Tungsten Electrode Tip Choices -Ⅱ

- Details

- Category: Tungsten Information

- Published on Thursday, 27 August 2015 17:17

- Written by Yahong

- Hits: 266

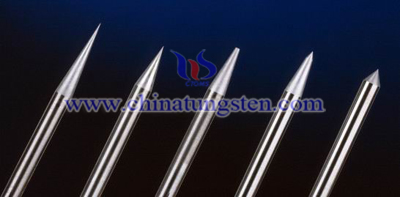

Generally, grind the taper on the tungsten to a distance of less than 2.5 times the electrode diameter (a 1/8-in, electrode you would grind a surface 1/4 to 5/16-in. long). Grinding the tungsten to a taper eases the transition of arc starting and creates a more focused arc for better welding performance. When welding with lower currents on thinner materials (those ranging from .005- to .040-in.), it is best to grind the tungsten to a point. A pointed tungsten allows the welding current to transfer in a focused arc and helps prevent thinner metals, such as aluminum, from becoming distorted. As a note, using pointed tungsten for higher current applications is not recommended, as the higher current can blow off the tip of the tungsten and cause weld puddle contamination.

Instead, for higher current applications, it is best to grind your tungsten to a truncated tip. To achieve this shape, first grind the tungsten to a taper as explained above, then grind a .010- to .030-in. flat land on the end of the tungsten. This flat land helps prevent the tungsten from being transferred across the arc and/or from balling.

In any application, the type and shape of tungsten you use helps determine the arc quality and welding performance you will achieve. Each of the six types of tungsten discussed here bring with it distinct advantages and disadvantages. That’s why, regardless of type of material you are TIG welding or whether you are using an AC or DC process, it is always important to choose your tungsten wisely for each application. Doing so can maximize your TIG welding success and is one of the best defenses against contamination and rework.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Electrode Tip Choices -Ⅰ

- Details

- Category: Tungsten Information

- Published on Thursday, 27 August 2015 17:16

- Written by Yahong

- Hits: 283

Balled tips are generally applied to pure tungsten electrodes and are suggested for being used in AC process on sine wave and conventional square wave TIG welders. To ball the end of the tungsten appropriately, simply apply the AC amperage recommended for a given electrode diameter and the ball on the end of the tungsten will form itself. The diameter of the balled end should not exceed 1.5 times the diameter of the electrode (a 1/8-in. electrode should form a 3/16-in. diameter end), as having a larger sphere at the tip of the electrode can reduce arc stability and/or fall off and contaminate the weld.

A pointed and/or truncated tip, for pure tungsten type, ceriated type, lanthanated type and thoriated type, can be used for inverter AC and DC welding processes. To properly grind the tungsten, use a grinding wheel specially designated for tungsten grinding to avoid contamination and one that is made of borazon or diamond to resist tungsten’s hardness. Note: if you are grinding thoriated tungsten, make sure you control and collect the dust, have an adequate ventilation system at the grinding station and that you follow manufacture’s warnings, instructions and MSDS sheets.Grind the tungsten straight on the wheel versus at a 90-degree angle to ensure that the grind marks run the length of the electrode. Doing so reduces the presence of ridges on the tungsten that could create arc wandering or melt into the weld puddle, causing contamination.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Specification for Tungsten and Oxide Dispersed Tungsten Electrodes for Arc Welding and Cutting Rounding-off Procedure

- Details

- Category: Tungsten Information

- Published on Thursday, 27 August 2015 17:12

- Written by Yahong

- Hits: 313

The following will tell something about specification for tungsten and oxide dispersed tungsten electrodes for arc welding and cutting rounding-off procedure.

For purposes of determining compliance with the requirements of this Standard, the actual test values obtained shall be subjected to the rounding-off rules of ISO 31-0:1992, Annex B, Rule A or ASTM E 29. If the measured values are obtained by equipment calibrated in units other than those of this Standard, the measured values shall be converted to the units of this Standard before rounding off. If an average value is to be compared to the requirements of this Standard, rounding-off shall be done only after calculating the average. In the case where the testing standard cited in the normative references of this Standard contains instructions for rounding off that conflict with the instructions of this Standard, the rounding-off requirements of the testing standard shall apply. The rounded-off results shall fulfill the requirements of the appropriate table for the classification under test.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Specification for Tungsten and Oxide Dispersed Tungsten Electrodes for Arc Welding and Cutting Packaging and Quality

- Details

- Category: Tungsten Information

- Published on Thursday, 27 August 2015 17:13

- Written by Yahong

- Hits: 256

Packaging

1. Marking of packages

The following information, as a minimum, shall be legibly marked so as to be visible from the outside of each package:

a. The number of this Standard, i.e., AWS A5.12M/A5.12:2009 (ISO 6848:2004 MOD);

b. Electrode diameter;

c. Electrode length;

d. Net quantity of electrodes;

e. Supplier’s name and trade designation;

f. Lot, control, or heart number.

2. Packing

Tungsten electrodes shall be packed so that their surfaces are protected from all damage or staining when they are properly transported and stored.

3. Marking of over-packing

Marking of any, or all, over-packing of unit packages with items listed in 11.1 shall be optional with the manufacturer.

4. Warning label

The appropriate precautionary information as given in ANSI Z49.1, latest edition (as a minimum) or its equivalent, shall be prominently displayed in legible print on all packages of electrodes, including individual unit packages enclosed within a larger package.

Electrode quality

The surface of electrodes shall be free of impurities, undesirable films, foreign inclusions, cracks, scale and other defects. Electrodes shall be internally free of foreign inclusions or anything else that would adversely affect the operation of the electrode. Oxide additions shall be sufficiently uniformly distributed throughout the electrode so that the operation of the electrode is not adversely affected.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Specification for Tungsten and Oxide Dispersed Tungsten Electrodes for Arc Welding and Cutting Standard Sizes and Tolerances

- Details

- Category: Tungsten Information

- Published on Thursday, 27 August 2015 17:10

- Written by Yahong

- Hits: 297

1. Electrode diameters, lengths and tolerances

Standard electrode diameters, lengths and tolerance are given in Table 1. Other diameters, lengths, and tolerances may be as agreed on between the supplier and the purchaser.

2. Electrode roundness

Electrode shall fit through ring gages sized for their maximum allowable diameter in accordance with Table 1.

3. Finish

Tungsten electrodes shall be supplied with a ground finish. The ground finish designates that the electrodes have been cleaned of impurities after they have been center-less ground to a uniform size. It shall be supplied with a bright, polished surface. The maximum surface roughness shall be 0.8 μm Ra[32 μmin AARH].

4. Electrode straightness

The electrodes shall be straight such that any element of its surface, over a specified length, must lie between two parallel lines of a specified spacing where the two lines and the nominal axis of the electrode of the electrode share a common plane. The specified spacing is 0.5mm[0.020 in] over a length of 100mm[4 in].

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com