Tungsten Carbide Tools Classification and Use

- Details

- Category: Tungsten Information

- Published on Friday, 17 May 2013 10:55

- Hits: 2118

Tungsten carbide cutting tools include twist drills, reamers, boring tools, milling inserts, ball mill, blade cutter, taper cutter, smooth plug rod and step drill.

Tungsten carbide can be used as a wide variety of cutting tools. cutting tool Carbide The amount of tungsten carbide tool occupies about one-third of the entire tungsten carbide production.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Carbide Cutting Tools' Basic Knowledge

- Details

- Category: Tungsten Information

- Published on Friday, 17 May 2013 10:47

- Hits: 2207

The material of manufacturing the tool must have high temperature hardness and wear resistance, the necessary bending strength, impact toughness and chemical inertness, for good process, usually when the hardness is high, wear resistance is also high; high bending strength is with impact toughness. However, the higher the hardness is, the lower the flexural strength and impact toughness are. Tungsten carbide is a widely used tool material. Tungsten carbide indexable inserts are now coated with titanium carbide by chemical vapor deposition of titanium nitride, alumina hard layer or composite hard layer. Developing physical vapor deposition method can be used for carbide tool.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

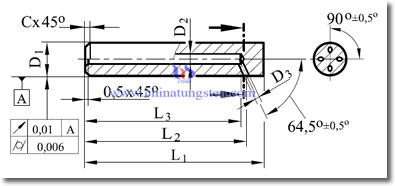

Tungsten Carbide Rod Standard

- Details

- Category: Tungsten Information

- Published on Thursday, 16 May 2013 09:55

- Hits: 2333

standard rods overview

solid rods

1 central coolant duct - broken link

2 straight coolant ducts

2 coolant ducts 30° helix

2 coolant ducts 40° helix

3 coolant ducts 30° helix

3 coolant ducts 40° helix

micro twisted coolant ducts

Special Rods

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten Carbide Rod's Introduction and Process

- Details

- Category: Tungsten Information

- Published on Thursday, 16 May 2013 14:33

- Hits: 2164

Tungsten carbide rod is tungsten carbide cutting tools, which applies different coarse grinding parameters, cutting materials and non-metallic materials. Meanwhile, the tungsten carbide rod can also be applied to a conventional automatic, semi-automatic lathe, and so on. The main process is milling → formula according to the intended use →wet milling →mixing →smashing →drying → sifting → crush → drying → mixed sieved and then drying → mix → granulation suppress → forming → low pressure burning → forming → ??cylindrical grinding fine grinding → packaging →detection size →putting in storage.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Welding Procedure Variables and Joint Configurations of Tungsten

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 May 2013 16:11

- Hits: 2195

Welding procedure variables control the welding process and the quality of the welds produced. Joint configuration is determined by the design of the weldment, the metallurgical analysis, and by the process and procedure required by the weldment.

Welding variables are selected after the base metal, filler metal, and joint configuration have been selected. The fixed welding variables include the type of filler metal, electrode type and size, the type of current, and the type of shielding gas.

The adjustable variables control the shape of the weld by affecting things such as bead height, bead width, penetration, and weld integrity. The primary adjustable variables for GTAW are welding current, arc length, and travel speed.

Secondary variables also aid in controlling the welding process, but it is more difficult to calculate the extent of effect. The secondary variables include work and travel angle and the distance the electrode extends beyond the end of the cup.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten Picture Center: http://picture.chinatungsten.com

Tungsten Video Center: http://v.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com