Tungsten Concentrate Gravity Separation – Roll Crusher

- Details

- Category: Tungsten Information

- Published on Wednesday, 05 July 2017 17:08

After artificial beneficiation, tungsten concentrate will enter gravity separation process. Crush means crushing coarse tungsten concentrate in to relative specification and enters next step of tungsten concentrate gravity separation. It needs to be completed by crusher.

Crusher has four types includes jaw crusher, cone crusher, roller crusher and impact crusher. Every tungsten mine can choose proper crusher according to its realistic condition.

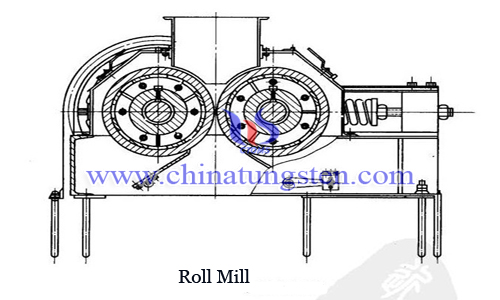

As we all know, tungsten concentrate is fragile, it should be treated wildly. Roll crusher is an equipment utilizes two break rolls to squeeze and crush materials, its unique processing method results in coarse grain, it is adjusted to requirement of tungsten concentrate gravity separation of grain size, so it is perfect for the process of next step.

Roll crusher has advantages of big crushing ratio, low noise, simple structure, the crushed material is uniform in grain size, smart protection carrier and save. It is widely used in some tungsten mine in south of Jiangxi Province.

It also has shortcomings. The equipment is big which takes a large space. During working process, the abrasion on the surface of roller is uneven. Sometimes it needs to be shut down and repaired. So it affects efficiency of tungsten concentrate gravity separation. That is the reason why its application field is smaller than jaw crusher.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com