Ultrafine Tungsten Powder Preparation - Hydrogen Flow Rate Setting

- Details

- Category: Tungsten Information

- Published on Friday, 04 August 2017 10:19

The preparation of tungsten powder with tungsten oxide is a rather complicated physical and chemical process.

Especially, when the details do not in place, the preparation of ultrafine tungsten powder will not achieve the desired results, wasting all the previous efforts.

In the process of hydrogen reduction of tungsten oxide, hydrogen enters the furnace through the furnace tube and reacts with tungsten oxide. Tungsten oxide reacts with water vapor to form WO2 (OH) 2 which has large vapor pressure at 500~700℃, and it is reduced by H2 on the surface of reduced product, thereby thickening the particles. In addition, the water vapor will oxide the tungsten powder, of which the oxidation products will be reduced on the surface of tungsten oxide and thicken the particles. The thickened particles get further reduced, and finally get the coarse tungsten powder.

How to eliminate or reduce the probability of the above incident occurs? This requires setting the hydrogen flow in the reducing furnace.

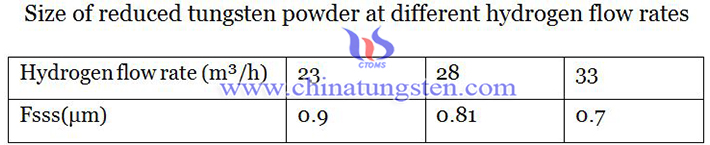

In the reduction furnace, the H2 flow rate is small and the reaction is slow. Tungsten oxide at low temperature cannot be completely reduced to tungsten powder, but when the temperature is too high tungsten oxide will quickly evaporate. As the tungsten oxide vapor increases, more gaseous hydrated tungsten oxide WO2 (OH) 2 will be generated, and the fine tungsten powder is re oxidized, resulting in a coarser particle size of tungsten powder. Therefore, to obtain finer size tungsten powder, it is necessary to increase hydrogen flow. With the increase of hydrogen flow rate, the particle size of tungsten powder decreases. AS a result, when preparing ultrafine tungsten powder, larger hydrogen flow should be adopted than that of ordinary tungsten powder.

Of cause, the hydrogen flow rate cannot be too large, or the airflow will take away most of the materials, resulting in great waste. In general, the excess range of hydrogen is between 2.5-40 times the theoretical quantities. As for how to handle in place, it is depended entirely on the production practice and experience.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com