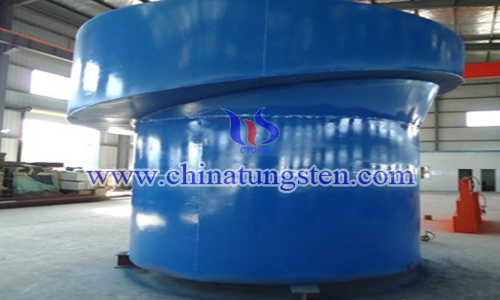

Tungsten Scheelite Flotation Equipment – Backflow Non-filling Type Flotation Column

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 June 2017 17:44

Flotation column is a new type of tungsten scheelite flotation equipment, it has a simple structure, small footprint, low cost, high degree of automation, low infrastructure investment, good flotation index and many other advantages, and gradually become mainstream in tungsten ore flotation.

In diverse flotation column, backflow non-filling type flotation column is the most popular one. It has unique design and structure, small floor space, low energy consuming, small maintenance amount and stable operation.

Backflow non-filling type flotation column includes mine supply device, tailings emission device, column, inflation device, foam washing water device and industrial automation control system.

Processing fine mineral grain is the advantage of the machine. Its working principle is using mineral particles and micro-bubble counter-current flow of smooth contact, providing chance to capture mineral grain. Mineral grain and foam moves in reverse, absolute speed is low but relative velocity is high, turbulence scale is also low, bubble in the column is fine and even, surface area is big, under current condition it has more opportunity to contact with mineral grain, improves flotation speed and recovery rate. At the same time, bubble layer is thick in column, it can be adjusted. Plus the reverse cleaning function of spray water can largely promote concentrate grade.

Backflow non-filling flotation column has been proved in a molybdenum tungsten mine in Henan province. It shows that the mine use the machine to float molybdenum tailings containing 0.05% WO3 and obtain coarse tungsten concentrate with 1.3% WO3, recovery rate is 75%. It not only saves cost but also gains more profit by recovery.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com