Tungsten Carbide Rotary Burrs Description (1/2)

- Details

- Category: Tungsten Information

- Published on Monday, 09 May 2016 16:50

Tungsten carbide rotary burrs consist of the hard phase WC and the binder phase Co, which is also known as tungsten carbide assorted cutter or high-speed molding cutter and so on. It is mainly cooperated with high-speed electric grinder and pneumatic tools. Due to its processing hardness can reach more than HRA 85, it can be widely applicable to the most of materials, such as common cast iron, steel, copper, aluminum, marble, alloy steel, carbon steel and other metal or non-metal materials. The principle is that tungsten carbide rotary burr clamped on high-speed rotary tool, which achieves the cutting performance by the pressure and feed rate controlling.

Since tungsten carbide rotary burr has excellent cutting properties and long life span, it has a broad application prospect, such as finishing for metal mold cavity; castings, forgings, welding components the existence of flash, burrs, weld cleaning; A variety of mechanical parts chamfering, machining grooves and keyways; pipeline, flow channel, the inner surface of the hole parts cleaning and grinding; the sculpture of A variety of metal or non-metallic materials, etc.

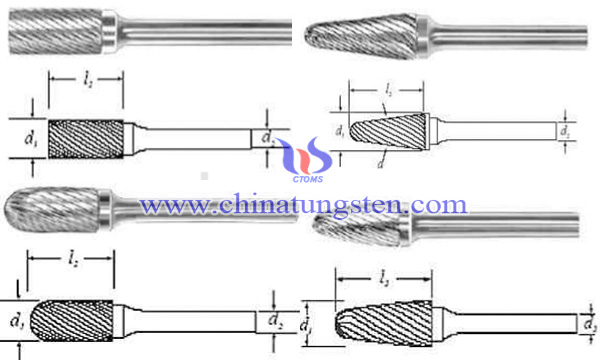

According to the shape of head, tungsten carbide rotary burr can be divided into cylinder (A), cylindrical-shaped (C), round arch (F), spherical (D), round-shaped torch (H), 90° conical (K), 60° conical (J), 38° conical (M), arc-shaped disk (T), inverted conical (N), tapered round (L), tapered tip (M), drum-shaped (B), ellipse (E), curved arrow-shaped (G), tapered flat-shaped (S), half arc-shaped (W) and so on. And the common grades used in tungsten carbide rotary burrs are YG6, YG8 and YG10x, which has excellent impact toughness, wear resistance and is suitable for cold heading, cold punch, cold mold fabricating.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com