How Does Different Lanthanum Contents Affect Tungsten Electrode Performance?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:06

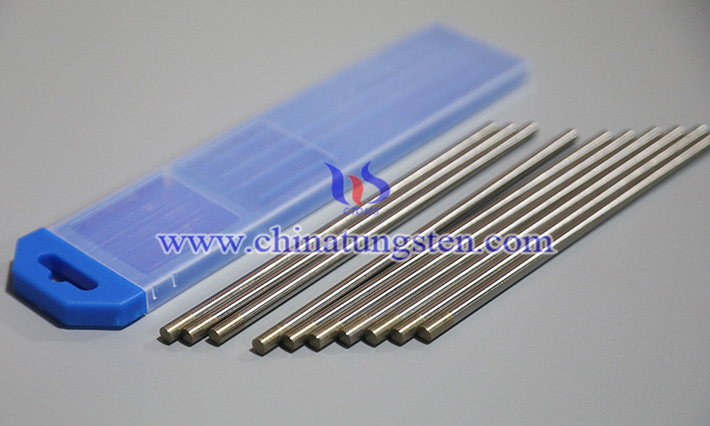

In modern welding technology, the choice of electrode material directly impacts welding quality, efficiency, and equipment stability. As a key consumable widely used in TIG (tungsten inert gas arc welding) and plasma cutting, tungsten electrodes, due to their high melting point, excellent conductivity, and ablation resistance, have become a vital component in industrial manufacturing.

In recent years, with increasing demands for environmental protection and welding performance, electrode materials doped with rare earth elements (such as lanthanum) have gradually replaced traditional thoriated tungsten products and become the new mainstream.

Adding varying proportions of lanthanum contents to these rare earth-modified products, their electron emission capability and high-temperature stability can be significantly improved. However, it's worth noting that varying doping ratios can have varying degrees of impact on electrode performance, directly affecting their application scenarios, service life, and welding quality.

Electrodes with low-proportion additions (such as 1.0%) are entry-level standard types with good arc starting performance, stable arc, and tip that is not easily burned. They are suitable for medium and low current DC welding, especially for manual or automated operations of conventional metals such as stainless steel, carbon steel, and copper. This type of product has a good cost-effectiveness and is widely used in general manufacturing and maintenance welding occasions.

A moderate ratio (e.g., 1.5%) represents a grade with more balanced performance. This ratio enhances the material's electron emission capability, making the tip more stable at high temperatures. While maintaining arc focus, it also improves thermal shock resistance. It excels in automated and pulse welding processes, making it suitable for applications such as aerospace, automotive parts, and medical devices, where weld continuity and consistency are paramount.

When the lanthanum doping ratio is increased to a high level (such as 2.0%), tungsten electrode exhibits enhanced ablation resistance and high-temperature shape retention, making them particularly suitable for high-current, high-load, and long-duration continuous welding scenarios. These products are commonly used for welding titanium alloys, heat-resistant steels, or special alloys, and are widely used in energy equipment, the nuclear power industry, and military manufacturing. However, excessively high addition ratios may also result in slightly delayed arc starting or excessive arc concentration under low-current conditions, so the selection process must be carefully considered based on specific process parameters.

In summary, different rare earth addition ratios directly determine the electrode's thermal stability, arc starting performance, and durability. Choosing the right material type not only improves welding efficiency but also extends the life of consumables and reduces maintenance frequency. For welding engineers and equipment maintenance personnel, understanding the specific impact of these compositional differences on welding performance can help them make more informed material selections in actual production, improving welding quality and overall production efficiency.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com