishing areas and anglers are forced to use other sinkers which made from non-toxic materials. The main reason for the coming out of the alternatives is that the lead is toxic and is not friendly to the environment. Tungsten based materials made pyramid tungsten fishing sinkers achieve great honor between anglers because of tungsten based materials are agree with the environment protection.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The Introduction of Tungsten Heavy Alloy

- Details

- Category: Tungsten Information

- Published on Friday, 05 September 2014 17:40

- Written by jwy

- Hits: 556

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Surface Finishes of Tungsten

- Details

- Category: Tungsten Information

- Published on Friday, 05 September 2014 16:29

- Written by Cher

- Hits: 598

A colloidal graphite lubricant, which imparts a black coating to "as drawn" tungsten wire, is used to protect the wire from oxidation and to lubricate the wire as it passes through the die. Many applications require tungsten wire with characteristics other than those obtainable in "as drawn" wire. A variety of processes produce wire with a cleaned surface or with a special finish.

After drawing operations have been completed, the wire may be cleaned by exposure to elevated temperatures in a reducing atmosphere. Treating the surface chemically or electrolytically can also clean tungsten wire. (The diameter of the wire may be further reduced after drawing by electrolytic etching.)

The cleaned wire can be electroplated with such elements as gold, silver, nickel and copper, for use primarily in electronic tubes.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to Extract Tungsten Oxide From the Ores

- Details

- Category: Tungsten Information

- Published on Friday, 05 September 2014 17:11

- Written by jwy

- Hits: 593

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten History

- Details

- Category: Tungsten Information

- Published on Friday, 05 September 2014 16:27

- Written by Cher

- Hits: 614

The word "tungsten" is an adaptation of the Swedish tung sten (heavy stone) and was first applied to the mineral scheelite about 1758. The element was first identified in 1781 by a Swedish chemist, K.W. Scheele, for whom the calcium tungstate mineral, scheelite, was later named. Commercially, tungsten is prepared from scheelite.

Further processing results in a yellow powder of tungsten tri-oxides that would be considered extremely pure by most commercial standards. However, the desired properties of tungsten wire are affected so adversely by minute quantities of unwanted impurities that another purification is added. This consists of re-dissolving the hydroxide, purifying the solution, and crystallizing the tungsten out in the form of ammonium paratungstate.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com