New WO3 Denitration Catalyst Anti-Alkali Metal and SO2 Poisoning

- Details

- Category: Tungsten Information

- Published on Tuesday, 26 July 2016 17:51

Earlier this year, Tang Xingfu, the professor of environment catalytic group, Environmental Science and Engineering of Fudan University, developed a new denitration catalyst technology of simultaneous anti-alkali metal and SO2 poisoning. Research data in China and foreign shows that compared with the primary source, a secondary-generation components account for more than half the proportion of PM2.5 and has a higher percentage at the time of the occurrence of haze. This technology can effectively control NOx which is the PM2.5 precursors emission, and have an important positive role in the reducing of particulate pollutants in the atmosphere to secondary formation of NOx conversion.

Earlier this year, Tang Xingfu, the professor of environment catalytic group, Environmental Science and Engineering of Fudan University, developed a new denitration catalyst technology of simultaneous anti-alkali metal and SO2 poisoning. Research data in China and foreign shows that compared with the primary source, a secondary-generation components account for more than half the proportion of PM2.5 and has a higher percentage at the time of the occurrence of haze. This technology can effectively control NOx which is the PM2.5 precursors emission, and have an important positive role in the reducing of particulate pollutants in the atmosphere to secondary formation of NOx conversion.

Both SO2 and NOx are the important precursors of forming secondary atmospheric particulate matters, China has put the great effort on developing the desulfurization technology to improve air quality since the 1990s, haze phenomenon has not been significantly improved although the emissions of SO2 decreased significantly. The study found that solve the haze problem should do both desulfurization and denitrification simultaneously, and coordinated control from the original source to control the emission of pollutants.

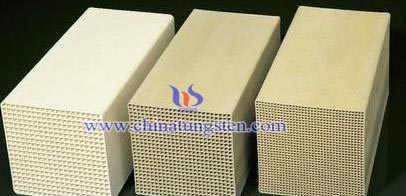

The current mainstream technology for the removal of NOx is SCR with its core technology of WO3 denitration catalyst. Tang Xingfu group has establish the intrinsic alkali metal ion exchange - type ligand poisoning mechanism in early 2015, after the unremitting efforts, they finally broke through the bottleneck that the traditional denitration catalyst is difficult to apply in the high alkali or alkaline earth metal coal or biomass fuel flue gas denitrification technology, to develop the new denitration catalyst which can resistant alkali metals and SO2 poisoning at the same time. This catalyst has both catalytically active and alkali metal trapping sites, wherein the alkali metal trapping sites can capture the alkali metal particles; with the properties of this new denitration catalyst, the alkali metal will be spontaneously moved to the trapping sites, even though the alkali metals have pre-empted the catalytically active sites, and then re-release the catalytically active sites to ensure the catalytic activity. In addition, the combination of an alkali metal and trapping sites is very stable and does not affect the denitration reaction on the active sites. According to reports, the serve life of this new type denitration catalyst has increased more than 10 times of that of the conventional catalyst.

WO3 as a co-catalyst of denitration catalyst, plays the role of enhancing the ability of anti- alkali metal and sulfur dioxide poisoning of the catalyst; at the same time, WO3 will improve the thermal stability of titanium dioxide to increase its anti-sintering performance and to prevent the denitration catalyst in an instant high temperature sintering occurs at ambient which makes part or all of the catalyst deactivation, and thus enhance the catalyst activity and prolong the service life of the catalyst.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com