Mould Pressing Pressure Lost

- Details

- Category: Tungsten Information

- Published on Tuesday, 18 July 2017 15:10

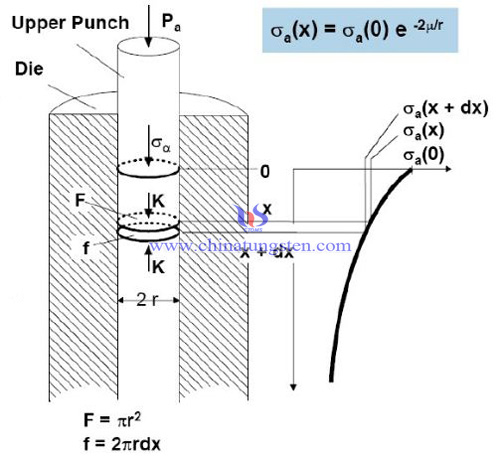

In the mould pressing process, because the mutual friction between different powder particles and die walls, lead to stress on the punch transmit out of accordance with Pascal’s principle, receive different stress in various point of briquetting.

It’s generally speaking that the location which further away the pressing punch is the pressure is more smaller, this pressure lost called pressure drop.Friction between different powder particles and die walls is the mainly reason lead to no uniform pressure distribution. The thinner the powder particle is the more complex the shape will be, the bigger the pressure drop is, and the further distance away punch will be.

Pressure Lost Formula:

P'=Pexp(-4μξ H/D)

P’ is the pressure which receives from bottom of mould.

P’ is the punch pressure.

Μ is the friction coefficient between powder and die wall.

H is the compaction height

D is the compaction diameter.

In view of the consuming elastic deformation of the stress:

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com