Tungsten Copper Sintering Technologies Comparison (2/2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 April 2016 16:05

In order to improve mixed-pressing, relevant scholars uses activated agent (Ni, Pd and other activated elements) to increase the solubility of W in liquid phase, which is beneficial for the sintering process. However the additives have a bad influence on the electrical and thermal conductivity of tungsten copper products. Pressure sintering is a kind of secondary processing after sintering, especially for the conditions that one-step forming can not meet the requirements. Although hot pressing, repressing and re-sintering and HIP (Hot Isostatic Pressing) can remarkably improve the properties of tungsten copper composite material, they are limited by the costs and the efficiency. In addition, using hammering or cold rolling of tungsten-copper composite material for secondary processing can greatly increase the density and mechanical properties of the material. But when the content of W is higher, the ductility of tungsten copper will decrease and the difficulty of machining will increase.

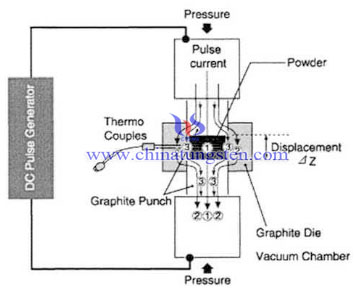

Spark Plasma Sintering (SPS), which is also known as Plasma Activated Sintering (PAS) or Field Assisted Sintering Technology (FAST). According to different powder media, SPS can be divided into conductive and non-conductive, there is a big difference in mechanism between them. Generally, conductive SPS will produce a large amount of Joule heat generated by DC pulse current graphite mold; and the current through the powder will induce electric discharge between powder particles and arouse plasma. With the increasing density of plasma, High-speed reverse movement of the particle surface of the particles have a greater impact, so that the gas adsorption of escape or break an oxide film, so that the surface to be purified and activated, will be conducive to sintering. However, instantaneous high temperature generated by the discharge causes evaporation and melting of the grain surface, the grain at the point of contact to form sintered neck.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com