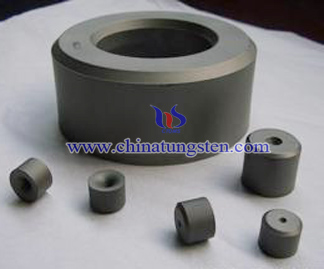

Tungsten Carbide Tube Drawing Die

- Details

- Category: Tungsten Information

- Published on Friday, 26 August 2016 17:56

Tungsten carbide tube drawing die uses tungsten carbide as mandrel and outer inlaid steel, which plays an important in drawing copper and steel tube. It has higher requirement to surface roughness, generally polished to mirror and no cracks and other defects. Common grades are YG6, YG6X, YRL 10, YG8, YG15, etc. It uses tungsten carbide as mandrel, which has high hardness, toughness, low friction coefficient, excellent wear and corrosion resistance and mainly used for drawing copper, steel and other metal tubes. There are some specifications of tube drawing die as follow:

|

Grade |

Density g/cm3 |

Hardness HRA |

Strength MPa |

Application |

|

YG6 |

14.95 |

90.5 |

1900 |

Used for drawing non-ferrous metal rod within φ20.00mm or tube within φ10.00mm. |

|

YG6X |

14.95 |

91.5 |

1800 |

Suitable for the production of less than ¢ 6.00mm bore drawing die. |

|

YG8 |

14.80 |

89.5 |

2200 |

For the production of drawn steel and non-ferrous rod and tube of metal die. |

|

YG10 |

14.50 |

88.5 |

2400 |

|

|

YG15 |

14.00 |

87.0 |

2800 |

For manufacturing steel rods and tubes with high shrinkage. |

In addition, it should be notice that when we are using tungsten carbide tube drawing die:

1. Equipment select: According to the drawing material and equipment, allocate the compression ratio of each tube to determine the angle of the workspace;

2. Pre-treatment: such as cleaning, descaling, annealing, phosphate, etc., to ensure cleanliness of materials;

3. Drawing agents: choose proper drawing agents (lubricant, oil) to cool the tube drawing die;

4. Aging and replacing: Avoid the abuse of the tube drawing die and timely replace the mold.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com