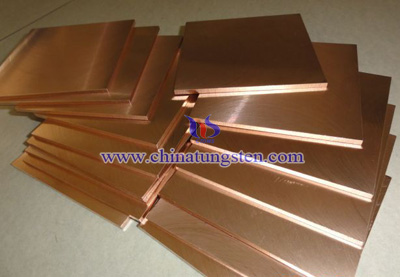

Tungsten Copper Sheet Sintering Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 June 2016 14:55

Tungsten copper materials perfectly combine high hardness, high melting point, high strength, low coefficient of thermal expansion and excellent wear and corrosion resistance of W with high plasticity and excellent thermal and electrical conductivity of Cu. Furthermore, it has another advantage that other material difficult to achieve: there is a great difference in the melting point between W and Cu (W-3380℃, Cu-1083℃), at a temperature exceeding the melting point of Cu, copper evaporation can take away the most of heat and keep the matrix working normal. So it is also called sweating heat sink material.

With the development of electronic devices now tend to be miniaturized and high-power, heating and cooling is an inevitable process of the devices. Tungsten copper alloy with superior performance to meet the cooling requirements of high-power devices, and it may also adjust the coefficient of thermal expansion, and microelectronics devices of different semiconductor materials are well matched connection, so as to effectively prevent heat stress thermal fatigue damage caused. Therefore, in some LSI (large-scale integrated circuit) and high-power microwave devices, tungsten copper sheet has a broad prospect in electronic packaging substrates, heat sinks, connectors and other microelectronic housing material.

Theoretically, as heat sink material, tungsten copper sheet has a strict requirement of theoretical density, usually higher than 98% and the thickness less than 1mm, which conventional PM (powder metallurgy) is difficult to meet the increasing requirements. Recent years, the relevant researchers and scholars have studied in ultra-fine powder fabrication, densified process and alloy molding technology. For tungsten copper sheet sintering process, Surface wettability of densification, microstructure and properties of the alloy a great impact, and tungsten copper two-phase sintering temperature depends on the wettability of tungsten and copper two phases. Through the experiment can be found that sintered at 1200 ℃, tungsten particles agglomerate, with copper and tungsten particles did not enter the group, there are many small voids between the particles of tungsten and copper group phase, which indicates Cu has poor wettability at this time; when sintering temperature up to 1300℃, the wettability of Cu has improved, so it can immersed in the tungsten particles, which is beneficial for flowability and rearrangement of W grains. With the increase of sintering temperature, then Cu phase occurs gathering, that is copper pool of depression phenomenon, inter tungsten particles re-agglomerate and grow interconnected to provide the conditions so that the density of tungsten copper alloy in high temperature sintering stage quickly increase.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com