Using of Numerical Simulation for Growing High-Quality Sapphire Crystals by The Kyropoulos Method

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Thursday, 28 November 2013 09:27

- Hits: 2436

In the present work, an advanced numerical model is suggested to analyze heat transfer and flow pattern in  sapphire crystal growth by the Kyropoulos technique. The new approach accounts for radiative heat exchange in the crystal and convection in the melt, and provides prediction of the crystallization front shape. The model allowed the analysis of several growth setup designs and selection of an optimal configuration. The numerical predictions performed with the CGSim software (www.semitech.us) agree well with available experimental data obtained in optimized crystal growth process reported for the first time.

sapphire crystal growth by the Kyropoulos technique. The new approach accounts for radiative heat exchange in the crystal and convection in the melt, and provides prediction of the crystallization front shape. The model allowed the analysis of several growth setup designs and selection of an optimal configuration. The numerical predictions performed with the CGSim software (www.semitech.us) agree well with available experimental data obtained in optimized crystal growth process reported for the first time.

Recent interest in monitoring systems requires very large optical windows that are transmitting over a wide spectral range. Some of the other requirements involve durability, high strength and robustness to withstand severe environments. Therefore, sapphire has been required for these applications. The Heat Exchanger Method (HEM)TM has been used to produce very large sapphire crystals primarily for optical applications. Crystals of 20 cm and 25 cm diameter have been produced in production for over 20 years. Presently, 34 cm diameter boules have been adopted in production, and 50 cm diameter sapphire growth is currently in development. Results of progress and characterization data of the boules will be presented.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Optical Properties of Single-Crystalline ZnO Nanowires on M-Sapphire

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Wednesday, 27 November 2013 09:39

- Hits: 2431

Growth habits and defects in epitaxial ZnO nanowires grown from Au catalyst on (00.1) GaN/sapphire substrate using the vapor-liquid-solid (VLS) technique were studied using electron microscopy and x-ray diffraction. The results revealed presence of both horizontal (crawling-like) and vertical nanowires having similar orientation relationship to the substrate (00.1)ZnO||(00.1)GaN, [11.0]ZnO||[11.0]GaN. The crawling-like growth precedes the vertical growth, and the coalescence and overgrowth of the crawling nanowires produce a highly defective layer which separates the substrate and vertical nanorods. Transmission electron microscopy revealed a high density of planar defects in this interfacial layer. A significant density of stacking faults residing on the (0001) planes was also observed in the shorter vertical nanorods. The crawling nanowires are under residual compressive strain, whereas the vertical nanorods grow strain-free.

using the vapor-liquid-solid (VLS) technique were studied using electron microscopy and x-ray diffraction. The results revealed presence of both horizontal (crawling-like) and vertical nanowires having similar orientation relationship to the substrate (00.1)ZnO||(00.1)GaN, [11.0]ZnO||[11.0]GaN. The crawling-like growth precedes the vertical growth, and the coalescence and overgrowth of the crawling nanowires produce a highly defective layer which separates the substrate and vertical nanorods. Transmission electron microscopy revealed a high density of planar defects in this interfacial layer. A significant density of stacking faults residing on the (0001) planes was also observed in the shorter vertical nanorods. The crawling nanowires are under residual compressive strain, whereas the vertical nanorods grow strain-free.

ZnO nanowires have been synthesized using a catalyst-assisted heteroepitaxial carbothermal reduction approach on a m-sapphire substrate. Intricate and uniform arrays have been obtained with each nanowire forming an angle ∼30° with the substrate normal. Photoluminescence studies at room temperature for wavelengths between 335 and 620 nm reveal a strong single exciton peak at ∼380 nm (3.26 eV) with accompanying deep-level blueshifted emission peaks at ∼486, 490, and 510 nm. UV resonant Raman spectroscopy has been used to characterize the nanowires at room temperature with multiphonon scattering exhibiting phonon quantum confinement.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Numerical Study of Heat Transport and Fluid Flow of Melt And Gas During The Seeding Process of Sapphire Czochralski Crystal Growth

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Tuesday, 26 November 2013 09:21

- Hits: 2597

For the seeding process of the Czochralski crystal growth of sapphire, the flow and temperature field with a  nonflat melt−gas interface have been studied numerically using the finite element method. The configuration usually used initially in a real Czochralski crystal growth process consists of a crucible, active afterheater, induction coil with two parts, insulation, melt, and gas. At first, the electromagnetic field produced by the radio frequency (RF) coil in the whole system and the volumetric distribution of heat inside the metal crucible and afterheater were calculated. Using this heat distribution as a source, the fluid flow and temperature field were determined in the whole system.

nonflat melt−gas interface have been studied numerically using the finite element method. The configuration usually used initially in a real Czochralski crystal growth process consists of a crucible, active afterheater, induction coil with two parts, insulation, melt, and gas. At first, the electromagnetic field produced by the radio frequency (RF) coil in the whole system and the volumetric distribution of heat inside the metal crucible and afterheater were calculated. Using this heat distribution as a source, the fluid flow and temperature field were determined in the whole system.

We have considered two cases: configuration without a gap between crucible and afterheater and with a gap, corresponding to an often used growth situation in our lab. It was shown that an active afterheater and its location with respect to the crucible influences markedly the temperature and flow field of the gas in the chamber and partly also in the melt.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Through The Near Net Shape Crystal Growth Sapphire Production Dome of The Two Methods

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Wednesday, 27 November 2013 09:24

- Hits: 2501

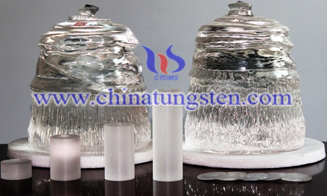

Large sapphire single crystals with the geometry of near net shape domes are grown by the gradient  solidification method (GSM). The growth is carried out in double-wall molybdenum crucibles, and perfect crystals, free of grain boundaries and scattering centers, are produced. The process is used to grow sapphire domes with different crystallographic orientations, including the optical axis. This process significantly shortens the fabrication process of the dome, thus leading to a cheaper, high-quality, product.

solidification method (GSM). The growth is carried out in double-wall molybdenum crucibles, and perfect crystals, free of grain boundaries and scattering centers, are produced. The process is used to grow sapphire domes with different crystallographic orientations, including the optical axis. This process significantly shortens the fabrication process of the dome, thus leading to a cheaper, high-quality, product.

The progress of the liquid-solid interface during crystal growth of sapphire and spinel using the heat exchanger method (HEM) has been studied and related to processing parameters. Crystal growth has thus been optimized to produce crystals with 95–100% of the material free of voids and scattering centers.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Domed Sapphire Crystal Grown by The Gradient Freezing Method (GSM)

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Tuesday, 26 November 2013 09:06

- Hits: 2666

Describes a sapphire single crystal growth, in a dome shape, the gradient freezing method (GSM). Molybdenum  is used in a double-walled crucible planted near net shape geometry. This significantly shortens the final size of the dome to the manufacturing process, thereby reducing costs. This process is used with a different shape (hemispherical, etc.), size (maximum diameter 6 inches) and a crystal orientation (including the optical axis) Growth dome. The growth rate of the thermal field and control the grain boundaries and prevent scattering centers is very important, and for the prevention of the action of surface tension generated geometric distortion.

is used in a double-walled crucible planted near net shape geometry. This significantly shortens the final size of the dome to the manufacturing process, thereby reducing costs. This process is used with a different shape (hemispherical, etc.), size (maximum diameter 6 inches) and a crystal orientation (including the optical axis) Growth dome. The growth rate of the thermal field and control the grain boundaries and prevent scattering centers is very important, and for the prevention of the action of surface tension generated geometric distortion.

Gradient freeze (GSM) is for large, high-quality single-crystal sapphire and calcium fluoride growth. Several growth parameters (eg, thermal gradient, stability, growth rate and the quality of the thermal field in the starting material) of the quality of the grown crystal was studied correlation. Growth of several types of defects are analyzed to clarify its nature. Crystals characterized by its crystalline and optical properties.

Read more: Domed Sapphire Crystal Grown by The Gradient Freezing Method (GSM)

More Articles...

- The Production of EFG Sapphire Ribbon for Heteroepitaxial Silicon Substrates

- Interface Shapes And Thermal Fields During The Gradient Solidification Method Growth of Sapphire Single Crystals

- Sapphire Furnace Require Increasing

- Sapphire Shi Changjing Furnace The Tempered Surgery:Crystal Standard LED Upstream

sales@chinatungsten.com

sales@chinatungsten.com