Processing of Fine-grained Tungsten Carbide is Immature

- Details

- Category: Tungsten's News

- Published on Tuesday, 10 January 2017 14:15

- Written by tang

- Hits: 778

In recent years, a variety of new tool materials endless, but tungsten carbide cutting tools will still be widely used in the future for a long period of time, it is necessary to study the development of new materials preparation technology to further improve and increase the tungsten carbide tool material’s cutting performance.

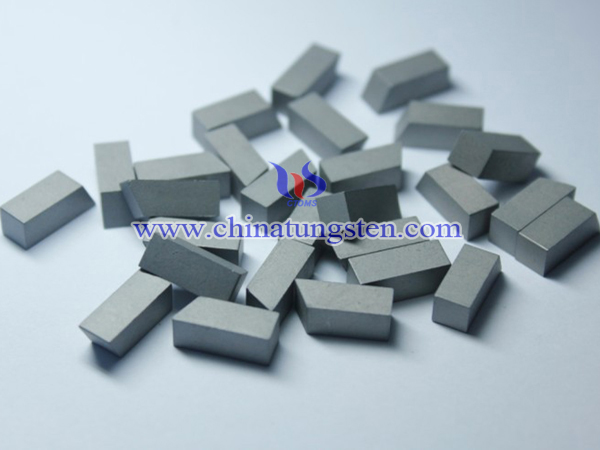

The strength and abrasion resistance of tungsten carbide cutting tools can be improved by refinement of hard phase grain size, increase of hard phase inter-granular surface area and enhancement of inter-granular bonding force. When the WC grain size reduced to sub-microns, the hardness, toughness, strength, wear resistance, etc. can be increased, and the required temperature can be fully densified. General tungsten carbide grain size is 3 - 5μm, fine-grained tungsten carbide grain size is 1--1.5μm (micron), ultra-fine tungsten carbide grain size can be up to 0.5μm (Micron, nanoscale).

As the grain refinement process is still not mature enough, so in the sintering process of tungsten carbide sintering is easy to grow into coarse grains, and grain growth will lead to the general strength of the material decreased, a single coarse WC grains are often Causing an important factor in material fracture.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

The Research Trends of Improving Tungsten Carbide Properties

- Details

- Category: Tungsten's News

- Published on Tuesday, 10 January 2017 14:12

- Written by tang

- Hits: 775

In the development processing, tungsten carbide encountered contradiction between strength and hardness, which is with high hardness but low strength, high strength but low hardness. WC particle size of tungsten carbide is always greater than its original particle size with traditional methods, and usually in a few microns.

However, many countries have encountered difficulties in the study of nano-carbide, the main problems are reflected in two aspects: First, the preparation of nano-WC-Co composite powder activity is very sensitive to temperature, in the high temperature will be immediately grown up. The current research and development trend is to improving the preparation of ultra-fine WC-Co composite powder method and improve the sintering processing. The compactness and uniformity of the tungsten carbide prepared by low pressure isostatic pressing sintering process are well, and the process has the advantages of short production cycle and small process loss.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Mobile Emission Catalyst Market Is Expected to Witness a Steady Growth by 2021

- Details

- Category: Tungsten's News

- Published on Monday, 09 January 2017 15:12

- Written by Cristina

- Hits: 843

Mobile emission catalyst helps in emission reduction from automotive and stationary engines from many vehicles such as cars, trucks, commercial vehicles and buses. It reduces emission of various gases such as carbon dioxide (CO2), carbon mono oxide (CO), hydrocarbons (HC), oxide of nitrogen (NOx) and other gases which are produced due to incomplete combustion of fuel.

Read more: Mobile Emission Catalyst Market Is Expected to Witness a Steady Growth by 2021

PBOC Warns of Bitcoin Volatility

- Details

- Category: Tungsten's News

- Published on Monday, 09 January 2017 15:18

- Written by Cristina

- Hits: 705

China's financial services authorities required major executives of the Shanghai-based bitcoin trading platform BTCC on Friday to rectify misbehavior in the trading of the virtual currency - and to raise awareness of risks as the value of bitcoins experienced wild fluctuations.

US Armor Piecing Designed for Penetrating 99A Tank

- Details

- Category: Tungsten's News

- Published on Wednesday, 04 January 2017 21:33

- Written by TungstenAlloy

- Hits: 1273

In the field of armor piercing, the United States is well ahead of all the countries in the world - including tungsten alloy armor piercing projectiles.

Read more: US Armor Piecing Designed for Penetrating 99A Tank

sales@chinatungsten.com

sales@chinatungsten.com